Barry Theal

New member

I wonder how they work? I also wonder if anyone has actually seen them yet?

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

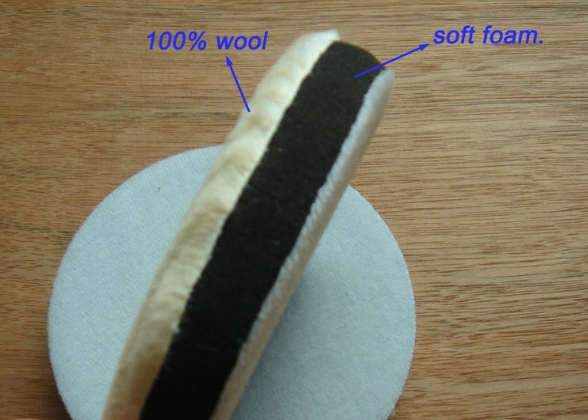

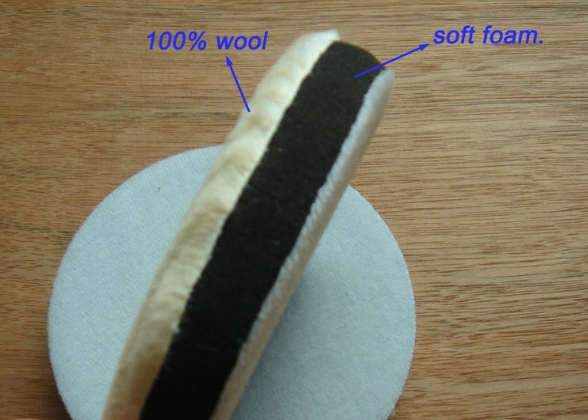

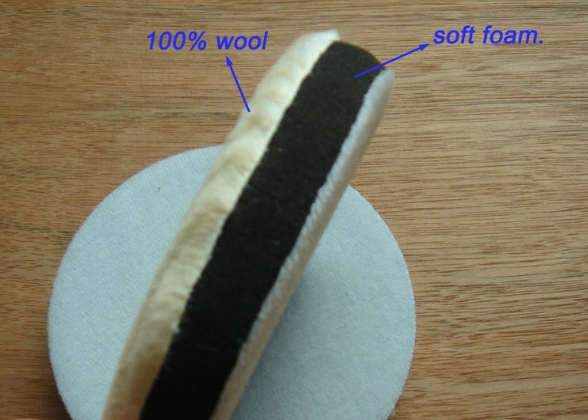

Barry Theal said:Yeah here is a new Microfiber thats not out yet. lol But I'm just curious about the wool. :2thumbs:

Barry Theal said:

Barry Theal said:Yeah here is a new Microfiber thats not out yet. lol But I'm just curious about the wool. :2thumbs:

Barry Theal said:Yeah here is a new Microfiber thats not out yet. lol But I'm just curious about the wool. :2thumbs:

WhyteWizard said:The electrified sheepskin pads work great on a rotary polisher or on a forced rotation dual action. I think they'd cut faster than microfiber because the it's my experience that polishes generally cut faster when used with wool than with synthetic or microfiber.

The shorter nap would work better on the random orbital because the nap looses some of its action against the paint as the backing plate changes direction and the fibers stay in place till the tension between the attachment on the pad and the paint is re-established and they start getting pulled across the paint again. It's like a brush against a carpet, if you just move the brush back and forth a little, the bristles stay in place. As you know, I'm not a fan of random orbitals because I don't believe they get much done, but since they have a following around here, I'm just saying.

David Fermani said:Not so sure I'd buy ino that logic without trying these pads 1st. With many of the abrasive packages in certain polishing compounds these days marketed for DA use (Meg's especially), they seem to work better with a material that won't allow the abrasive particles to soak into the pad. Micro Fiber pads provide excellent geometry by keeping the abrasives on the outer surface of their short nap and this creats an effective leveling device. At the end of the day, what makes for great cutting action is a pad that acts as a non-absorbing abrasives carrier rather then one that tends to over-absorb thus reducing the cut by trapping in the partical clusters within. Again, just my opinion, but looking forward to trying these pads out.

SVR said:Hi guys, Fermani I agree with your comments above.

I have stopped buying wool pads entirely now and am keeping the wool pads that I have

Truth be told I haven't used them since investing in surbuf pads then the optimum microfibres which are absolutely awesome, then the rayon pads that came from stainless steel polishing and glass polishing worlds. I use them as a deep straight line scratch remover and corrector for hard paints. they really work great with a rotary.

main reason Im not using any wool is that I'm using the Dynabrade heads mostly today as well some pneumatic palm sized power tools from dynabrade and my big 8 inch 1.5 inch nap wool pads dont really fit on it and the time came for me to leave them behind and move on. the rotaries only come out to play in their traditional form (ie no dynabrade head) when doing a four step or more refinishing service. they are used for the second last step to jewel the paint with either a flexipads ivory foam pad or some other 80, 90 and 100 ppi pad. I'd never use a rotary in standard form anymore for the first or second step when the dynabrade head on it just blows it away with it's ability to remove OEM factory pig tail prep marks no matter how miniscule, all defects and retexturising the paint (up to 99% peel removal) with microfibre polishing pads and the denim/velvet at speed 6, 5, 4 and 3.5 with Xpert for 7 to 12 mins per typical working area.

I think microfibre, surbuf, rayon, denim and velvet pads have made wool obsolete. we are nearly there with foam too.

Am only using foam for the finishing and Jewelling steps of my refinish work

And yes I do love those denim and velvet pads. They correct much faster than wool and reduce orange peel by nearly 99% with the Xpert products and finish down on 98% of paints with 0% marring even by rotary. only improvement from there on is colour, depth and clarity with softer materials

I do use a soft interface pad between a rayon pad and the backing plate on the dynabrade head or rotary sometimes as they tend to walk around sometimes. they glide like a foam pad when an interface pad is there. cheaper than foam pads too by a mile

thanks again to barry for the dynabrade heads. wouldnt of known about them without you mate. best thing I've ever had in my shop

Think there is too much focus on cut these days by many people and not enough on finish

make the polishes lighter and the pads stronger and smarter - thats where I've headed with Xpert and the MF's, rayons, surbufs and denim/velvet. marr free finish with any pad