Tru_Shine

New member

Wow! I wanted a Festool but now i'm kinda leaning to that makita BO6040

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

JuneBug said:Now this is why I read threads here, great info and civil discussion..

WhyteWizard said:Your illustrations don't take into account the way the different machines achieve forced rotation. I'd agree if they both got there the same way, but when the outside edge of the pad is moving with the direction of movement there is more net movement at any give rpm. One direction, with forced rotation achieved by planetary gears adds movement while forced movement by interfacing with the backing plate adds less. Put them side by side and you'll see exactly what I'm talking about. The outside edge on the flex doesn't make full circles.

All this being said, I have no doubt other detailers are getting good, even great results using methods and materials different from mine. I've seen their work, (Hey Barry, Kevin, Eric etc.) So, for me, what this is about is just letting people know what I've figured out and to check my work and to learn from people who's experience is different from mine.

Robert

The orbit on the flex accounts for 261888 mm of travel per minute at the center but uses part of that travel to force the rotation, while the orbits on the Makita account for 100166 mm of travel per minute and go in the direction of the rotation which is forced by the use of planetary gears.

The rpss of the Makita accounts for 315570 mm of travel while the rpms of the Flex accounts for 226080 mm of travel.

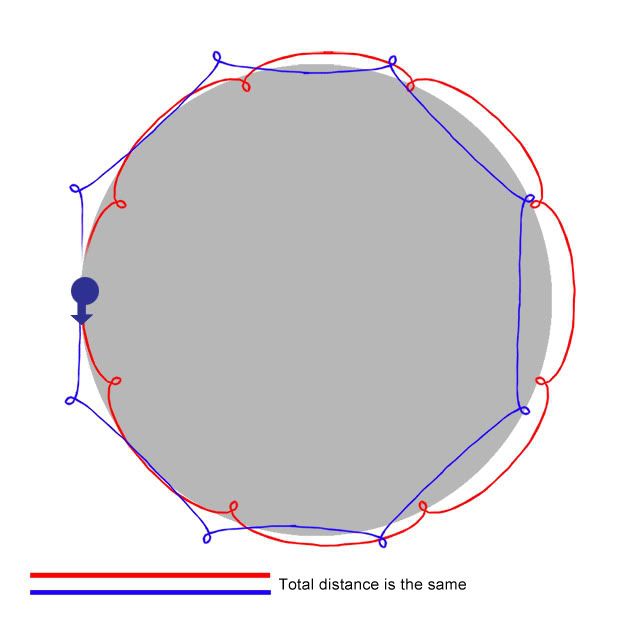

The Makita loses in number of orbits by 4100, but those orbits go in the direction of the spin, which results in the edge of the pad traveling in a curlicue pattern.

The spin with the Flex is, again achieved by interfacing the pad with the housing and results in the edge of the pad traveling in a scalloped pattern, with the travel coming to a stop at the edge directly in line with the spindle and the housing at when the two are closest.

The Makita creates a lot more movement between the pad and the paint.

The proof is in the heat generated when the two are run side by side with pad, pressure, product and paint held constant. The result was/is the Makita by a good margin.

The difference is that the two motions orbit and rotation are added together with the Makita but one contributes to the other, rotation drives - therefore subtracts - on the Flex.

WCD said:Festool 6" Sander ETS150/5

Is this the model? There is one on CL for 239 with low hours and I need this or the Flex.

Thanks for those that know, Rob

Accumulator said:Any ideas regarding how the planetary gear system of the Makita would hold up to applied pressure?

I'm merely curious; I don't want to overemphasize applying pressure, and IMO applying too much pressure is likely to lead to issues with the Flex....but with all the Flex-user talk about backing plate-to-housing contact/lubing the felt ring/ etc. I get the impression that some people do lean on it pretty hard.

JuneBug said:Damn it - now I want a BO6040, well, my 51st B-day is only 4 months away and ....

JuneBug said:Well, the wife and my mom got together and bought a nice electric power washer from Northern Tool this Saturday, and with the little air compressor I got from work bonus points - things are looking up. It takes time to get your shop just the way you want it, and even more time to become good at the tools/products/technique - but it's an interesting ride!