Okay, now we're ALMOST getting somewhere.

Here's the next battle and I don't even know who to put my money on yet.

I'm throwing in a new factor into the equation so here goes.

My next test will be with Menz PG and SIP against Meg's M105 and Gloss It Evo Cut.

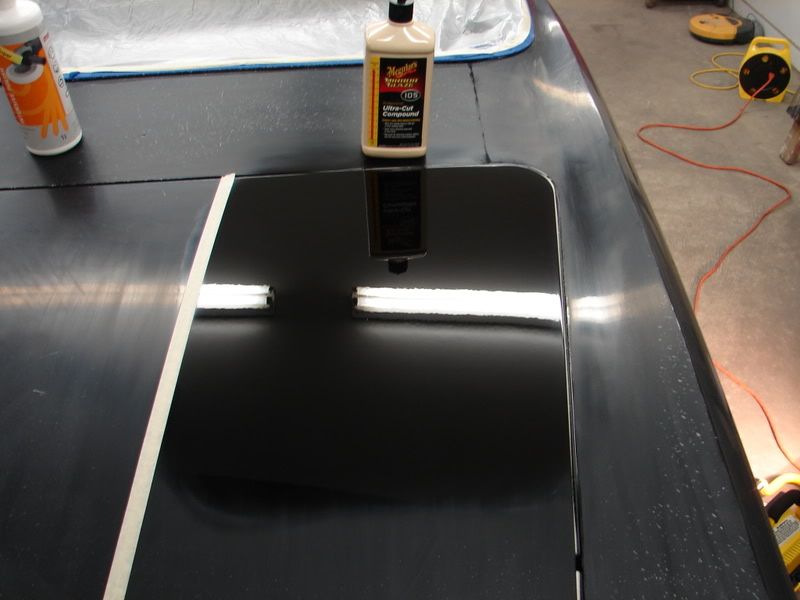

Here's the new test panel.

The unbias judge called 500W halogens.

The victom, custom painted 66 Lemans passenger rear panel

Let's see what happens....

First off

M105 on a LC purple foamed wool pad. I put it on extra heavy cause I know it doesn't have a very long working life so I like to put it on real thick as you can see in this pic. fyi

Dobbing it around and then a spritz with water.

Working it in as before,

spread quickly at 600rpms, then up to 1700 to break it down with slow passes working it in slowly then once broke down, turn speed down to 1100 then 700-900 to jewel a little.

Spreading it around.

Working it in and breaking it down, then jeweling.

Final results.

I consider that entire step as One Pass.

Not bad, if you look closely you can still see some holograms near the bottle just over the lip of the fender.

Now with the

Gloss It Evo. Cut over top M105 to finish down a bit more. Same process as before,

white LC pad, dob it, spritz it, spread it at 600, then up to 1500 then jewel at 1100 and 900rpms.

Still some swirls left behind but very very nice finish. This will be hard to beat.

Onto the other combo of Menz PG and SIP with exact same technique and process as above.

Menz Power Gloss put on moderately thick, but not quite as thick as the M105

Working it in. The Menz PG seems to have a longer work in life so I could play with it a bit more which I find more effective when removing defects.

As expected the PG does not finish down as well as the M105 but does seem to have a bit more bite and I can work it in longer so it's a tough decision between the two heavy hitters.

Now for the SIP and white pad with the same process as the above test with the Evo Cut.

Wow, nice results between both combo's.

As you can see in both tests the finish down was great, but there was still some fine deeper scratches that neither combo was seeming to really get under to correct 100% so I will try one more combo.

Also it should be noted that some panels had worse and deeper sanding marks then others as there was 3 different people sanding the car and the car only had a few runs to remove so please know that I can see much better with my eyes then what the camera is showing you so even if one picture looks better then another and I tell you otherwise it's cause I visually inspect the whole section where the camera only shows you a small portion of that section.

Now for the final test which ended up being the winner I chose to do something different and combine my two heavy hitters and see what happens....

Now for Menz PG and Meg's M105.....

Results were better, deeper cut and great finish so I went with this combo. I didn't document it like the others but I used the same process.

Even though there's a couple deeper swirls in this pic the over all section had little to no sanding marks or swirls in it. Plus I knew I would have to finish the whole car down with Menz Final Polish II anyways.

I think we have a winner after 3 hours of testing.....

Menz PG with a LC purple foamed wool pad at 1700 and Megs' M105 with a LC white pad at 1500, jeweled and then finish down with Menz FPII with a LC black pad at 1100-1200 and jeweled at 700-900rpms.

Now to start on the car.....:waxing::grinno::2thumbs: