Adams posted some good information on their product. They made a good point on one of their videos on why they have the word ceramic in their name. They took their ceramic coating and added graphene oxide to the formula. I am sure SPS and Ethos are doing something similar. It then becomes another version of a ceramic coating (ie: SiO2, TiO2, SIC, etc..). This was mentioned on the recent Obsessed Garage podcast as well dated 7-31-2020 towards the end about the blender B&B and adding graphene oxide to the ceramic fomula.

Why is Graphene still called a Ceramic Coating?

Graphene alone will not form a coating. Period. Graphene is a flat non-reactive plane, it will not form a bond with other things.

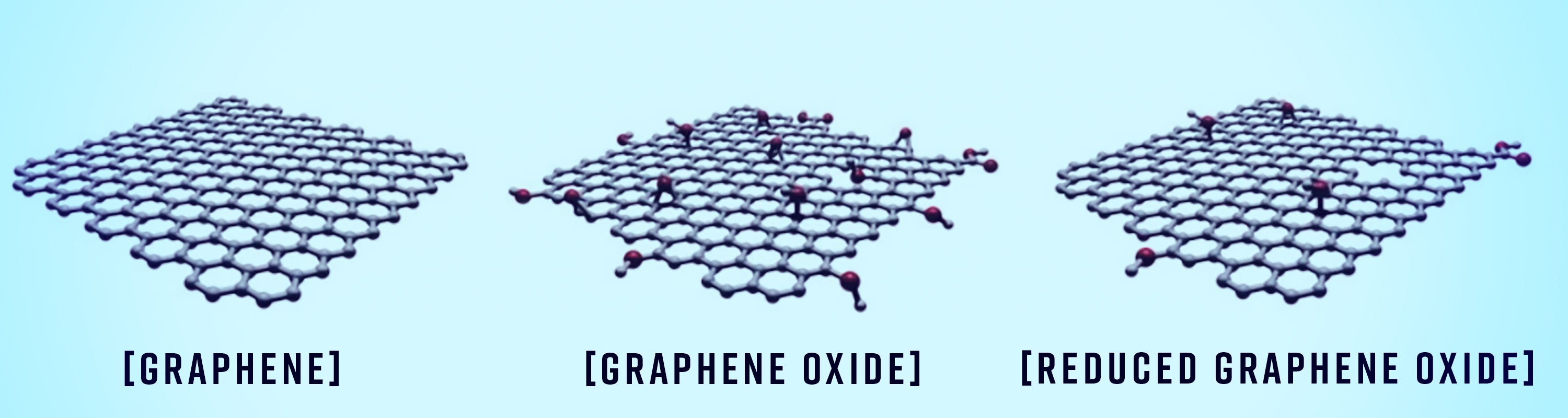

Graphene coatings are coatings with graphene molecules grafted onto the ceramic backbone. If you think of the graphic of the graphene oxide, the tails you see sticking up are what is grafted onto the ceramic molecule. The Ceramic molecule bonds with the car, and the graphene portion of the molecule is on top, forming the surface of the coating.

What`s The Difference Between Graphene And Traditional Ceramic Coatings?

Adam’s Graphene Ceramic Coatings

What are they and Why are they different?

Description:

In the simplest terms, Adam’s Graphene Ceramic Coating™ and Adam’s Graphene Ceramic Spray Coating™ are best described as evolutions on “traditional” ceramic coating technologies – the term traditional, as of this writing, referring to currently marketed ceramic coating offerings comprised of primarily quartz (SiO2), metal-oxides like titanium-dioxide (TiO2), silicon-carbide (SiC) and many others.

The R&D Process:

When we began formulating our Graphene Ceramic Coatings, we were seeking to improve upon the physical characteristics of our own ceramic coating offerings by providing them with additional hydrophobicity, chemical durability, scratch and mar resistance, gloss, slickness, and ease of application. We were interested in consolidating feedback into advancements in our coating technologies that would yield an even better experience for our customers.

What we determined was that the next frontier was likely to be utilizing technologies around graphene and incorporating this tech into our coatings and process.

To get very technical for a moment, what we’ve developed is a ceramic coating that has been modified via a reduced graphene-oxide (RGO). Graphene, a monolayer of graphite, is able to be oxidatively processed into graphene-oxide (GO) which makes the material vastly easier to process and formulate around. We can then combine this technology with some of the more traditional ceramic coating technologies to further retrofit them with additional properties while utilizing the ceramic coating’s ability to bond this matrix to the surface.

Figure 1 – Example of a Graphene-Oxide Matrix.

What we saw in quantitative and qualitative testing, in and out of the lab, was dramatically improved hydrophobic character, increased gloss, higher tensile strength yielding more scratch and mar resistance, and further improved resistivity to water spot etching and detergent washes – often taking in the hundreds of traditional car washes or even thousands of scrubs on our Elcometer Abrasion-Washability tester – See Figure 2.

Figure 2 – Adam’s Graphene Ceramic Coating after 5000 back-and-forth scrubs with a sponge exerting 500g of pressure and a 5% Dawn Ultra Dish Soap solution.

Hydrophobicity and its Relation to the Self-Cleaning Effect:

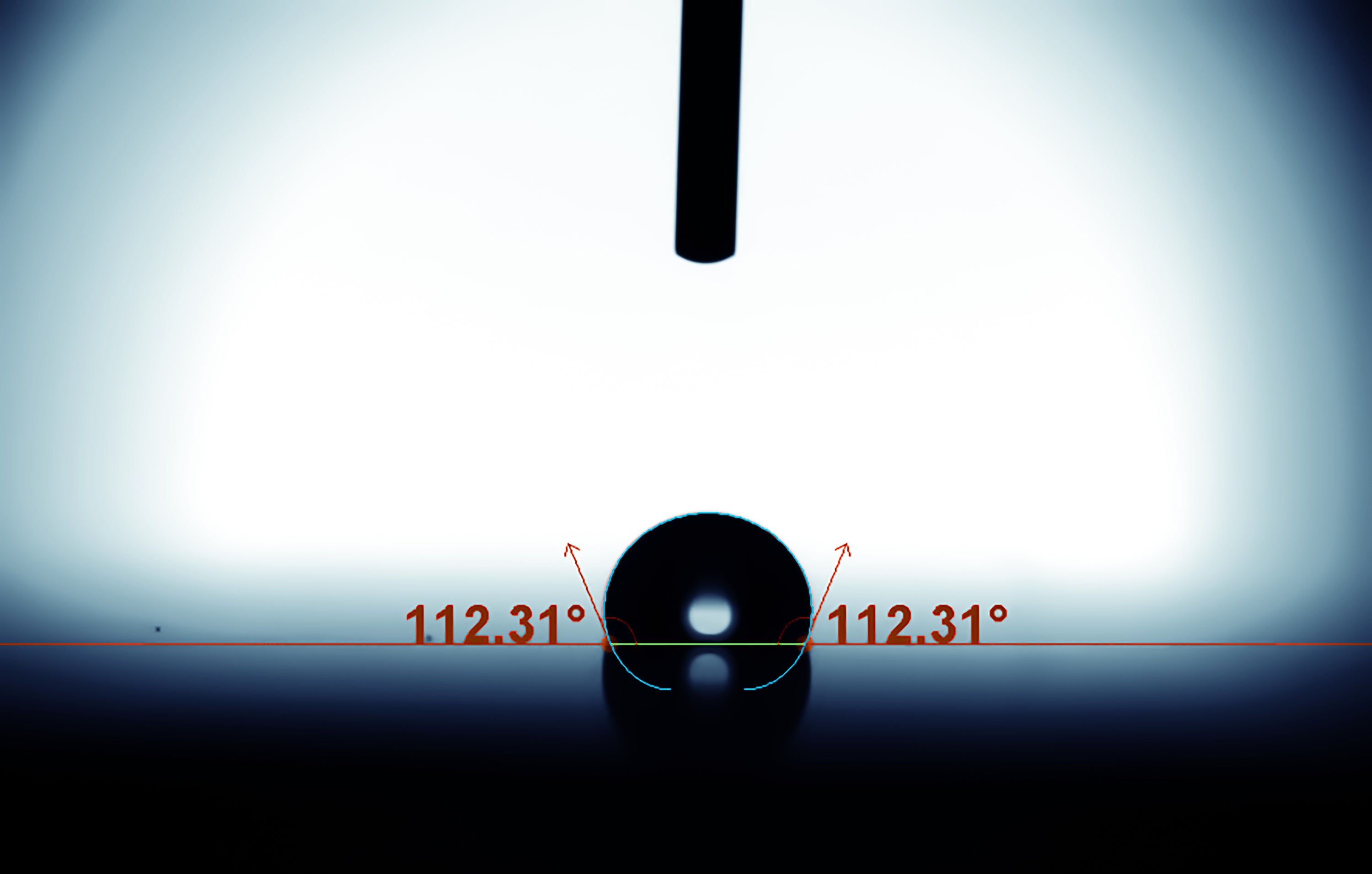

The improved hydrophobic character can best be described as a dynamic hydrophobicity. That is to say the contact angle was improved, but only marginally, but the sliding angle of the coating was dramatically lowered – that is the degree of tilt was found to be much less to get movement of water. This has huge ramifications on the effectiveness of the Lotus-Leaf Type “self-cleaning effect” offered by the coating, a primary attribute. The water will be observed to get off the surface much more dramatically than what’s seen on our current coating offerings.

Figure 3 – Adam’s Graphene Ceramic Coating contact angle with Deionized Water.

Compare & Contrast:

The application of Adam’s Graphene Ceramic Coating™ and Adam’s Graphene Ceramic Spray Coating™ are similar to what you’d expect from our current ceramic coating offerings, with a few key differences. An individual would find that the graphene offerings tend to cure more rapidly, so it some ways it may be found to be less user friendly – particularly in hot and humid climates which will accelerate the cure as well. However, the graphene offerings will also be found to be more highly slick and produce a higher level of gloss as the coating film is thicker due to a higher overall activity level compared to the quartz coatings – some of our highest actives coatings yet! Despite the higher activity, individuals will be surprised to note that the graphene coatings don’t have as harsh of an odor as the quartz coatings too.

One special characteristic we found in development of the graphene coatings were that they have a strong affinity for practically any external automotive surface. We’ve presented the Adam’s Graphene Ceramic Coating™ and Adam’s Graphene Ceramic Spray Coating™ as multi-surface coatings because they truly were appropriate for all manner of substrates be it paint, wheels, plastic trim, chrome, glass, rubber or metal. This provides additional ease of use to the end user because they are able to coat more surfaces utilizing a single bottle.

Maintenance:

Maintenance for the two types of coating technologies is very similar and the use of SiO2 based protection is still perfectly valid and acceptable as the Adam’s Graphene Ceramic Coating™ and Adam’s Graphene Ceramic Spray Coating™ still contain SiO2 based ingredients and will interact well to bolster and maintain the finish produced by the coatings.

Adam’s UV Ceramic Glow Technology™:

Thankfully, we were also able to formulate the coatings such that all Adam’s Polishes’ offerings of ceramic coatings have our patent-pending UV Ceramic Glow Technology™ which aids in the application of the coatings and allows visualization of the film post cure to ensure high spots are leveled properly and all surface area is properly coated.

Figure 4 – Demonstrations of UV Ceramic Glow Technology™.

Summary:

Again, it’s best to view Adam’s Graphene Ceramic Coating™ and Adam’s Graphene Ceramic Spray Coating™ as a necessary evolutionary step to ceramic coating technologies and not as simply a “carbon coating”. This is a reduced graphene-oxide system and it’s intended to retrofit traditional quartz-based ceramic coatings with additional functionality and improved physical characteristics.