imported_gusbubba

New member

I've been using the 6.5" LC constant pressure pads but have recently thought of stepping up to a 7.5 or higher for better reach under mirrors and such.

I have been keeping it in the same speed range as you mentioned to good effect. This machine's a good bit more powerful than the PC , and you're right , it takes a bit of patience and re-learning with combos.

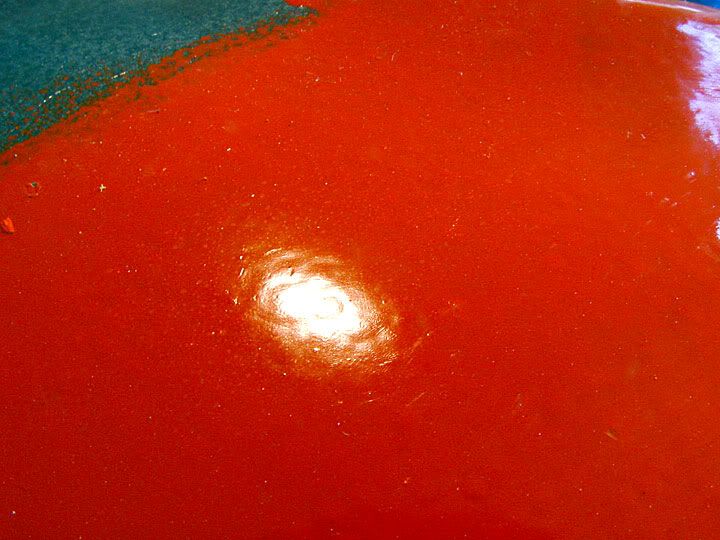

One thing that's tricky is the amount of pressure to use. Sometimes I don't even realize I'm using as much pressure as I am because this machine's so steady. You can gauge pressure with the PC by sound...(i.e. when it bogs down) , but you don't get the same audible cues with the RO. I'll figure it out , though.....eventually

Thanks for offering the help----I may take you up on it.

I have been keeping it in the same speed range as you mentioned to good effect. This machine's a good bit more powerful than the PC , and you're right , it takes a bit of patience and re-learning with combos.

One thing that's tricky is the amount of pressure to use. Sometimes I don't even realize I'm using as much pressure as I am because this machine's so steady. You can gauge pressure with the PC by sound...(i.e. when it bogs down) , but you don't get the same audible cues with the RO. I'll figure it out , though.....eventually

Thanks for offering the help----I may take you up on it.