Todd@RUPES

Just a regular guy

How a Backing Plate Design Affects Rotary Polishing.

A common question that I get asked is what is the best rotary backing plate for a rotary polisher?

Ultimately the best choice is the one that feels most comfortable to you. If you are comfortable with the way your rotary polisher feels in your hands then you will be able to polish to 100% of your potential. At Autopia-CarCare we sell a number of different brands, types, and sizes of backing plates.

While you want a backing plate that feels comfortable, there are performance differences in the way a backing plate will react. I personally keep three different backing plates (in different sizes) in my polishing bag, each used for specific reasons.

How Backing Plate Design Affects Polishing.

Height

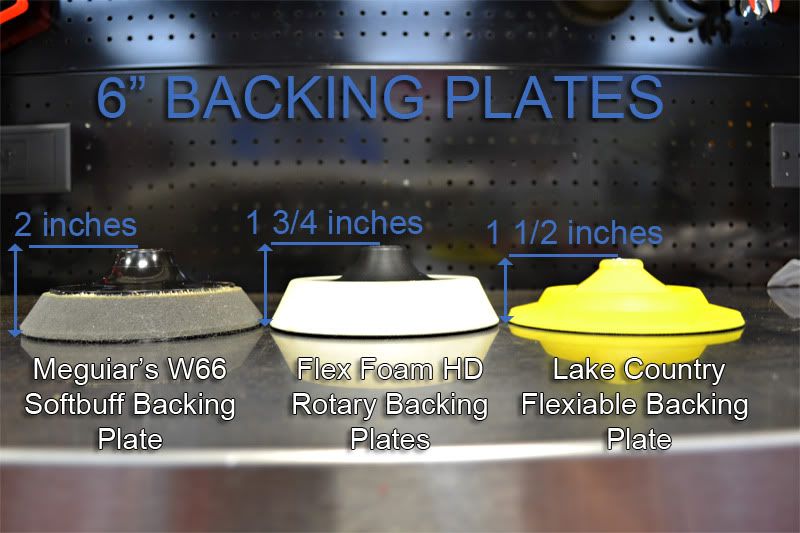

The three 6 inch rotary backing plates I have chosen to highlight each have a different height where the thread mounts to the spindle. The shortest, the Lake Country Flexible Backing Plate measures 1.5 inches tall, the Flex Foam HD Backing Plate measures 1.75 inches tall, and the Meguair's Softbuff W66 Backing Plate is 2 inches tall.

In most situations the height will not make a big difference. Remembering that most foam pads measure between .8275 to 1.25 inches thick, the added height of a backing black can reduce clearance when polishing tight areas such as under a spoiler or around a mirror for example. The Lake Country Flexible Backing Plate, by function of it's low height, will generally allow for the most clearance.

Backing Plate Flexibility

The reason I choose to highlight the three different backing plates in this article that I did (besides the fact that these are the three I use the most) is because each have a very density of foam. The more that the polishing surface contours to the surface being polished, the less aggressive it will become. Because most panels are not laser level (in fact most panels are contoured, often with complex curves) uses a firm backing plate in combination with a firm disc will yield an aggressive result.

A softer foam will rob the polishing surface of some energy as the backing plate foam (as well as the polishing pad foam) compresses and expands over the changes in paint altitude. For the most aggressive cut and the highest amount of leveling potential use a backing plate that is firm. For better control and less cut (and a more accurate finish on contoured surfaces) use a softer backing plate.

The Lake Country Flexible Backing Plate

The Lake Country Flexible Backing Plate is a low-profile design that is fairly stiff will remaining flexible at the outer edge. Of the backing plates in this article the Lake Country Flexible Backing Plate is going to offer the most leveling ability and the greatest clear.

When pushed onto the edge of a '57 Chevy, the orange foam compresses and rolls under. There is almost no bending of the the backing plate.

The Meguiar's W66 Softbuff Rotary Backing Plate

The Meguiar's W66 Softbuff Rotary Backing Plate is the tallest and softest of the backing plates featured in this article. The soft foam compresses easily but rebounds quickly. Just a little pressure between my thumb and finger pushes the foam in.

This makes the Meguiar's W66 ideal for polishing complex curves (think the hips of a Porsche 911) with ease, ensuring the the pad does not fold over and applies much more even pressure across contoured panels. The ability of the soft backing plate to transfer rotational movement (horizontal plane movement) for vertical plane movement (compression and extension of the foam as it conforms to contoured body panels) reduces the total amount of leveling ability of the pad it is used with but also reduces the rotaries tendency to steer. Since some energy is lost in the transition, the pad will not drive the rotary across the paint with as much vigor as a stiff pad which makes it ideal for beginners as well.

When pushed into the same curve as the Lake Country Flexible Backing Plate, the W66 keeps the pad edge from rolling under (hard to see) and keeps much more even contact with the paint's surface.

The Flex Foam HD Backing Plate

The Flex Foam HD Backing Plate is a medium height, medium density backing plate that is in between the others in terms of stiffness. It is an idea backing plate for most situations as it can still offers flexibility to polish most contours without rolling the pad over or losing control, yet remains stiff enough for idea polishing action. It is not as aggressive as the Lake Country Flexible Backing Plate, nor quite as easy to control as the Meguiar's W66. It took a fair amount more pressure between my finger and thumb to compress the backing plate.

Pressed against curve of the '57 Chevy revealed that the backing plate fit right in between the other two backing plates.

Choosing the right backing plate for you.

Ultimately there is no right or wrong answer. Find the backing plate that feels the most comfortable to you. I personally have been using the Flex Foam HD for a while now and love it's balance. I still keep the Lake Country near-by for times when I need to remove serious paint defects and wet sanding marks. I also keep the Meguiar's W66 in my bag for extremely curved or convex body panels, or when showing a user how to use a rotary.