Todd@RUPES

Just a regular guy

Polishing paint involves using abrasive materials to create a controlled level of friction. This friction smooths away imperfections, and when done correctly, leaves the paint looking factory fresh, void of any gloss-hindering defects such as swirl marks and micro scratches.

A by product of friction is heat. This is easy to mimic. Press your palms together and rub vigorously, back-and-forth, until you feel your hands begin to warm. Rub harder and faster and it is possible to heat your hands to the point that they hurt.

While heating paint does offer some benefits very minor benefits, over all it is an unwanted by product which offers more drawbacks. When paint is overheated it can become permanently damaged.

What Advantages Does Heat Offer

The only advantage that heat offers, when considered for polishing, is it MAY soften the paint/clear coat slightly, resulting in a faster correction. That's it.

What Disadvantages Does Heat Create?

As mentioned above, heat will act to slightly soften the paint/clear coat. In extreme cases heat can cause the paint become unstable, leading to wrinkling, shrinking, texture changing, burning or many other permanent and unwanted effects. In addition, excessive heat is responsible for the following

How Hot Is Too Hot?

After consulting with several paint experts and chemists, as well as the car/paint care experts, the general consciousness is that temperatures above 180-200 degrees should be avoided. Temperatures above 230 degrees can, and likely will, lead to long-term damage. Sadly we have seen some detailers, even those who claim to be experts, brag about making paint smoke as they detail it. Since paint will smoke around 240 degrees, these "experts" have been bragging about damaging paint finishes.

Keep in mind that black or dark paint can reach as high as 180 degrees in the sun. However, they are not subjected to any friction or abrasive action when this hot, so they expand with the substrate and cool off with no problem.

So Let's Heat Some Paint!

One of the benefits of my job is I get to do cool things... seriously! I pulled a test paint panel into the garage, armed with some tools, to test the effect of purposely overheated paint.

In order to over heat the paint I grabbed the powerful direct-drive FLEX PE Rotary Polisher, a closed-cell foam cutting pad, and the abrasive Menzerna FG400 compound. This is an aggressive combination, that when used properly, will produce amazing results... However, my goal was to use these products incorrectly to overheat the paint.

I also grabbed the accurate Mircro-Tech Infrared Temp Gauge to measure heat.

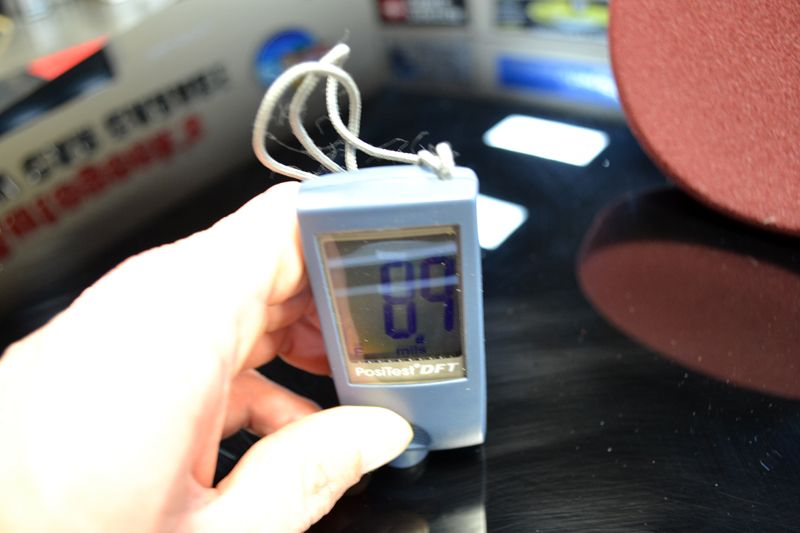

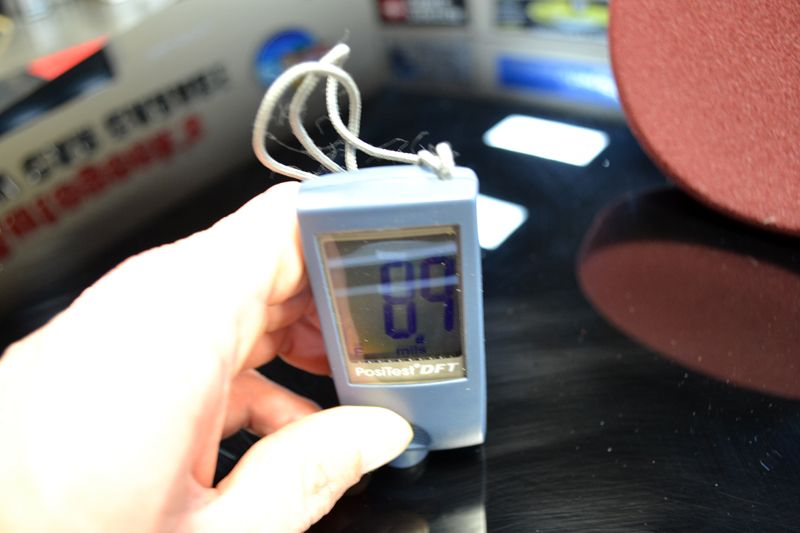

In order to measure the amount of paint removed during this process I used the trusty DeFlesko PosiTector to measure total thickness. It was 8.9 mils thick at the beginning.

Bad technique on purpose!!! I set the FLEX PE to maximum speed: 2100RPM. In addition I polished a very small section, barely wider than the diameter of the pad, and used enough pressure to audibly slow the powerful 800-watt motor. Combined with an aggressive closed-cell foam and polish, this could be considered the worst possible technique!

Let's get started!

[ame="http://www.youtube.com/watch?v=wEuz-ZbD7q4"]Burning Paint on Purpose[/ame]

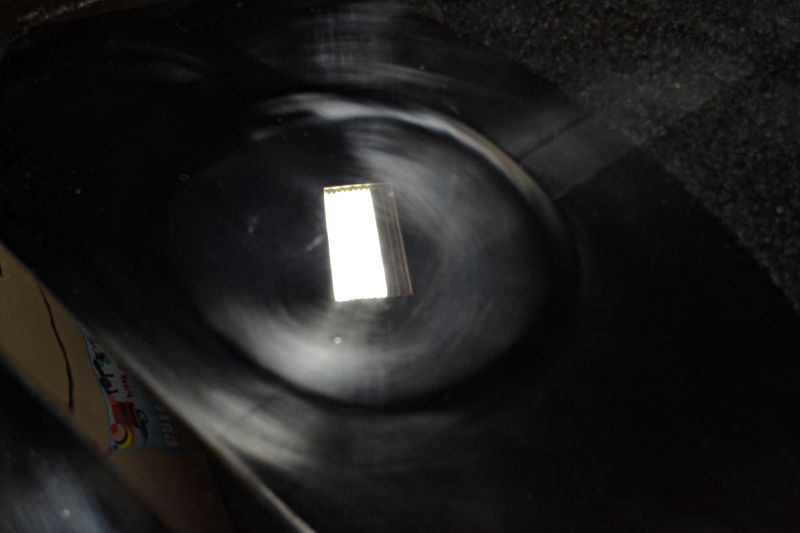

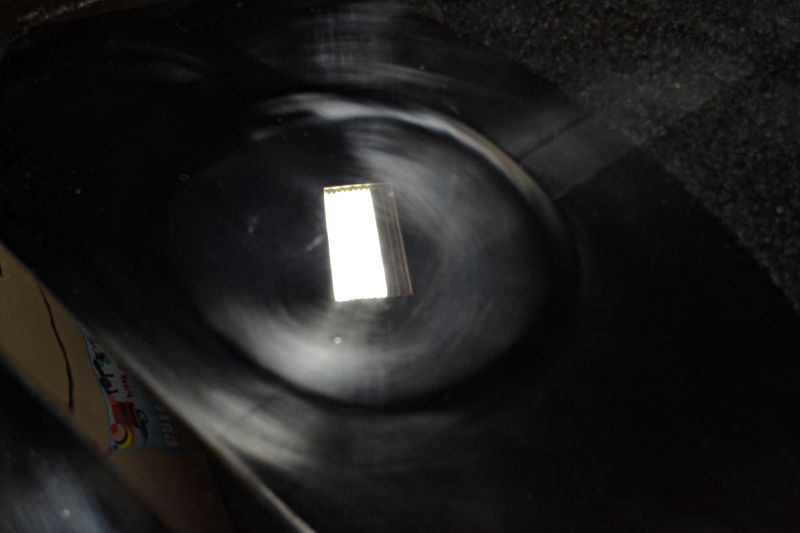

As you can see in the video, approximately 20 seconds after beginning to polish, the paint reached temperatures north of 240 degrees and started to smoke. It reached its maximum of 331 degrees just 10 seconds later, at which point is was heavily smoking. Below is some of the damage that has occurred.

What is important to remember that this type of damage is extreme and was created in a small amount of time. Remember, heating the paint above 200 degrees while polishing, for any length of time, is likely to cause long-term damage that may takes months or years to show.

Paint Swelling

One major drawback of overheating paint is paint swelling. Paint swelling has confused more than one detailer into thinking that paint can be "reflowed". Modern paint is cured chemically and can NEVER be reflowed. Much like plastic it can only be melted.

To illustrate the difference, remember that this paint originally measured 8.9 mils thick. Here is a thickness reading taken as the temperature cooled.

As you can see the paint, when heated measured 9.0 mils, showing a gain of 1/10th. However as the temp continued to drop, the thickness did as well. Soon the paint settled into a thickness of 8.7 mils, and when checked in the same exact spot 8 hours later: 8.6 mils.

Factors That Affect Temperature Change

It is import to remember that friction creates heat. Increasing cutting power will increase heat. However, there are factors that we can control that not only limit the amount of heat created, but more importantly, control how quickly that heat is dissipated.

A by product of friction is heat. This is easy to mimic. Press your palms together and rub vigorously, back-and-forth, until you feel your hands begin to warm. Rub harder and faster and it is possible to heat your hands to the point that they hurt.

While heating paint does offer some benefits very minor benefits, over all it is an unwanted by product which offers more drawbacks. When paint is overheated it can become permanently damaged.

What Advantages Does Heat Offer

The only advantage that heat offers, when considered for polishing, is it MAY soften the paint/clear coat slightly, resulting in a faster correction. That's it.

What Disadvantages Does Heat Create?

As mentioned above, heat will act to slightly soften the paint/clear coat. In extreme cases heat can cause the paint become unstable, leading to wrinkling, shrinking, texture changing, burning or many other permanent and unwanted effects. In addition, excessive heat is responsible for the following

- Paint Swelling - A condition in which heat and/or solvents cause the paint to swell, hiding imperfections and making it impossible to remove them.

- Paint Softening- On a cold day asphalt is as hard as a rock. On a hot day, black top can become so hot that your shoes leave imprints. The abrasives in a polish can leave imprints in hot paint, which become visible as the paint cures. This results in dye back - a condition in which hazing or holograms reappear hours or days after polishing.

- Poor Polish Performance- Polishes feature an oil or water-based lubricant which allows them to stay wet and remove paint defects without scouring the paint's finish. As the heat increase, the lubricants ability to protect the finish decreases leading to an increase in scouring. Too much heat will dry up the lubricants completely, resulting in even greater temperature spike.

- Decreased Pad Life- Excessive heat will greatly effect the stability of the foam and weaken the adhesive that holds the Velcro-like material to the pad.

How Hot Is Too Hot?

After consulting with several paint experts and chemists, as well as the car/paint care experts, the general consciousness is that temperatures above 180-200 degrees should be avoided. Temperatures above 230 degrees can, and likely will, lead to long-term damage. Sadly we have seen some detailers, even those who claim to be experts, brag about making paint smoke as they detail it. Since paint will smoke around 240 degrees, these "experts" have been bragging about damaging paint finishes.

Keep in mind that black or dark paint can reach as high as 180 degrees in the sun. However, they are not subjected to any friction or abrasive action when this hot, so they expand with the substrate and cool off with no problem.

So Let's Heat Some Paint!

One of the benefits of my job is I get to do cool things... seriously! I pulled a test paint panel into the garage, armed with some tools, to test the effect of purposely overheated paint.

In order to over heat the paint I grabbed the powerful direct-drive FLEX PE Rotary Polisher, a closed-cell foam cutting pad, and the abrasive Menzerna FG400 compound. This is an aggressive combination, that when used properly, will produce amazing results... However, my goal was to use these products incorrectly to overheat the paint.

I also grabbed the accurate Mircro-Tech Infrared Temp Gauge to measure heat.

In order to measure the amount of paint removed during this process I used the trusty DeFlesko PosiTector to measure total thickness. It was 8.9 mils thick at the beginning.

Bad technique on purpose!!! I set the FLEX PE to maximum speed: 2100RPM. In addition I polished a very small section, barely wider than the diameter of the pad, and used enough pressure to audibly slow the powerful 800-watt motor. Combined with an aggressive closed-cell foam and polish, this could be considered the worst possible technique!

Let's get started!

[ame="http://www.youtube.com/watch?v=wEuz-ZbD7q4"]Burning Paint on Purpose[/ame]

As you can see in the video, approximately 20 seconds after beginning to polish, the paint reached temperatures north of 240 degrees and started to smoke. It reached its maximum of 331 degrees just 10 seconds later, at which point is was heavily smoking. Below is some of the damage that has occurred.

What is important to remember that this type of damage is extreme and was created in a small amount of time. Remember, heating the paint above 200 degrees while polishing, for any length of time, is likely to cause long-term damage that may takes months or years to show.

Paint Swelling

One major drawback of overheating paint is paint swelling. Paint swelling has confused more than one detailer into thinking that paint can be "reflowed". Modern paint is cured chemically and can NEVER be reflowed. Much like plastic it can only be melted.

To illustrate the difference, remember that this paint originally measured 8.9 mils thick. Here is a thickness reading taken as the temperature cooled.

As you can see the paint, when heated measured 9.0 mils, showing a gain of 1/10th. However as the temp continued to drop, the thickness did as well. Soon the paint settled into a thickness of 8.7 mils, and when checked in the same exact spot 8 hours later: 8.6 mils.

Factors That Affect Temperature Change

It is import to remember that friction creates heat. Increasing cutting power will increase heat. However, there are factors that we can control that not only limit the amount of heat created, but more importantly, control how quickly that heat is dissipated.

- Paint Type - Different paints/clear coats, particularly those which are often described as "soft" can create a high temperature increase as they tend to grab at the pad more, increasing the friction.

- Machine Type- The type of machine used to polish will have a huge effect on the amount of temperature increase. Rotary tools, by their nature, while increase the temperature the most. Dual-action polishers, because of the flexing and twisting of the pad, will tend to dissipate heat through the pad much faster.

- Pad Type- Closed-cell foam pads will retain heat the most. Open-celled foam pads and wool pads tend to dissipate much more quickly because they allow the heat to flow out of the pad.

- Technique- Using too much pressure, tilting the pad or moving the machine too slowly can increase the amount of heat created in an isolated area. All three of these were done to create the video above.

- Substrate- The material under the paint can have a huge effect on how heat is dissipated across the surface. Metal body panels tend to radiate heat quickly, carrying heat away from the surface being polished. Composite materials such as rubber, plastic, fiberglass and carbon fiber tend to retain heat much longer, increasing the risk of overheating.