David Fermani

Forza Auto Salon

This past weekend I had the absolute once in a lifetime pleasure of working on this extremely rare collectible car for a very distinguished client of mine. This vehicle was custom ordered directly from Porsche and is the only Carrera GT ever produced in this “Paint to Sample� Gulf Blue (for a mere $16,000 option). This color was made famous due to the Gulf Oil’s sponsorship if Porsche’s racing effort in the 1970’s. During that era all Gulf Oil sponsored Porsche racing cars were painted this color. This car is the very same color as Steve McQueen’s character’s 917 racing car in the movie LeMans. This vehicle is currently offered for immediate sale on E-BAY Motors for the reserved price of just $575,000. Here’s the link to the auction: eBay Motors: Porsche (item 160238764693 end time May-18-08 12:04:09 PDT)

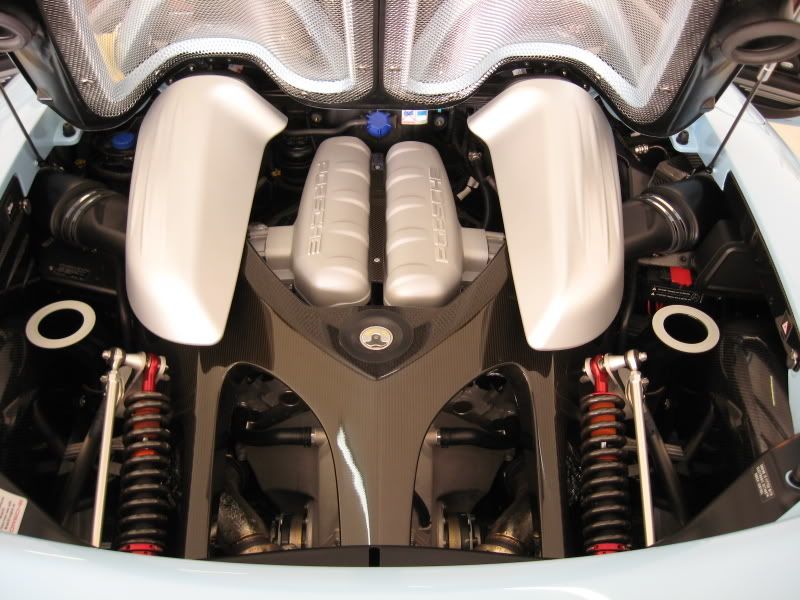

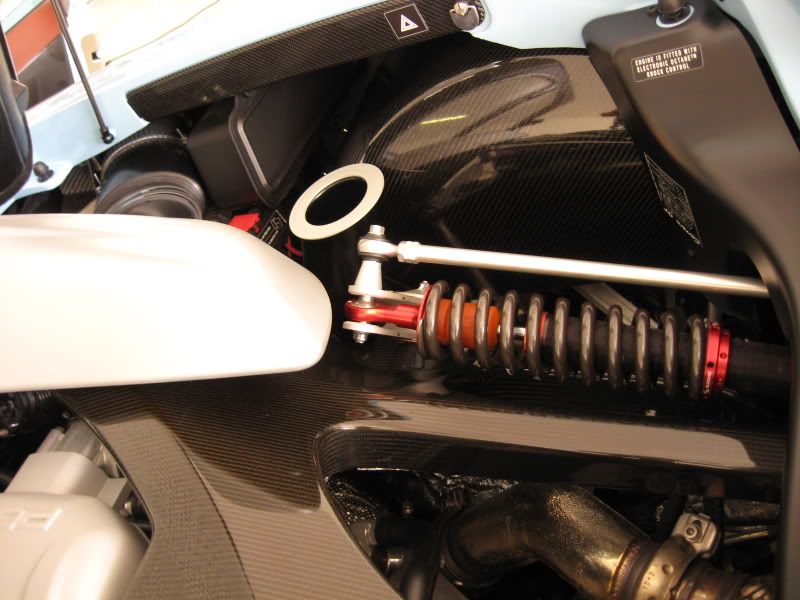

This mid-engine 2 seat roadster features a 605 hp 5.7-liter V10 engine, the 1st ceramic composite clutch used in a production car, and Porsche claims a top speed of 205 mph. The vehicle’s structure is constructed entirely out of Carbon Fiber and weighs in at approximately 3000 lbs. Right around 1000 Carrera GT’s were produced world wide, 600 of which were sold in the US market. This is the only vehicle in existence painted in Gulf Blue. It is also believed that approximately 50 or so vehicles have so far been destroyed, making this vehicle even more desirable.

Even though this car was considered to be in “like new� condition (only 599 miles!), I felt there was room for much needed improvement. Every possible single square inch was gently cleaned, polished and sealed over the course of my 17 hour treatment at the owner’s private lakefront airplane hanger just outside the prestigious city of Palm Beach. Working in this immaculately spacious facility allowed me to concentrate every effort into insuring the vehicle was as perfect as humanly possible. Working on this masterpiece was like a detailers dream come true.

Day 1:

I met with the owner and saw the vehicle for the 1st time early Saturday morning (around 7am). After pulling the vehicle outside, I set up all my gear and made up a fresh bucket of car wash soap. The vehicle was 1st power washed with my electric 1500 psi unit to remove any loose debris.

I then gently washed each section of the exterior with a healthy mixture of Auto Magic (AM) E-Z Sudds soap along with a my EDGE Grout ShMitt and regular HD GS. All wheels (including tires, wheel wells & barrels) where cleaned with a combination of brushes along with a heavy cut dilution (1 to 8) of AM Magnificent Wheel Cleaner.

After rinsing and drying, I then blew any remnants of water out of every crack & crevice with compressed air so that it wouldn’t interfere with the taping & buffing process.

I then thoroughly inspected the finish under full natural sunlight. Pretty much the entire vehicle suffered from factory originated buffer induced holograms. It’s amazing that such a well engineered and manufactured vehicle lacked in final paint appearance. This void really subtracted from the overall finishes gloss and depth.

I then pulled the vehicle inside, performed a complete walk around with the owner under twin 500 watt halogen lights and then proceeded to thoroughly clay, dry and re-inspect each panel again. During the clay process, I used cellophane to magnify the feeling of any remaining contaminants on the finish and re-clayed until the finish was 100% smooth. Having a completely contaminant free finish initially is key prior to any buffing and/or sealing of the finish. Products of choice were AM Blue Clay Magic & AM Body Shine lube.

I then carefully taped and covered every critical seam, edge & molding to prevent any unforeseen friction/overspray to these sensitive sections. Total prep time = 5 hours.

While inspecting the vehicle inside, I couldn’t help to notice some factory flaws.

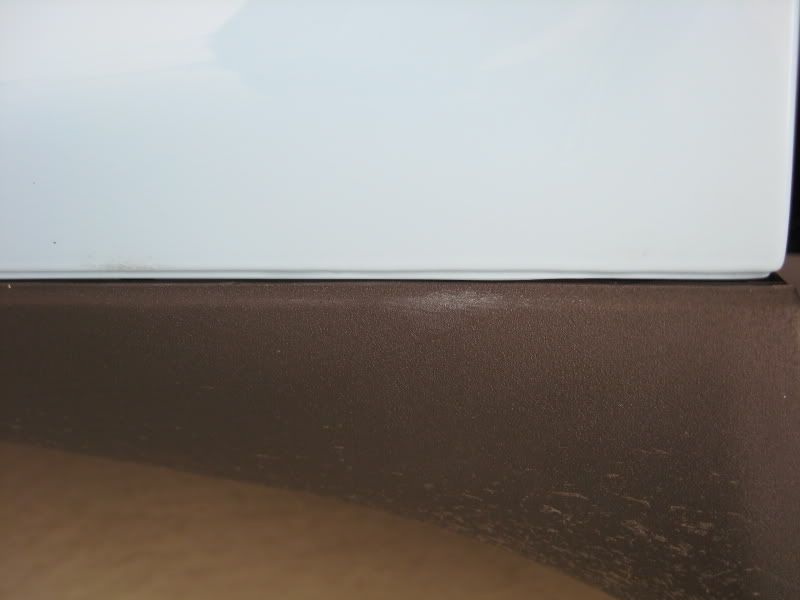

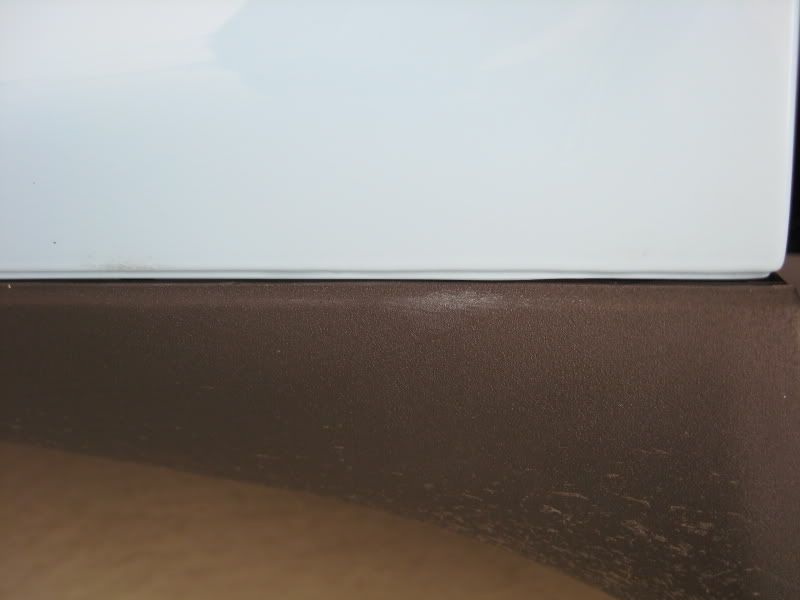

Compound/Transfer on Rocker Molding:

Compound in Door Jamb/Rocker Seam:

I 1st experimented with Menzerna 106FF with a white Lake Country 6.5 inch white CCS foam pad. While this combination made for a very deep gloss, it still didn’t allow the polish to cut through all of the sacrificial defects.

Test Panel:

Here’s after 106FF with White Foam Pad (room for improvement):

I then switched to a LC orange pad and this created the truest, cleanest and safest correction. As many of you know, it’s been discussed several times that Menzerna polishes can “act up� in non-factory settings. While buffing, I positioned a 5 foot cooling fan directly near each work area to reduce humidity to create a problem free work environment.

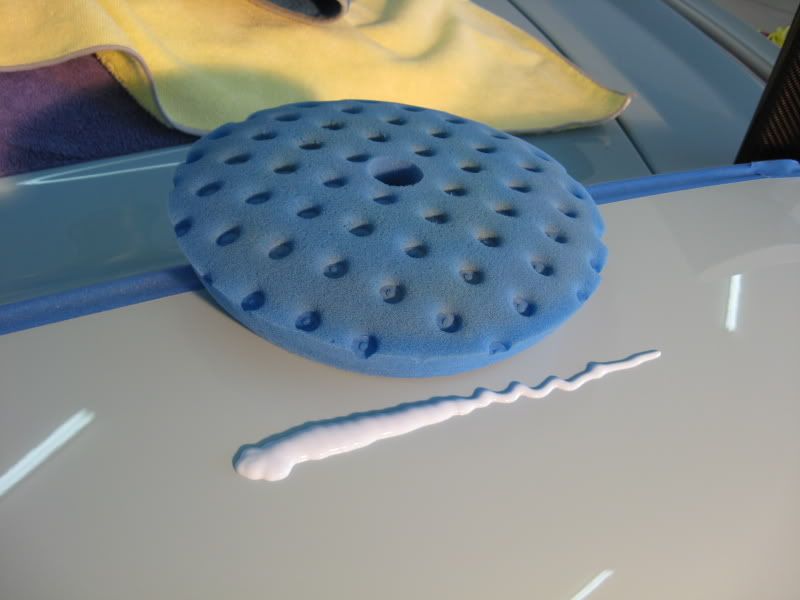

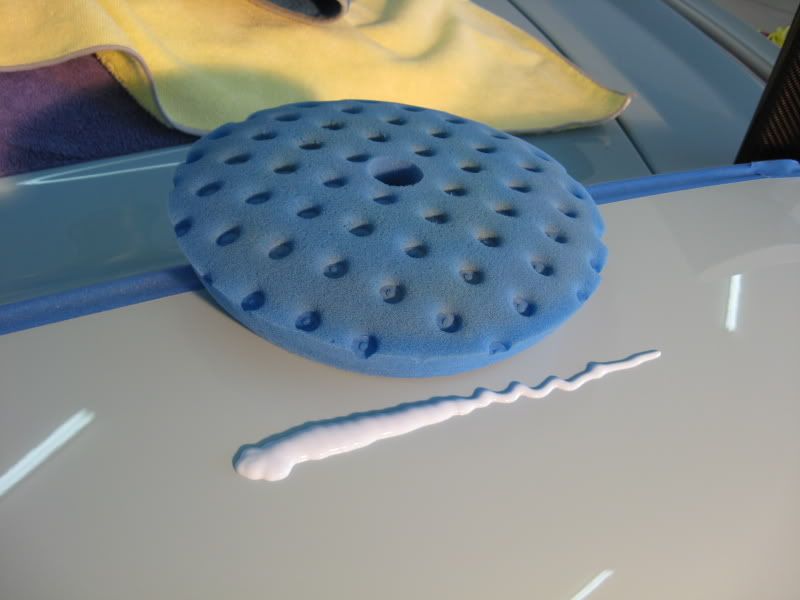

Here’s a shot of some Ultrafina applied to the panel just before buffing:

Rear Lid = Barely enough clearance for my buffer:

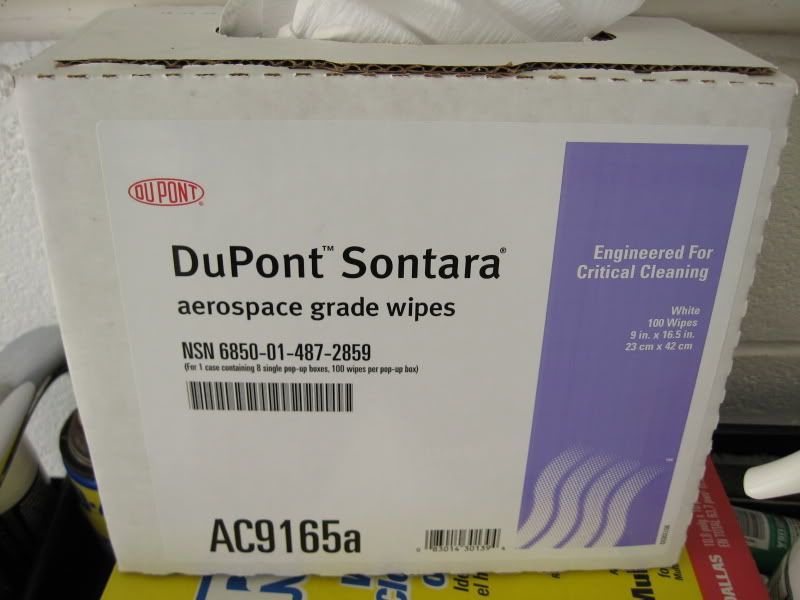

Prior to & after final finishing with 3M Ultrafina polish via a LC Blue pad, all polished surfaces were wiped down with 3M surface prep aerosol cleaner and a MF towel. Here’s a shot of the residual oils that get sprayed throughout the adjacent sections after buffing with Ultrafina:

This mid-engine 2 seat roadster features a 605 hp 5.7-liter V10 engine, the 1st ceramic composite clutch used in a production car, and Porsche claims a top speed of 205 mph. The vehicle’s structure is constructed entirely out of Carbon Fiber and weighs in at approximately 3000 lbs. Right around 1000 Carrera GT’s were produced world wide, 600 of which were sold in the US market. This is the only vehicle in existence painted in Gulf Blue. It is also believed that approximately 50 or so vehicles have so far been destroyed, making this vehicle even more desirable.

Even though this car was considered to be in “like new� condition (only 599 miles!), I felt there was room for much needed improvement. Every possible single square inch was gently cleaned, polished and sealed over the course of my 17 hour treatment at the owner’s private lakefront airplane hanger just outside the prestigious city of Palm Beach. Working in this immaculately spacious facility allowed me to concentrate every effort into insuring the vehicle was as perfect as humanly possible. Working on this masterpiece was like a detailers dream come true.

Day 1:

I met with the owner and saw the vehicle for the 1st time early Saturday morning (around 7am). After pulling the vehicle outside, I set up all my gear and made up a fresh bucket of car wash soap. The vehicle was 1st power washed with my electric 1500 psi unit to remove any loose debris.

I then gently washed each section of the exterior with a healthy mixture of Auto Magic (AM) E-Z Sudds soap along with a my EDGE Grout ShMitt and regular HD GS. All wheels (including tires, wheel wells & barrels) where cleaned with a combination of brushes along with a heavy cut dilution (1 to 8) of AM Magnificent Wheel Cleaner.

After rinsing and drying, I then blew any remnants of water out of every crack & crevice with compressed air so that it wouldn’t interfere with the taping & buffing process.

I then thoroughly inspected the finish under full natural sunlight. Pretty much the entire vehicle suffered from factory originated buffer induced holograms. It’s amazing that such a well engineered and manufactured vehicle lacked in final paint appearance. This void really subtracted from the overall finishes gloss and depth.

I then pulled the vehicle inside, performed a complete walk around with the owner under twin 500 watt halogen lights and then proceeded to thoroughly clay, dry and re-inspect each panel again. During the clay process, I used cellophane to magnify the feeling of any remaining contaminants on the finish and re-clayed until the finish was 100% smooth. Having a completely contaminant free finish initially is key prior to any buffing and/or sealing of the finish. Products of choice were AM Blue Clay Magic & AM Body Shine lube.

I then carefully taped and covered every critical seam, edge & molding to prevent any unforeseen friction/overspray to these sensitive sections. Total prep time = 5 hours.

While inspecting the vehicle inside, I couldn’t help to notice some factory flaws.

Compound/Transfer on Rocker Molding:

Compound in Door Jamb/Rocker Seam:

I 1st experimented with Menzerna 106FF with a white Lake Country 6.5 inch white CCS foam pad. While this combination made for a very deep gloss, it still didn’t allow the polish to cut through all of the sacrificial defects.

Test Panel:

Here’s after 106FF with White Foam Pad (room for improvement):

I then switched to a LC orange pad and this created the truest, cleanest and safest correction. As many of you know, it’s been discussed several times that Menzerna polishes can “act up� in non-factory settings. While buffing, I positioned a 5 foot cooling fan directly near each work area to reduce humidity to create a problem free work environment.

Here’s a shot of some Ultrafina applied to the panel just before buffing:

Rear Lid = Barely enough clearance for my buffer:

Prior to & after final finishing with 3M Ultrafina polish via a LC Blue pad, all polished surfaces were wiped down with 3M surface prep aerosol cleaner and a MF towel. Here’s a shot of the residual oils that get sprayed throughout the adjacent sections after buffing with Ultrafina: