Junebug

JAFO

Really Todd? Other than getting into it with the guy about teflon I don't recall any posts - maybe it was Brian.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

JuneBug said:If any of ya'll have the time - go back to the beginning and read this thread, I did, and you have to wonder why now, after 6 months has passed that the basic methods and processes are questioned.

TH0001 said:Out of curiosity, what qualifies you to make that statement. Several product formulators I spoke to in the past would likely disagree with that statement, as too much product can cause a number of problems when you are relying on chemical action for produt bonding.

Over application (from what I have been told) can directly effect solvent outgassing, polymer linking, and cause chemical overload. That is some of the solvents can become trapped in the solution, and when wiped away, they become re aggitated back into to the cured product, which removes and weakens the protective layer.

I have spoke to probably six different product forumlators and manufacterors and they agree that with modern sealants, over application is the root of poor product performance.

TH0001 said:I'm really not sure the point of this thread...

My new car, washed with dawn, beaded water for months with no wax or sealant, so I'm not sure about the results. I was excited orginaly by this thread but feel that it falls short on many levels.

David Fermani said:One of the reasons for doing this test is to verify each product’s longevity. Please note that I have a mixture of products that are discussed on this forum as well as products that aren’t. I (along with most of you) would like to see how some of our products stack up against some of the “smoke and mirror� / “snake oil� products that have developed a bad reputation in the enthusiast’s mind. I’m tying to do a legitimate test to see which product really holds their ground and could possibly earn the respect of some the non-believers (if such prevails).

TH0001 said:Also, the application method used was beyond terrible and really has me questioning how much experience the OP has with applying products. One pea sized drop is enough to do a section of the car, yet it seems that 10-30 times too much product was used in each section.

TH0001 said:I think it is painfully obvious in this thread that he isn't as learned as many hear when it comes to the appication and removal of modern crosslinking polymer's which require a thin coat and minimial product usage for maximum curing.

Jesstzn said:One of the flaws was the Zaino application .. it need either ZFX or Z1 to be used with it. And as with most sealants more isn't better.

Jesstzn said:Myself I agree with the poster above (TH0001) .. the application methods were flawed. And the beading I am seeing to me is saying there isn't much if anything left at all.

MakitaNinja said:I haven't used half of those products he's testing, but I believe the problem area lies in the product amount used. It seemed like an awful lot to me, compared to every paint sealant I often use, he used way too much which would have the ability of giving off false results, as the product wasn't used correctly to begin with.:closed:

TH0001 said:Several product formulators I spoke to in the past would likely disagree with that statement, as too much product can cause a number of problems when you are relying on chemical action for produt bonding.

Over application (from what I have been told) can directly effect solvent outgassing, polymer linking, and cause chemical overload. That is some of the solvents can become trapped in the solution, and when wiped away, they become re aggitated back into to the cured product, which removes and weakens the protective layer.

I have spoke to probably six different product forumlators and manufacterors and they agree that with modern sealants, over application is the root of poor product performance.

Alfisti said:Plus the fact that no label (that I know of) recommends caution in this area. If it would make their product perform poorly and effect consumer satisfaction, I would think they would caution against it...like they do about not moistening the applicator on some products.

TH0001 said:Of course applying some product to the sides and others to the top completely skews results as I have seen more then 1 wax continue to bead strongl on the sides while the horizontal sections where flat....

Black240SX said:Here is an idea: mark off a section of each area, then clay and rewax it with the product you originally used in that area.

That will make apparent the degradation that has occurred.

detailjohn said:So which do you feel offered the best protection?

JuneBug said:I think it's one of the best posts that we've been privilaged to see. I reread the original part of this thread and I didn't see where David "flawed" anything. I suspect that some didn't agree with the outcomes but that's just their opinion. Perhaps if there was a clear winner or loser then this test might "seem" more signicant to some, but for me it just confirms that there are a lot of really good products and you have to decide what fits your idea of best. Is it look? ease of use? price? etc. So opinions will come and go but I just want to say - Thanks David! You did a excellant test.

GatorJ said:David: First, thank you for your efforts...this has been a lot of work on your part. Could you please clarify something for me? Do I understand correctly that 1Z Einsett Glanz and Menzerna FMJ were only applied to vertical surfaces and not horizontal ones? I also live in Florida and it has always been my experience that the horizontal surfaces take far more of a beating in our sun than do vertical panels. Curious about your thoughts. Again, thank you for taking the time to do this.

detailjohn said:How did the Mark-V sealant fare? Just curious.

charger17 said:I'd love to know which manufacturers told you that. Just how thick do you have to apply a product for the solvents to become trapped? I can appreciate that if you try and remove the residue before the product has hazed over then you may also remove some of the polymers, but as David stated in his original post, he let the products cure for an hour before removal, enough time for even the slowest drying solvents to evaporate.

David Fermani said:Well, it’s actually to determine the durability of each product based on how long it beads water. I mentioned this on page 3:

In all honesty, I’m somewhat disappointed with the results of my test too. I was hoping for distinguishable variances between each product but it hasn’t quite happened the way I had planned. I was also thinking that the untreated sections would flatten out really fast. But, because I prepped the surface so well AND because it’s a new vehicle (no surface degradation), the surface tension throughout the whole vehicle is causing the outcome to be undefined. All the initial small, tight and round beads dropped off way before the 6 week point on all the panels. Does this mean that all the protection and/or product has failed or stopped working? There’s no way of knowing! If you compare beading on protected panels from the 6 week mark to the 6 month mark, there’s really not *much* of a change. This again could be attributed to surface tension and/or product remaining. Again, from discussing this test with a few formulators & enthusiasts, it can’t be determined. I’ve also been told that it’s very difficult to do a product comparison on a vehicle with so many different surface/body lines. A better way would be doing it on panels that are totally flat and with large surface areas. Again, sorry this thread isn’t giving any real world outcomes. What it does show, is the power of low surface tension and how it could play into how we view our results.

Beyond Terrible & Painfully Obvious? That’s way off & not accurate in any way. I spoke to Sal Zaino in great depth today for about an hour. He was familiar with this thread and had nothing bad to say about my test and/or the amount of product I used. He specifically stated that applying too much product will NOT affect the performance/longevity. He actually laughed when I told him what was stated here (above)! I also learned that if a sealant is allowed to haze/dry properly, it won't make any difference how thick the application is. You'll still get the same amount of product bonding to the surface. If the solvents don't fully evaporate before removal (i.e., if you try to buff it before it's dry) then yes it may cause some of the polymers to be removed with the polish powder. The solvents will never become trapped just because the layer is thick, they will just take longer to dry out. Once they've dried, the polish powder can be buffed off and the only disadvantages will be that you'll have wasted product and made more work for yourself in the removal.. Sal did say that using ZFX with Z2 will definitely give it much more durability, but at the time of the test, I failed to research this. So, bottom line; I feel people are grasping onto incorrect information(rumors?) and leading to more misinformation. The products I used were 100% totally dry and applying them a little heavy didn't hurt this test. Sorry.

Todd – I’d really like to know who the 6 formulators/manufactures are so I can maybe discuss this with them too. I enjoy and try to capitalize on every chance I get in respect to learning from truly knowledgeable professionals. Can you please disclose this list?

Also, Sal mentioned that it's vital that a vehicle gets clayed for a proper application and bonding of sealants. I noticed in your recent sealant test you didn't clay? Why? Even though a finish is washed/ polished and Prep-Sol'd; you still will have bonded surface contaminants that will interfere with a products abilty to cross-link & bond to the surface. Especially on a 7+ year old vehicle.

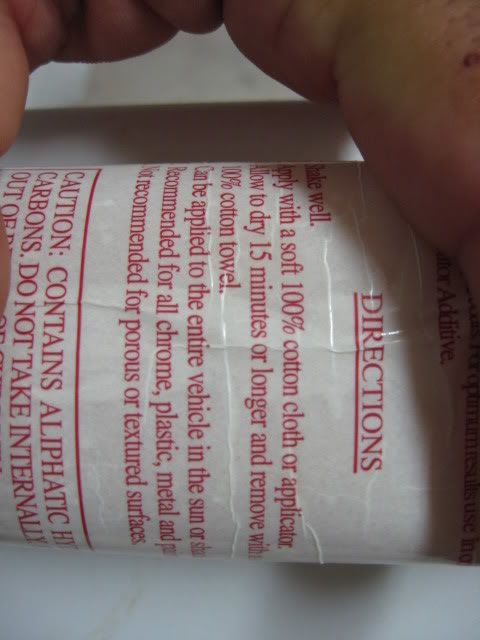

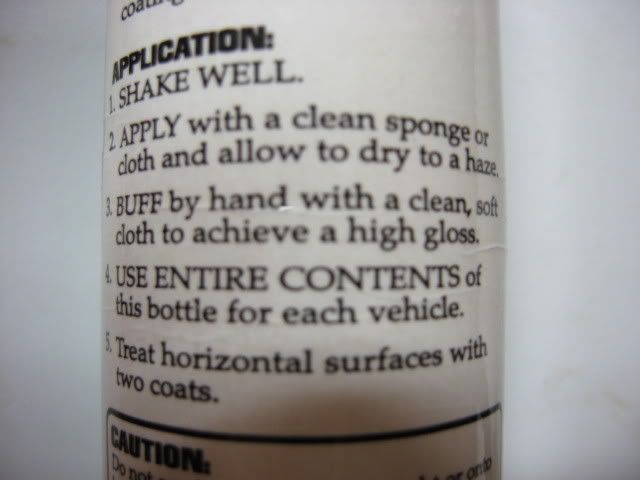

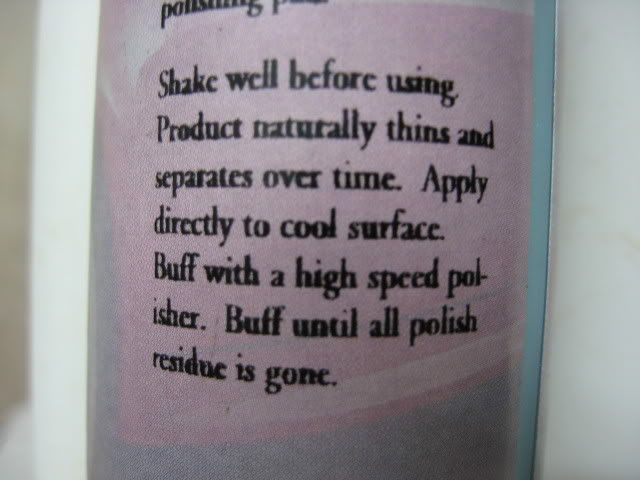

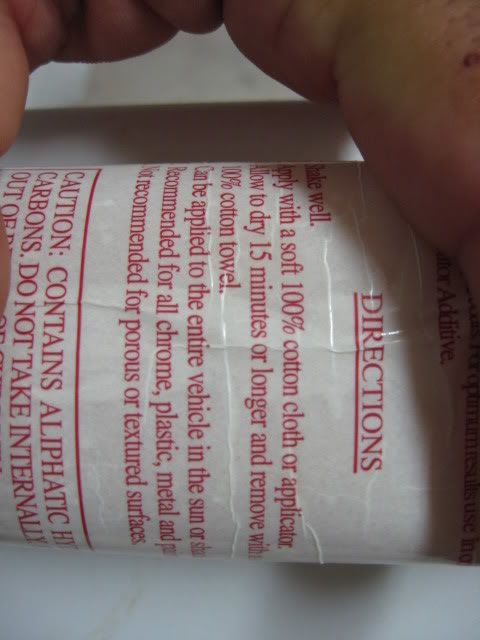

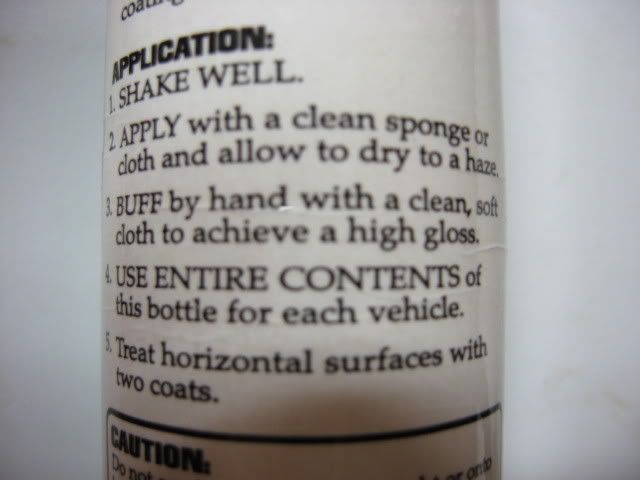

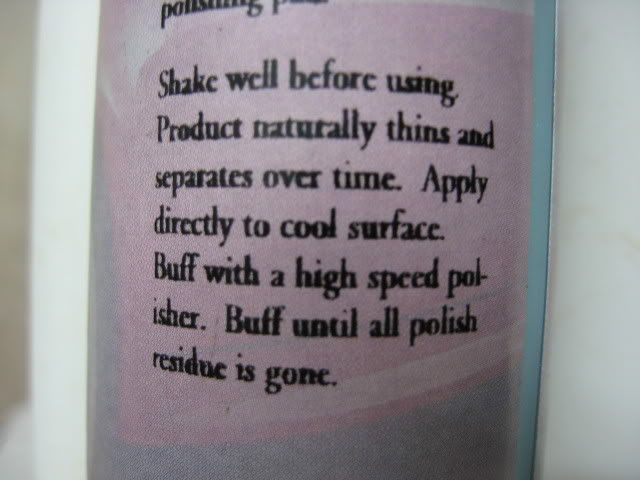

Right. You’d assume that if it was that detrimental to its performance, they’d list it? I'd have to say that it would be worse to under apply the product than over apply it, as you could end up with some areas that have no coverage at all. Here’s the bottle labels on some of the products I used. Again, none list amounts to use and/or that using too much to be a problem.

All 8 products were applied to the vertical panels (sides) and were not compared to the horizontal sections (tops) in any real way. That would be like comparing apples to oranges. Could you explain how this skews results if they aren’t being compared?

Good idea. I might 1st clay ½ of each horizontal section to see how different the beading would be. Then, later I could reseal this area to compare. I have a feeling that claying (even with mild clay) will pull/shave the top layer of the remaining sealant away; if in fact any is still there.

It’s really hard to tell at this point whether the beading I from protection and/or surface tension from being a new vehicle (hardly any surface degradation). From the pictures, the Malco beading seems to be the most round, small and tight throughout the entire horizontal surface

Thanks again (as always) for your support and wit. You rock! :2thumbs:

Thanks. You are correct on both thoughts. This car never is parked in the garage. The sides (because of gravity) bead much differently than the tops. I only had enough room (3 body panels) to test 6 products on the horizontals. Because I also had some Menzerna & 1Z, I thought I’d throw them in on the 8 possible vertical panels.

Great. I’ve been using it on other vehicles and I’ve received a lot of positive feedback from the owners. It also has a really enjoyable smell too.

The thanks will never end Jon! You’re a very knowledgeable person.

paintxpert said:WOW this guy should be getting overtime....Good work David. Cant wait to hear the results. Its hard to get a product to show protection after 4 months...at least in the North East, that has been my finding....This should prove interesting. Good Luck David.