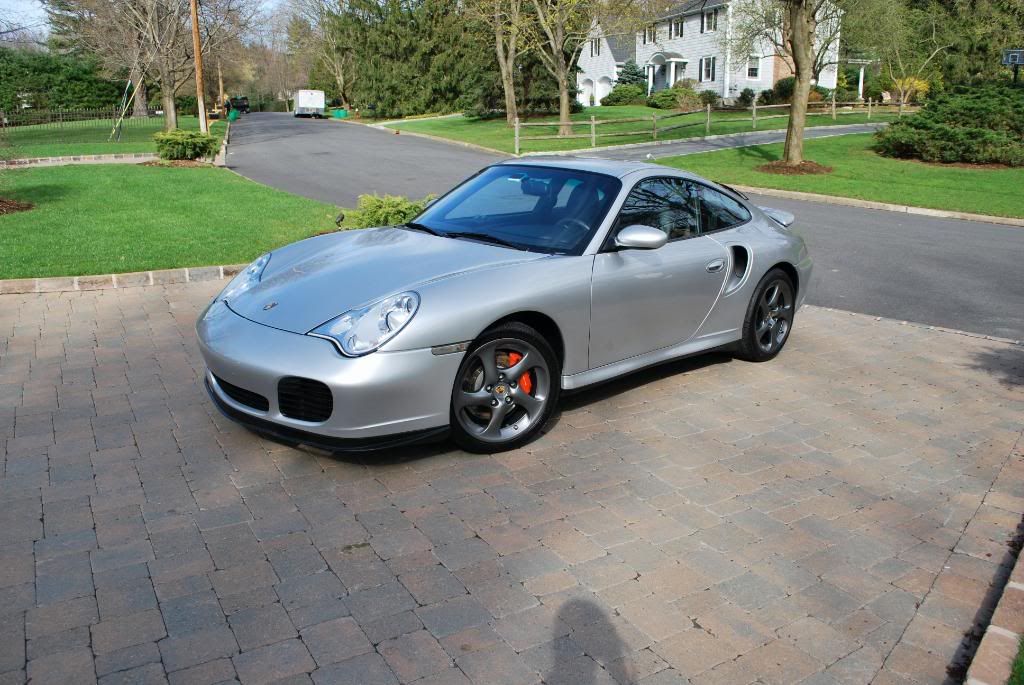

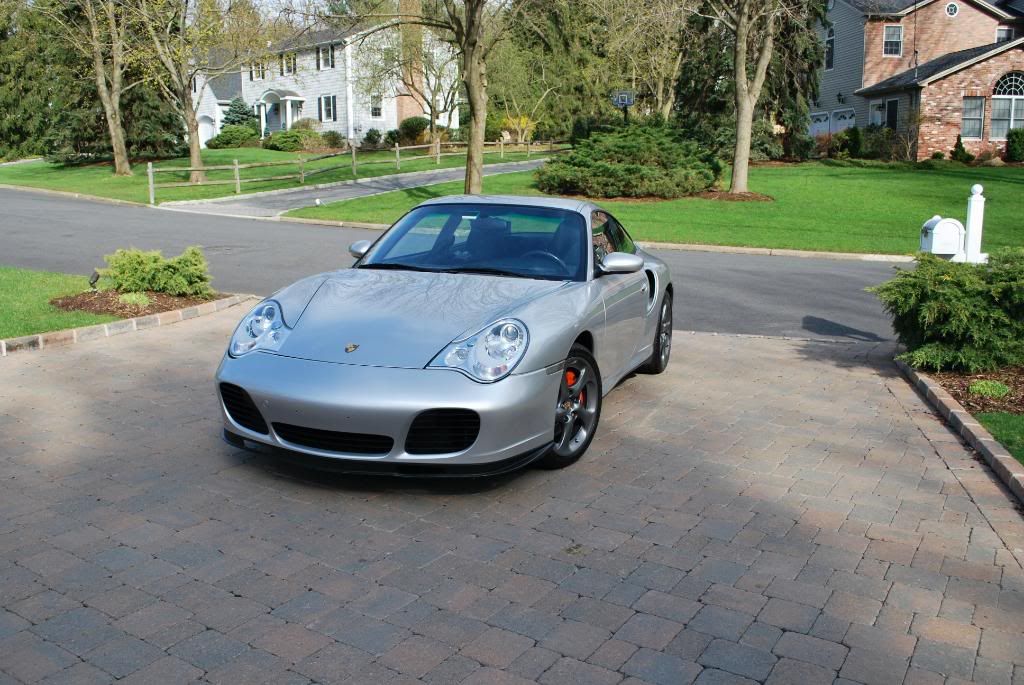

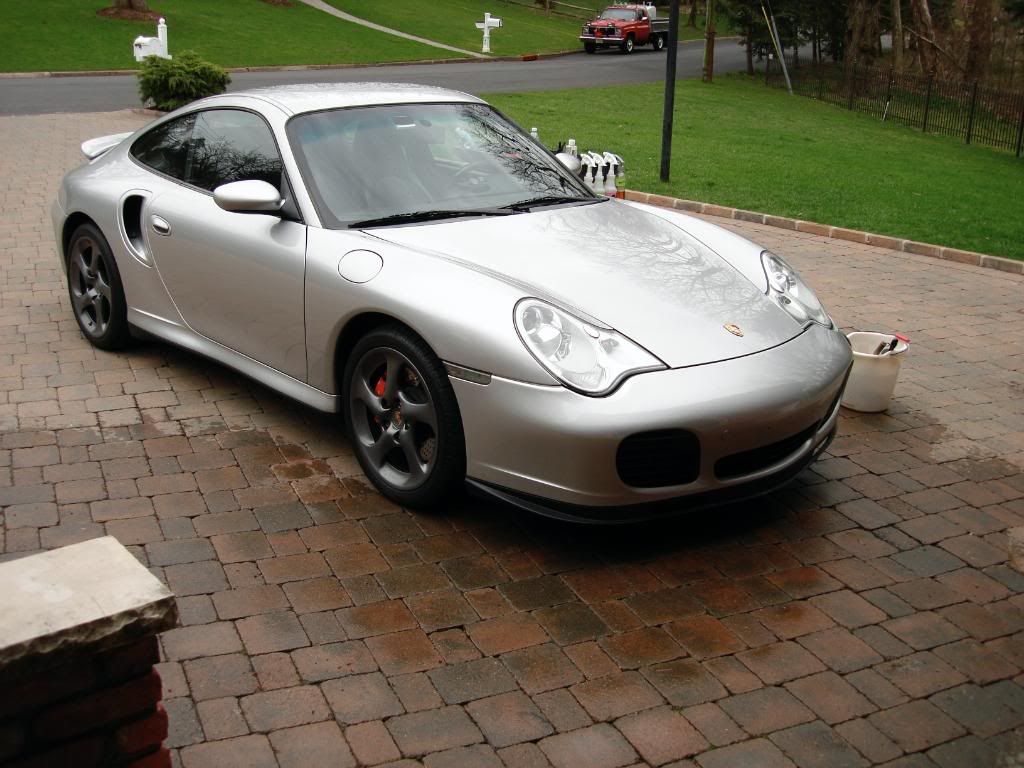

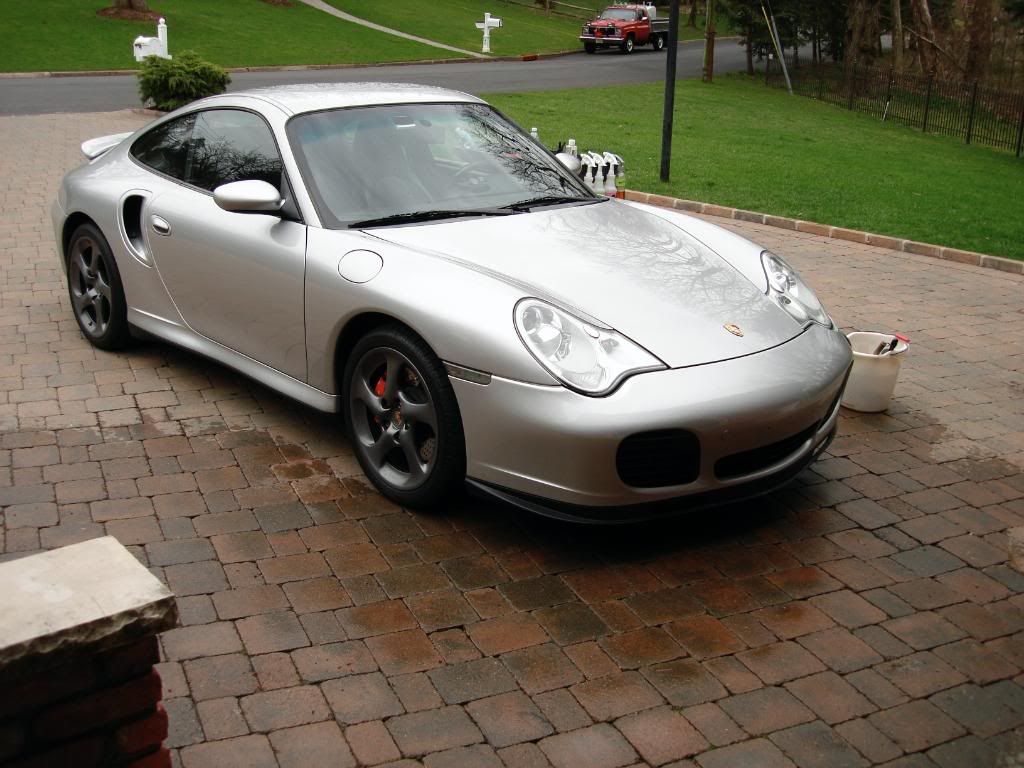

2003 996 turbo booked for a 2 day extensive detail

Upon arrival: no wash process pics sorry

Maxi suds foam

CWC 2BM

Gloss-It green mild clay

Gloss-It wheel gel 1:1

Megs APC 3:1

Stoners Tarminator (tires)

Autosmart Tardis

The owner wanted everything perfect and I was happy to go all out on a silver car for a change and not do the usual "1 step"

Starting with the headlights and Gloss It one step machine gloss w/ a compounding pad and followed up once more with a finishing pad

Drivers side before

After

Passenger side headlight under the LED

Even with 3 or 4 different light sources it was pretty difficult to pick up the defects on camera, the car had a lot of wash induced stuff and some deeper RIDS (the hood needed some wetsand attention)

Door under the LED... light being refracted in a million directions

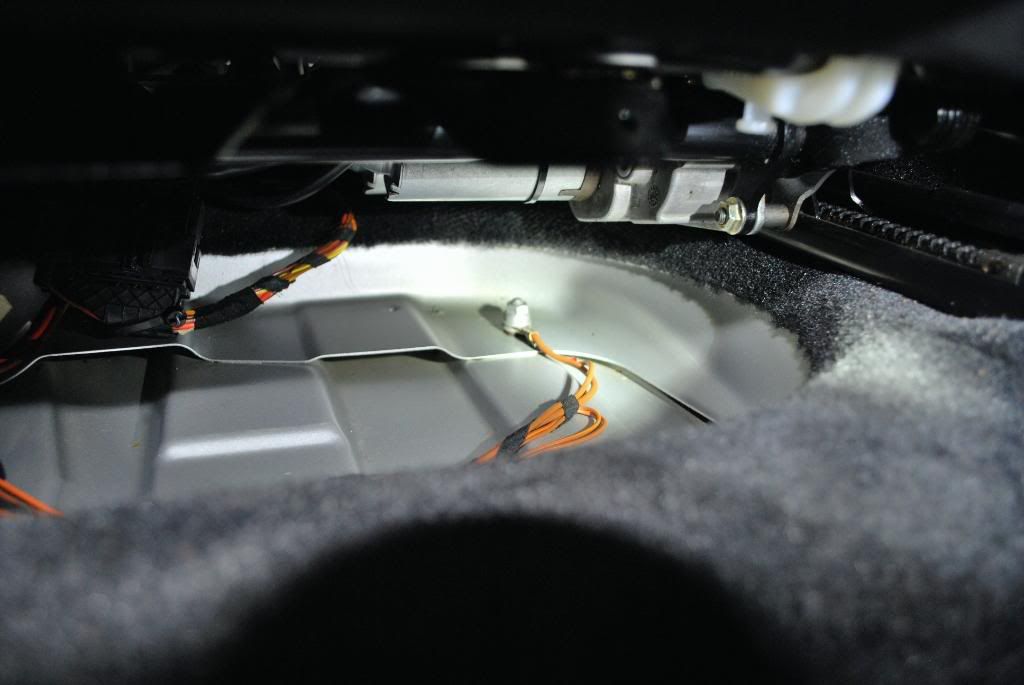

A cluster of scratches by the drivers side windshield had to be wetsanded, as usual I picked one scratch to test

Before 2000grit

After

2000grit compounded out with Gloss It extreme cut worked well on the test scracth so I proceeded to take care of the rest of the cluster with 5 or 6 more

After spot compunding the sanded areas the rest of the car recieved a 2 step process. The paint was a little stickier than expected so I broke out the Flex DA for the first time in 6months and I wondered why I left it collecting dust for so long:shead:

Gloss-It Evolution cut w. GI green/yellow polishing pad Flex 3401

Gloss-it Evolution polish w. GI blue finishing pad Flex 3403

Gloss-it EVP pad primer

Even though the flex random did an excellent job on the first part of correction I still broke out the rotary for jeweling as I find I can refine the finish a bit more working slow passes at low RPM. The GI polishes are a no brainer for sticky paints btw!

I rarely get the chance to go for 100% correction on silver or white cars but this car is very special to the owner as he wanted everything to restored to as close to new condition as possible.

Working evolution cut (some areas needed the little flex rotary as the flex random was too big)

jeweling

The taillights were a bit faded w/ some moderate swriling as well so the saem 2 step process as before was carried out

After

The "mystery" exhaust system on the turbo took about 40minutes of hand cleaning and polishing to get back to a presentable state

Noxon metal polish

#00 steel wool (inside the tailpipes only)

#0000 steel wool (outside tailpipes)

re-polished w/ Noxon using a finger pad

Before

After

The trim was well dried out, first I did a thorough cleaning with IPA and then applied Gloss It TRV dressing using a foam stick (pictured later and works great for applying any exterior dressing)

Before

I find the foam tipped stick is much more accurate for applying dressing in small areas (especially those areas next to paint)

Lower rocker panels finished

Before

After

Upon arrival: no wash process pics sorry

Maxi suds foam

CWC 2BM

Gloss-It green mild clay

Gloss-It wheel gel 1:1

Megs APC 3:1

Stoners Tarminator (tires)

Autosmart Tardis

The owner wanted everything perfect and I was happy to go all out on a silver car for a change and not do the usual "1 step"

Starting with the headlights and Gloss It one step machine gloss w/ a compounding pad and followed up once more with a finishing pad

Drivers side before

After

Passenger side headlight under the LED

Even with 3 or 4 different light sources it was pretty difficult to pick up the defects on camera, the car had a lot of wash induced stuff and some deeper RIDS (the hood needed some wetsand attention)

Door under the LED... light being refracted in a million directions

A cluster of scratches by the drivers side windshield had to be wetsanded, as usual I picked one scratch to test

Before 2000grit

After

2000grit compounded out with Gloss It extreme cut worked well on the test scracth so I proceeded to take care of the rest of the cluster with 5 or 6 more

After spot compunding the sanded areas the rest of the car recieved a 2 step process. The paint was a little stickier than expected so I broke out the Flex DA for the first time in 6months and I wondered why I left it collecting dust for so long:shead:

Gloss-It Evolution cut w. GI green/yellow polishing pad Flex 3401

Gloss-it Evolution polish w. GI blue finishing pad Flex 3403

Gloss-it EVP pad primer

Even though the flex random did an excellent job on the first part of correction I still broke out the rotary for jeweling as I find I can refine the finish a bit more working slow passes at low RPM. The GI polishes are a no brainer for sticky paints btw!

I rarely get the chance to go for 100% correction on silver or white cars but this car is very special to the owner as he wanted everything to restored to as close to new condition as possible.

Working evolution cut (some areas needed the little flex rotary as the flex random was too big)

jeweling

The taillights were a bit faded w/ some moderate swriling as well so the saem 2 step process as before was carried out

After

The "mystery" exhaust system on the turbo took about 40minutes of hand cleaning and polishing to get back to a presentable state

Noxon metal polish

#00 steel wool (inside the tailpipes only)

#0000 steel wool (outside tailpipes)

re-polished w/ Noxon using a finger pad

Before

After

The trim was well dried out, first I did a thorough cleaning with IPA and then applied Gloss It TRV dressing using a foam stick (pictured later and works great for applying any exterior dressing)

Before

I find the foam tipped stick is much more accurate for applying dressing in small areas (especially those areas next to paint)

Lower rocker panels finished

Before

After