Todd@RUPES

Just a regular guy

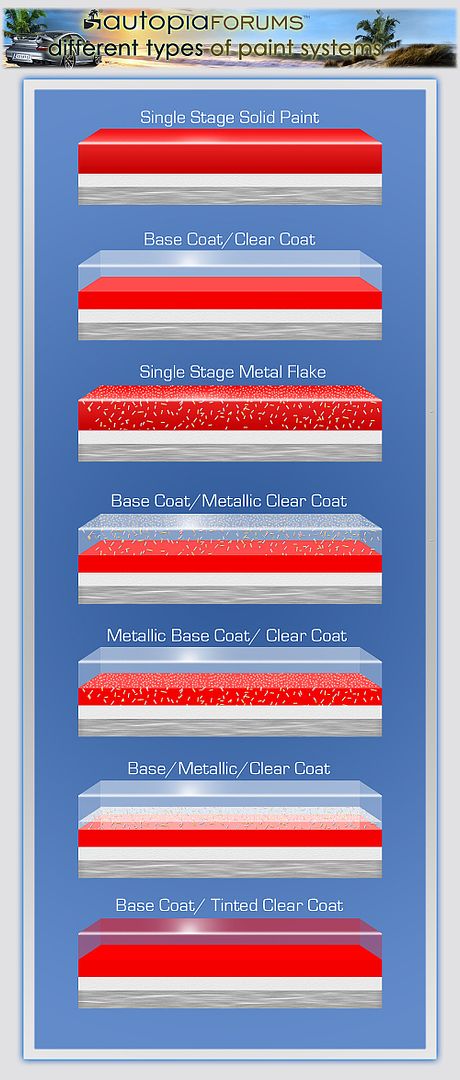

The different type of paint systems used today at the OEM (factory) and aftermarket level varies wildly. Below is a chart that shows the cross section of different types of single stage and base coat/clear coat paint systems, as well as some of the different ways metal flake may be incorperated into the paint.

Single Stage paints are rarely used at the OEM level. In a single stage paint the color coat (base coat) is exposed. When you polish single stage paint you will get get color transfer from the paint to your polishing pad.

Base Coat/Clear Coat paints are commonly used at the factory level and extremely common in most aftermarket paints. The color is contained in the base coat, which is usually dull or semi-reflective. Several coats of clear paint are applied over the base coat to provide UV protection and shine.

With special effect colors such as a candy coats, pearls, and metallic flake, the effects may be in the color coat, clear coat, or most commonly in thin layers sandwiched between the the various layers. With base/coat clear coats it is uncommon to find flake mixed into the clear coat, although it still happens. When polishing a paint system with flake mixed into the clear your polishing pad will turn black (like you are polishing metal).

Clear coats are not always clear, at the OEM level some manufactures add a small amount of pigment to the clear for a desired effect. This is known as a tinted clear coat. Victory Red Metallic, found on Corvettes (and a similar hue on Cadillacs), has a tinted clear. You will notice some color transfer when polishing these paints, although nothing as dramatic as with a single stage paint.

When dealing with high end specialty and custom paint jobs, all bets are off. Painters will add different levels of effects and mix and match effects in order to give a desired effect. This is done at the OEM level as well (to a lesser degree) such as Lamborghini's tri-coat pearl orange paint which features a base coat of orange base, a flake, a pearl-flake, and finally clear coat (for four layers despite the name).

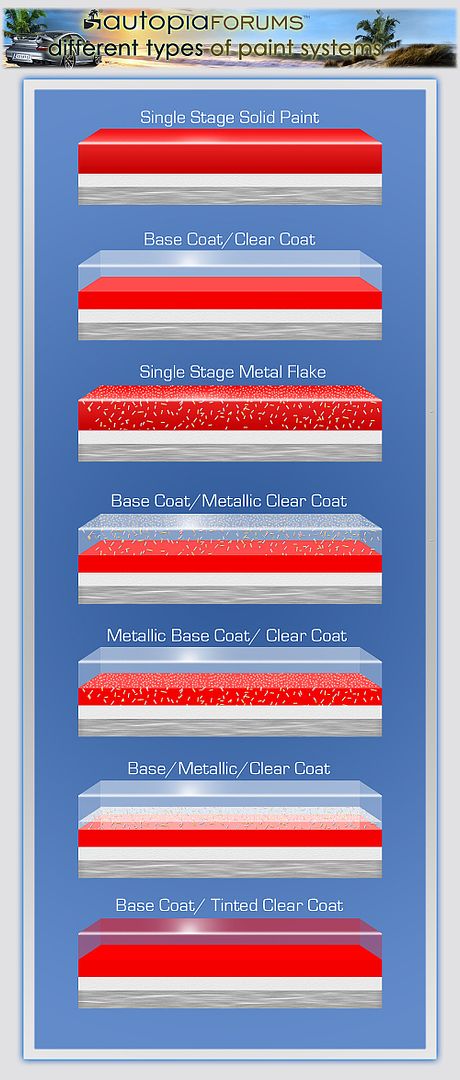

Single Stage paints are rarely used at the OEM level. In a single stage paint the color coat (base coat) is exposed. When you polish single stage paint you will get get color transfer from the paint to your polishing pad.

Base Coat/Clear Coat paints are commonly used at the factory level and extremely common in most aftermarket paints. The color is contained in the base coat, which is usually dull or semi-reflective. Several coats of clear paint are applied over the base coat to provide UV protection and shine.

With special effect colors such as a candy coats, pearls, and metallic flake, the effects may be in the color coat, clear coat, or most commonly in thin layers sandwiched between the the various layers. With base/coat clear coats it is uncommon to find flake mixed into the clear coat, although it still happens. When polishing a paint system with flake mixed into the clear your polishing pad will turn black (like you are polishing metal).

Clear coats are not always clear, at the OEM level some manufactures add a small amount of pigment to the clear for a desired effect. This is known as a tinted clear coat. Victory Red Metallic, found on Corvettes (and a similar hue on Cadillacs), has a tinted clear. You will notice some color transfer when polishing these paints, although nothing as dramatic as with a single stage paint.

When dealing with high end specialty and custom paint jobs, all bets are off. Painters will add different levels of effects and mix and match effects in order to give a desired effect. This is done at the OEM level as well (to a lesser degree) such as Lamborghini's tri-coat pearl orange paint which features a base coat of orange base, a flake, a pearl-flake, and finally clear coat (for four layers despite the name).