RaysWay

Autopia Specialist

Something to consider if you are going to use a small diameter pad on a rotary...

A rotary gets the majority of its polishing power from edge speed. The smaller you make the pad, the less edge speed you have... A 3-inch pad will travel 1/2 the speed of a 6-inch pad at the same RPM. A 2-inch pad will travel 1/3 the speed at the same RPM and a 1-inch pad will travel 1/6 the speed at the same RPM.

When designing the Nano - a polisher built from the ground up for spot correction - this was a primary consideration. The end result is a tool that will run at 5000 RPM at max speed. This sounds like a lot, but keep in mind that the pad diameter in rotary mode is 1.2 inches (approx.).

So a 1.2-inch pad at 5000 RPM is the same edge speed as a 6-inch pad at 1000 RPM. The smaller the pad, the higher the RPM needs to be on a rotary to maintain polishing power.

On a random orbital polisher, the opposite is true. Most of the pad speed comes from the orbital action. The beauty of an orbital polisher is that orbital speed is the same at any point on the pad.

Just some things to consider

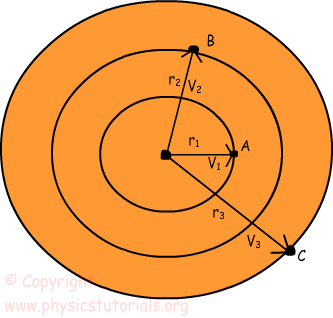

Great points! I'm having flashbacks to physics class. This is called Tangential Speed (where velocity changes depending on the distance from the center of a rotation).

[h=4]Formula:[/h] V[SUB]t[/SUB] = r ω

Where, V[SUB]t[/SUB] - Tangential Velocity (m/s)

r - Radius

ω - Angular Velocity (rad/s)

Anyone can use a few online calculators to find the Tangential Velocity with their pad size and speed setting. I just ran a few calculations and even with a small pad, you can get some very high tangential velocity numbers; which is why detailers should still be very careful with these small polishers (and would explain how I ended up burning through an edge with a PE8 and a 2 inch pad).

p.s. luckily the burn through was in the engine bay of my personal car.