orion613719

New member

This is a black Honda Civic Hood. Can you finish this panel in 4 passes?

A few days ago, while being really frustrated with the holograms on a black Camry,

I discovered something I will refer to as “Orion Chang Method ”

Kevin Brown Method(KBM) has been around pretty much all the detailing forums.

From my understanding it uses the DA to its full potential with just 1 polish and 1 pad.

KBM seems to be able to cut hard, yet finish down nearly perfect. It takes a bit of patience,

and takes a toll on the pad.

My method focuses on the rotary. Starting with #2000 sanding marks,

it’s able to reach perfect finish in 4 passes.

Tools needed:

I’ve done a lot of tests, LC red and Menzerna 83Q works best in this case.

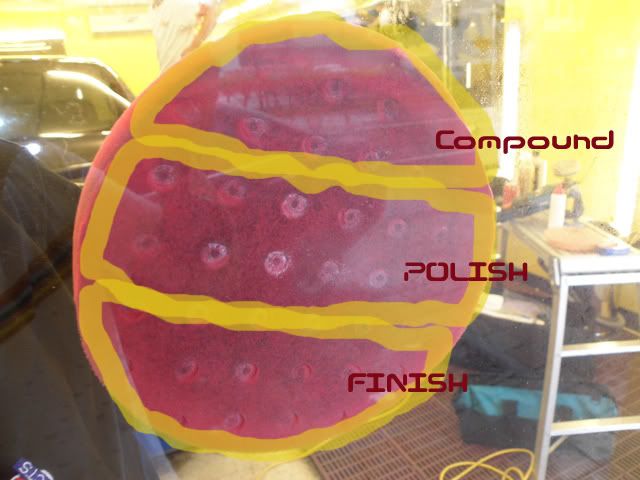

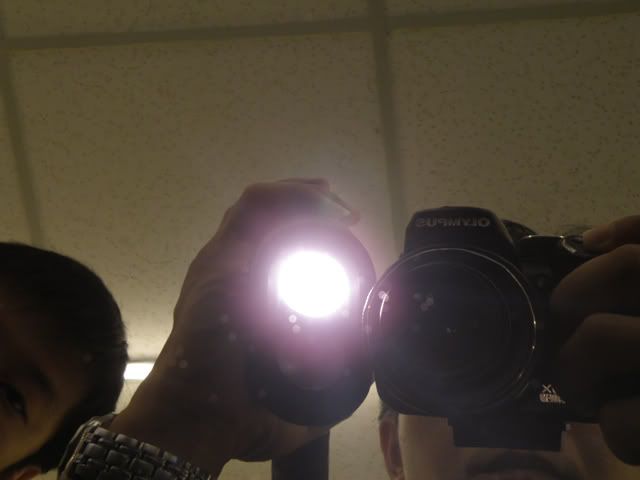

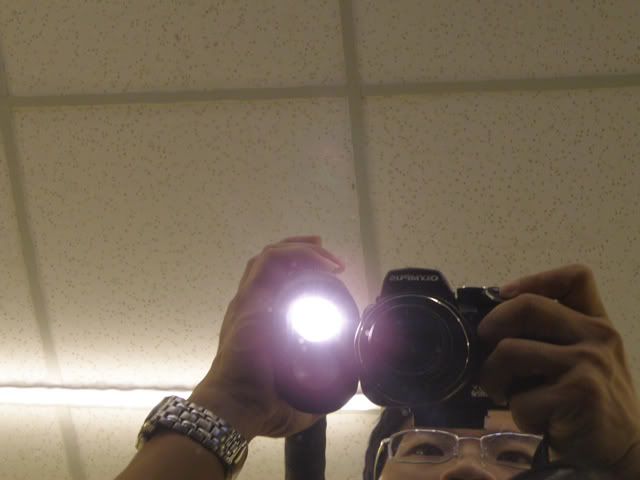

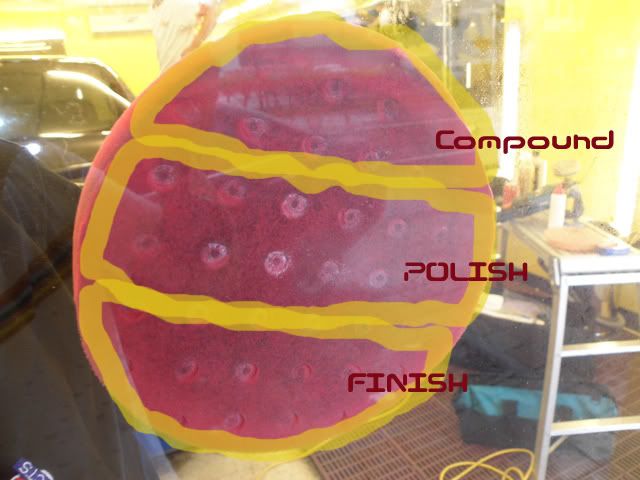

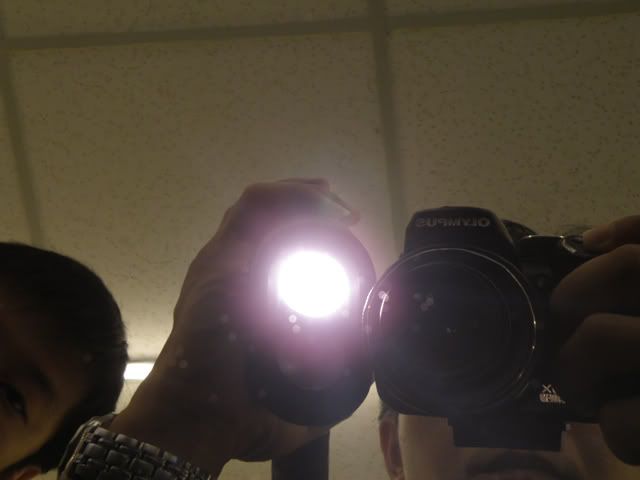

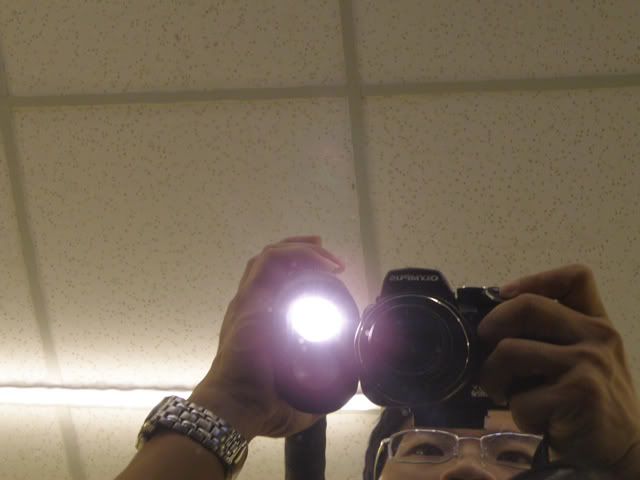

The following 2 pictures show the mechanics of the method.

The pressure is focused only on the left side, while lifting the right side enough for

the pad to be barely gliding on the paint. You would always move towards the pressure side,

so the lifted side will finish down smoother. With any luck, compounding, polishing, finishing

will be done with the same pad and polish.

Like in a CNC machining environment, you don’t cut back and forth. If you do cut back and forth,

finish would become very rough. So we imitate the same process with our polisher.

The traditional method puts the pad flat on the surface, despite the possible curves on the panels.

This usually makes us put slightly more weight on the side we’re moving away from so we can handle

the machine movement better. This has a higher tendency of leaving swirls/holograms that is equal

or deeper than the polish/pad combination.

What I’m doing is reversing the mechanics - Having more pressure on the initial cut, and finishing

down as you’re moving away.

Some pictorials:

You only need a about 4 drops of 83Q evenly spread throughout the radius of the pad, any more it splatters.

Speed 1 to spread the polish.

Polish at 800rpm.

Short video clip of the method

YouTube - OCM

This picture shows the difference in the density of the contact – strong on one side, weak on the other. This shows the difference in the cutting strength.

This is the result

Do note that the surface temperature rises VERY quickly.

Working OCM on actual car

The finish looks awesome!

After doing 2/3 of the car, the pad is unharmed.

A few days ago, while being really frustrated with the holograms on a black Camry,

I discovered something I will refer to as “Orion Chang Method ”

Kevin Brown Method(KBM) has been around pretty much all the detailing forums.

From my understanding it uses the DA to its full potential with just 1 polish and 1 pad.

KBM seems to be able to cut hard, yet finish down nearly perfect. It takes a bit of patience,

and takes a toll on the pad.

My method focuses on the rotary. Starting with #2000 sanding marks,

it’s able to reach perfect finish in 4 passes.

Tools needed:

I’ve done a lot of tests, LC red and Menzerna 83Q works best in this case.

The following 2 pictures show the mechanics of the method.

The pressure is focused only on the left side, while lifting the right side enough for

the pad to be barely gliding on the paint. You would always move towards the pressure side,

so the lifted side will finish down smoother. With any luck, compounding, polishing, finishing

will be done with the same pad and polish.

Like in a CNC machining environment, you don’t cut back and forth. If you do cut back and forth,

finish would become very rough. So we imitate the same process with our polisher.

The traditional method puts the pad flat on the surface, despite the possible curves on the panels.

This usually makes us put slightly more weight on the side we’re moving away from so we can handle

the machine movement better. This has a higher tendency of leaving swirls/holograms that is equal

or deeper than the polish/pad combination.

What I’m doing is reversing the mechanics - Having more pressure on the initial cut, and finishing

down as you’re moving away.

Some pictorials:

You only need a about 4 drops of 83Q evenly spread throughout the radius of the pad, any more it splatters.

Speed 1 to spread the polish.

Polish at 800rpm.

Short video clip of the method

YouTube - OCM

This picture shows the difference in the density of the contact – strong on one side, weak on the other. This shows the difference in the cutting strength.

This is the result

Do note that the surface temperature rises VERY quickly.

Working OCM on actual car

The finish looks awesome!

After doing 2/3 of the car, the pad is unharmed.