Since the weather has been so nice here in New England over the past couple weeks, business has been booming at Unique Car Care! It seems like everyone is looking to get their cars on the road all at once after being stored away all winter long. Just this week alone, I had five cars in the shop for full front-end coverage clear bra installs. As you can see, the shop is stuffed with cars, so I might have to look into getting a bigger shop soon!

The road conditions around here in MA are pretty horrible and the only way to ensure your vehicles paint is protected against stone chips, road debris, and other foreign objects is to have paint protection film (aka PPF or clear bra) installed to all high-impact areas of the paint surface.

I have been installing paint protection film for a long time now and the market has changed quite a bit since ‘clear bra’ was introduced many years ago. The older films were known for having excessive orange peel (texture), a cloudy appearance, visual defects and known to turn yellow and discolor over time. Since things normally get better over time, the clear film market has changed quite a bit (for the better!). Nowadays, most of the premium brand films on the market have a clearcoat topcoat which results in better clarity, UV protection and a better appearance than the previous generation films.

It can get pretty confusing when trying to choose what brand of film to use, which is why we are constantly testing different films to ensure that we are using only the best films available on the market. We have been experimenting with XPEL’s new Ultimate Paint Protection Film lately and are totally impressed by it. Not only does it shrug off contaminants that would normally stain or damage conventional films, but it has a clear coat that contains elastomeric polymers that " self heal" over time, eliminating swirl marks and other minor blemishes without the need of any special care.

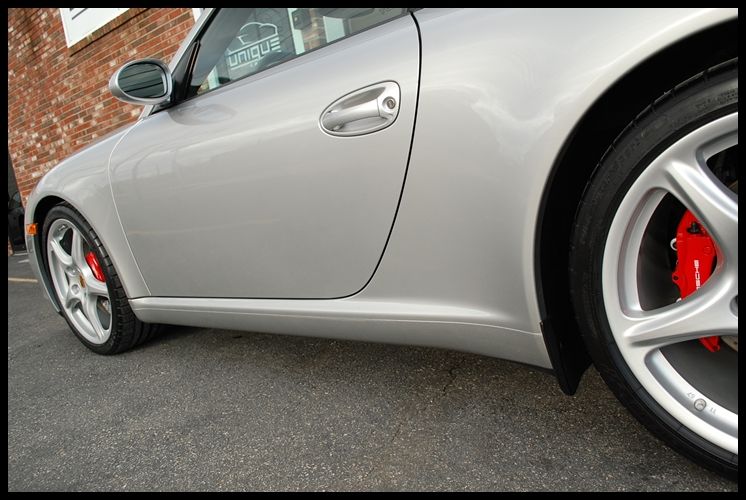

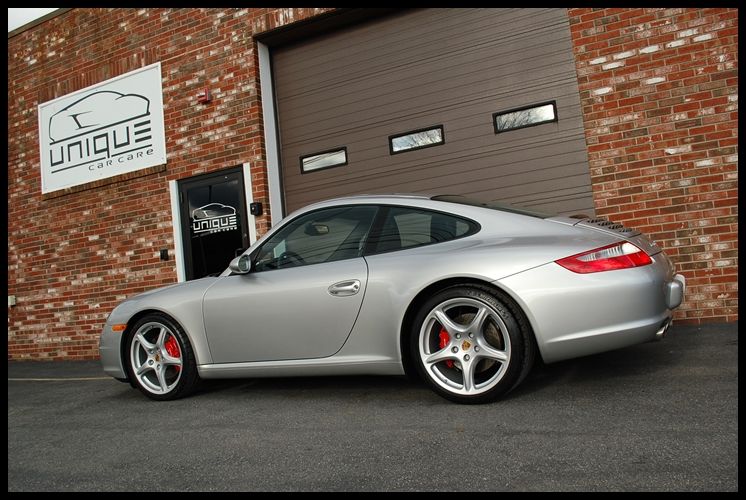

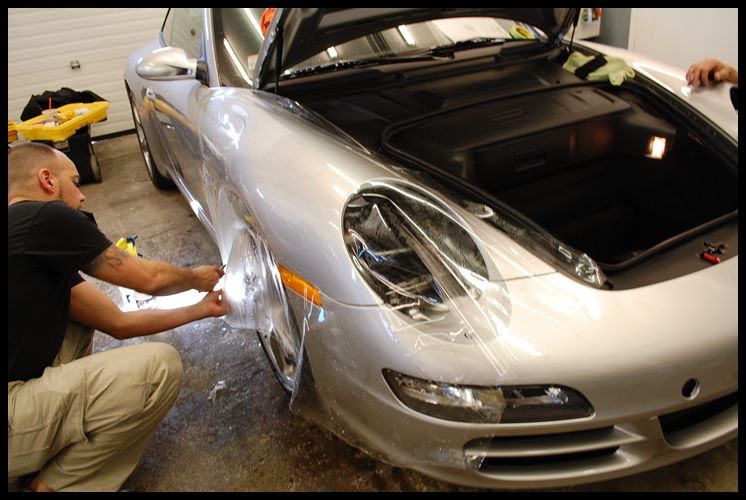

This Carrera S was in for a custom clear bra install to protect the paint against stone chips and keep the factory paint looking good for years to come. The owner had just purchased the car and wanted all high-impact areas to be wrapped in paint protection film, including the complete hood, complete fenders, complete front bumper, side mirrors, headlights, rocker panels, splash guards and rear mud flaps.

Instead of using a precut kit like most installers do, we perform a fully custom install using bulk film. This allows us to wrap all panel edges for maximum coverage and a clean install without having unnecessary seams. Precut kits are computer generated for specific models and have lots of large openings around the park distance sensors, reflectors, etc… By doing a custom install, any openings are trimmed as close as possible, which really makes a huge difference in the overall appearance when finished.

To start, Bryan and I washed the exterior and stripped any protection that may have been applied to the surface to ensure there was a perfect foundation for the film to adhere to. In addition, all areas being covered in film were clayed to remove any bonded contaminants.

After washing the exterior, we wiped all door, hood and trunk jambs, then dried all exterior surfaces and blew out all cracks & crevices with air to ensure every bit of dirt was removed which could possibly interfere with the film install later.

As you can see in the picture below, the factory splash guards on the rear quarter panels were starting to turn yellow and had to go.

I carefully removed the splash guards by using a heat gun to loosen up the adhesive. We were planning on adding custom pieces with additional coverage to this high-impact area during the install.

Next up was to polish any areas being covered in film to ensure the paint was as perfect as possible before the install. Since this car isn’t brand new, there were a few existing stone chips that I repaired using Dr Colorchip kit after the polishing was complete.

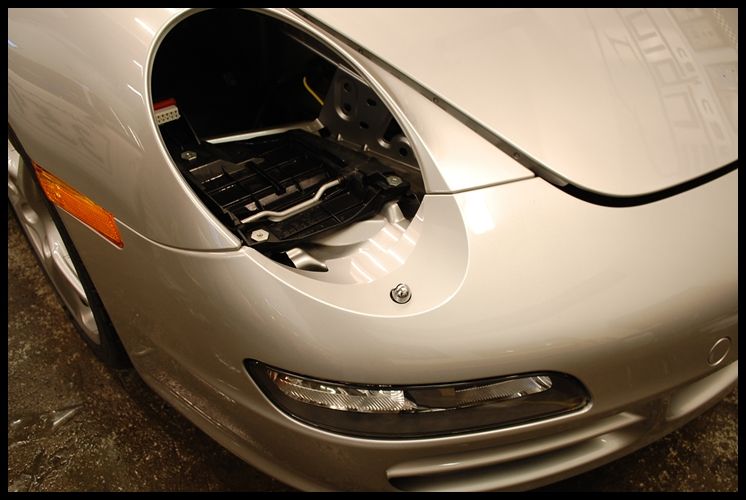

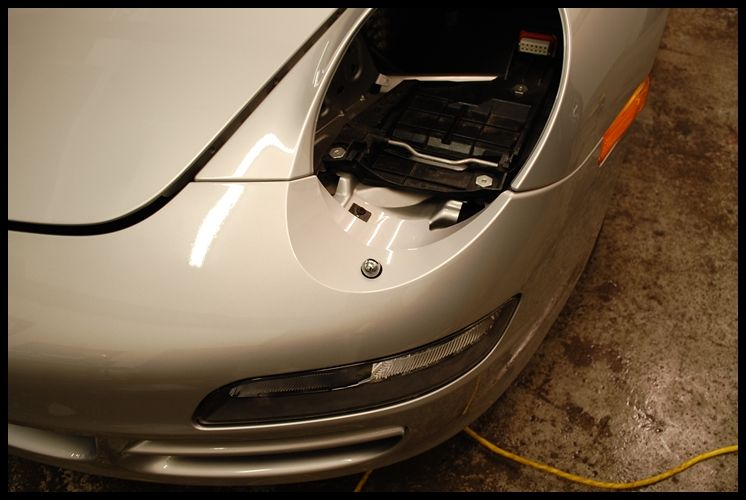

The Porsche hood emblem and headlights were removed in order to fully wrap the film behind and avoid as many visible seams as possible.

After the car was fully prepped, Joe got to work laying down the drivers side fender.

The areas inside the wheel wells were also fully wrapped to protect these critical areas from stone rash.

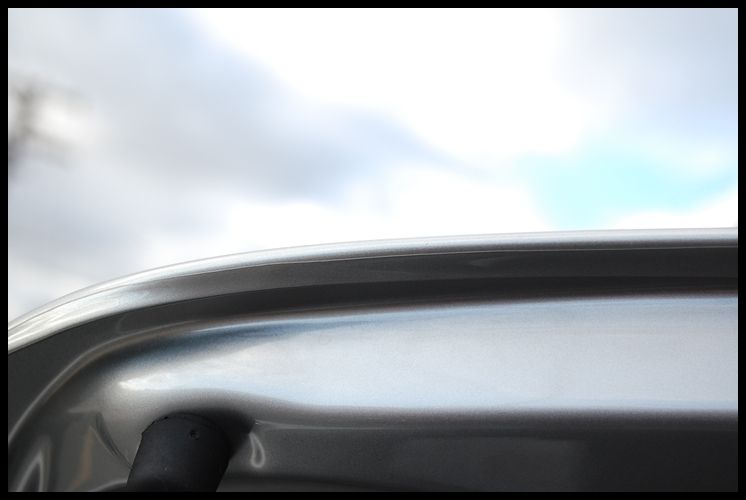

All edges are trimmed a little long so they can be completely wrapped over. This makes for a much cleaner install, gives added coverage and results in a virtually seamless install.

All headlight openings were fully wrapped as well.

Joe working on the passenger side fender…

Headlight openings wrapped…

Here’s Joe laying down the film for the hood and making funny faces pointing at his reflection .