David Fermani

Forza Auto Salon

See Page 5 of thread for 6 month observations

8-Way Paint Sealant Test - 2008 Chevy Malibu – Silver

I’m testing out 8 different paint sealants on my silver 2008 Chevy Malibu (company car). Below are the initial results after application of these products on various panels of the car. Because durability is the main/most important factor in the test, at this time I can only report a few different variances after initial application. There will be more date to follow in the months to come.

Prep of Vehicle:

Because this vehicle was a special order, it did not sit on the dealership lot. I requested that the dealer not prep or wash it in an effort to minimize marring and not introduce any silicones that could interfere with the application process. Unfortunately, the vehicle has not been washed yet and it was picked up 9-12-07 (see baked on bird crap).

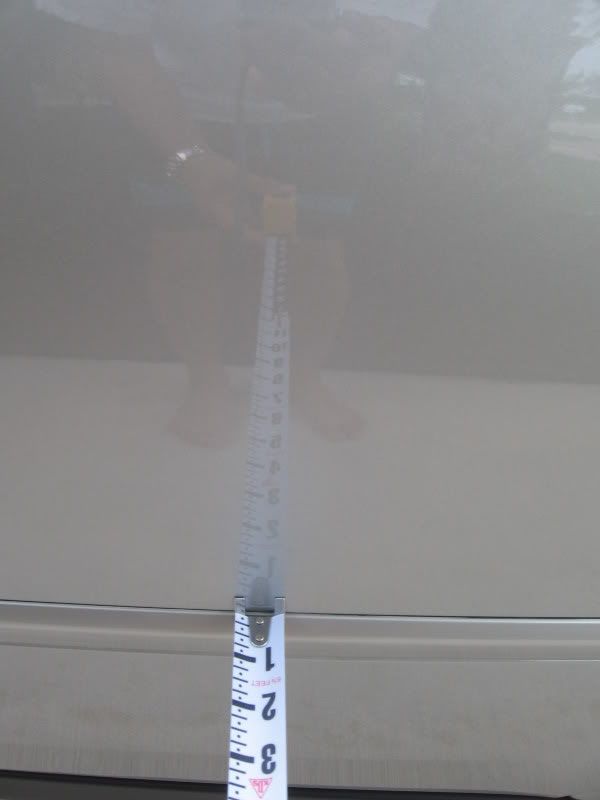

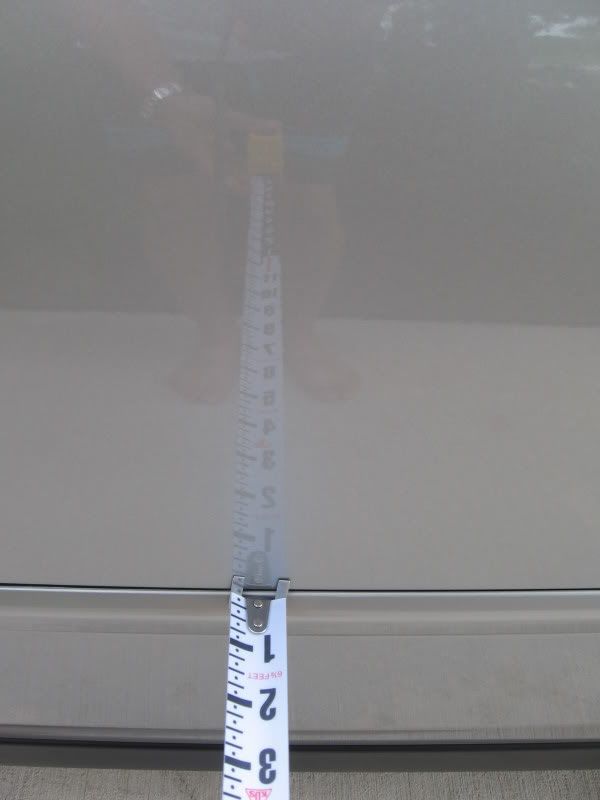

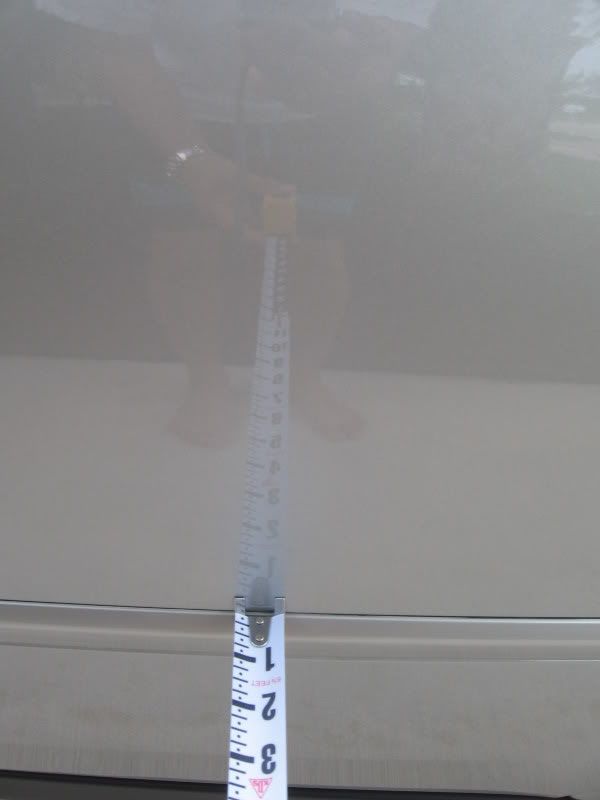

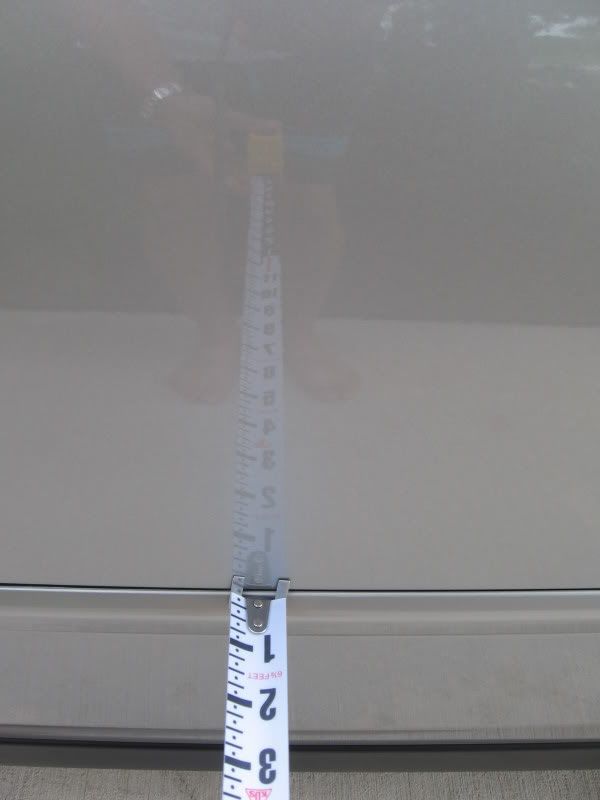

Beading within 1 week of delivery (no protection):

*Wash with Dawn dishwashing soap

*Blue Auto Magic Clay Magic with AM Body Shine – (see pic of contaminants on clay)

*2nd Dawn wash to remove Body Shine residue to avoid application disturbances

***Prior to the Dawn wash, vehicle beaded water. After the wash, there was no beading (see pics)***

After Dawn wash(no beading):

Here's the reason why you're suppose to clay a brand new car(especially one that's getting sealed):

Application of Sealant:

*1 coat of each sealant via foam applicator pad by hand

*Dry/haze for ~ 1 hour

*Wipe off / remove

*2 hours of sitting in 95 degree sun + 8 hours in garage to complete cross-linking of polymers

*2nd coat of sealant (10-11 hrs later)

*Dry/haze for 1 hour

*Wipe off / remove

*14 hours later observe results >>>

Testing process:

*** About 14 inches of the finish has been taped off down the center of the vehicle and no LSP was applied. 6 different sealants were applied on both sides of the bare finish to compare gloss and protection (beading). E.G. if the sealed side shows the same characteristics as the center of the panel = No Protection. I will do periodic inspections of the finish as well as examine and document the beading effect with pictures.

Paints Sealants Tested:

Zaino Z-2 PRO Show Car Polish

(applied to left side of hood and left fender)

*Ease of application = 1 out of 5. This was the most difficult sealant to apply out of the 8 I tested. I needed to reapply product to the applicator 3 times. Evaporates very fast and you can’t really tell if there’s product on the surface. It’s difficult to go over the protected area again because of the quick drying time. I’d imagine there’s a learning curve that needs to be figured out to master its application.

*Ease of removal = 5 out of 5. Because of the nature of the way this product is applied, it has very little haze and wipes off with total ease. A quick wipe down and you’re done.

Chemical Guys Jetseal 109 Paint Sealant

(applied to left rear door and right roof)

*Ease of application = 3 out of 5. Evaporates quickly and required 2 applications of product on applicator pad to coat the desired area. Goes on really thin and noticeable, but doesn’t spread real far. Would work a lot better if applied with a PC.

*Ease of removal = 3 out of 5. Didn’t wipe off as easy as possible, but didn’t require a lot of going over to insure the entire product was removed. Really thin and creates no dusting.

Malco Paint Sealant

(applied to left front door and left roof panel)

*Ease of application = 4 out of 5. Goes on milky smooth like a carnauba and has the ability to be rubbed over the same surface multiple times without skidding/catching.

*Ease of removal = 3 out of 5. Isn’t the hardest and isn’t the easiest to remove. Takes a couple of attempts to make sure the entire product is removed. Hazes nice, but a quick wipe won’t insure all is gone. I looked down the surface and noticed a little residual traces that needed correcting. Not a big deal. No streaking.

Mark V Products Paint Sealant

(applied to left side of trunk and left ¼ panel/surround)

*Ease of application = 4 out of 5. Goes on really smooth and stays wet. Blue in color and can easily be seen after applying.

*Ease of removal = 4 out of 5. Comes off really easy and the haze can easily be seen. No dusting or residue. A joy to work with. I put it on heavy both times and it came off really easy.

CPC Corp R-2000 Paint Sealant – contains DuPont ZONYL

(applied to left side of trunk and left ¼ panel/surround

*Ease of application = 2 out of 5. Very thin product and requires a liberal amount to coat the surface properly. Dries quickly and is easy to see surface coverage. Manufacture recommends using their Acid Rain Neutralizer prior to application, but after speaking with someone in their tech support, they just require that surface to be clean and contaminant free. They also recommend using the entire 2.25 oz bottle to the entire vehicle. Once the bottle is opened, it’s only supposed to be applied within 8 hours. Highly flammable and not to be applied to hot surfaces or in direct sunlight.

*Ease of removal = 4 out of 5. Comes off very easy, probably because it goes on so thin. There’s a tiny bit of dusting, but not enough to cause a problem. 1swipe of the surface and it’s removed.

1Z Einsett Glanz Sealant

(applied to right rear door)

*Ease of application= 4 out of 5. Goes on really nice and is very workable without quickly drying. purplish-pink in color and can be easily seen on the surface while appling. Goes on like a carnauba and is creamy in texture.

*Ease of removal = 4 out of 5. Wipes off easy and its haze is noticeable on the surface. No dusting. Wipes right off the 1st time.

Menzerna FMJ Paint Sealant

(applied to right front door)

Ease of application = 4 out of 5. Goes on nice and thin & can be worked several times over the surface without drying. Very nice to work with.

Ease of removal = 4 out of 5. Comes off very easy and has a thin haze which is easily noticeable.

Jeff Werkstatt Acrylic Jett

(applied to right side of hood and right fender)

*Ease of application = 5 out of 5. A little goes a long, long way. This product goes on easy, stays wet and can be worked over the surface multiple times without loss of spreadability. I’ve never used a product that goes on so easy.

*Ease of removal = 1 out of 5. It’s a major pain in the butt to remove this stuff. I had to literally scrub the surface to remove the streaks. I decided that I must have put on too much, so I applied just a tiny bit the 2nd time, but the results were the same.

Assumptions about the look of each product:

It was almost impossible to really notice any difference in looks between each product. Clarity/gloss/depth/reflection is all very, very close. There wasn't a single product that made the finish look better. Also, with the metallic flake finish this vehicle has, no product made the flake stand out or sparkle more or less the other. I'm sure there would be much greater differences with darker colors.

8-Way Paint Sealant Test - 2008 Chevy Malibu – Silver

I’m testing out 8 different paint sealants on my silver 2008 Chevy Malibu (company car). Below are the initial results after application of these products on various panels of the car. Because durability is the main/most important factor in the test, at this time I can only report a few different variances after initial application. There will be more date to follow in the months to come.

Prep of Vehicle:

Because this vehicle was a special order, it did not sit on the dealership lot. I requested that the dealer not prep or wash it in an effort to minimize marring and not introduce any silicones that could interfere with the application process. Unfortunately, the vehicle has not been washed yet and it was picked up 9-12-07 (see baked on bird crap).

Beading within 1 week of delivery (no protection):

*Wash with Dawn dishwashing soap

*Blue Auto Magic Clay Magic with AM Body Shine – (see pic of contaminants on clay)

*2nd Dawn wash to remove Body Shine residue to avoid application disturbances

***Prior to the Dawn wash, vehicle beaded water. After the wash, there was no beading (see pics)***

After Dawn wash(no beading):

Here's the reason why you're suppose to clay a brand new car(especially one that's getting sealed):

Application of Sealant:

*1 coat of each sealant via foam applicator pad by hand

*Dry/haze for ~ 1 hour

*Wipe off / remove

*2 hours of sitting in 95 degree sun + 8 hours in garage to complete cross-linking of polymers

*2nd coat of sealant (10-11 hrs later)

*Dry/haze for 1 hour

*Wipe off / remove

*14 hours later observe results >>>

Testing process:

*** About 14 inches of the finish has been taped off down the center of the vehicle and no LSP was applied. 6 different sealants were applied on both sides of the bare finish to compare gloss and protection (beading). E.G. if the sealed side shows the same characteristics as the center of the panel = No Protection. I will do periodic inspections of the finish as well as examine and document the beading effect with pictures.

Paints Sealants Tested:

Zaino Z-2 PRO Show Car Polish

(applied to left side of hood and left fender)

*Ease of application = 1 out of 5. This was the most difficult sealant to apply out of the 8 I tested. I needed to reapply product to the applicator 3 times. Evaporates very fast and you can’t really tell if there’s product on the surface. It’s difficult to go over the protected area again because of the quick drying time. I’d imagine there’s a learning curve that needs to be figured out to master its application.

*Ease of removal = 5 out of 5. Because of the nature of the way this product is applied, it has very little haze and wipes off with total ease. A quick wipe down and you’re done.

Chemical Guys Jetseal 109 Paint Sealant

(applied to left rear door and right roof)

*Ease of application = 3 out of 5. Evaporates quickly and required 2 applications of product on applicator pad to coat the desired area. Goes on really thin and noticeable, but doesn’t spread real far. Would work a lot better if applied with a PC.

*Ease of removal = 3 out of 5. Didn’t wipe off as easy as possible, but didn’t require a lot of going over to insure the entire product was removed. Really thin and creates no dusting.

Malco Paint Sealant

(applied to left front door and left roof panel)

*Ease of application = 4 out of 5. Goes on milky smooth like a carnauba and has the ability to be rubbed over the same surface multiple times without skidding/catching.

*Ease of removal = 3 out of 5. Isn’t the hardest and isn’t the easiest to remove. Takes a couple of attempts to make sure the entire product is removed. Hazes nice, but a quick wipe won’t insure all is gone. I looked down the surface and noticed a little residual traces that needed correcting. Not a big deal. No streaking.

Mark V Products Paint Sealant

(applied to left side of trunk and left ¼ panel/surround)

*Ease of application = 4 out of 5. Goes on really smooth and stays wet. Blue in color and can easily be seen after applying.

*Ease of removal = 4 out of 5. Comes off really easy and the haze can easily be seen. No dusting or residue. A joy to work with. I put it on heavy both times and it came off really easy.

CPC Corp R-2000 Paint Sealant – contains DuPont ZONYL

(applied to left side of trunk and left ¼ panel/surround

*Ease of application = 2 out of 5. Very thin product and requires a liberal amount to coat the surface properly. Dries quickly and is easy to see surface coverage. Manufacture recommends using their Acid Rain Neutralizer prior to application, but after speaking with someone in their tech support, they just require that surface to be clean and contaminant free. They also recommend using the entire 2.25 oz bottle to the entire vehicle. Once the bottle is opened, it’s only supposed to be applied within 8 hours. Highly flammable and not to be applied to hot surfaces or in direct sunlight.

*Ease of removal = 4 out of 5. Comes off very easy, probably because it goes on so thin. There’s a tiny bit of dusting, but not enough to cause a problem. 1swipe of the surface and it’s removed.

1Z Einsett Glanz Sealant

(applied to right rear door)

*Ease of application= 4 out of 5. Goes on really nice and is very workable without quickly drying. purplish-pink in color and can be easily seen on the surface while appling. Goes on like a carnauba and is creamy in texture.

*Ease of removal = 4 out of 5. Wipes off easy and its haze is noticeable on the surface. No dusting. Wipes right off the 1st time.

Menzerna FMJ Paint Sealant

(applied to right front door)

Ease of application = 4 out of 5. Goes on nice and thin & can be worked several times over the surface without drying. Very nice to work with.

Ease of removal = 4 out of 5. Comes off very easy and has a thin haze which is easily noticeable.

Jeff Werkstatt Acrylic Jett

(applied to right side of hood and right fender)

*Ease of application = 5 out of 5. A little goes a long, long way. This product goes on easy, stays wet and can be worked over the surface multiple times without loss of spreadability. I’ve never used a product that goes on so easy.

*Ease of removal = 1 out of 5. It’s a major pain in the butt to remove this stuff. I had to literally scrub the surface to remove the streaks. I decided that I must have put on too much, so I applied just a tiny bit the 2nd time, but the results were the same.

Assumptions about the look of each product:

It was almost impossible to really notice any difference in looks between each product. Clarity/gloss/depth/reflection is all very, very close. There wasn't a single product that made the finish look better. Also, with the metallic flake finish this vehicle has, no product made the flake stand out or sparkle more or less the other. I'm sure there would be much greater differences with darker colors.