Todd@RUPES

Just a regular guy

Surbuf R Series Mico Finger Pads offer serious correction ability to DA users. These pads, because of the increased surface area they have, are capable of an immense amount of polishing action. They are different in use then a typical foam pad. This article will hopefully point on the differences and help you achieve maximum correction abillity from these unique pads.

Technical Stuff:

When you first look at a Surbuf R Series Pad the first thing you will likely notice is that the polishing face of the pad is covered with tiny hair-like material, like a buzz cut. These are called MicroFingers. These MicroFingers are densly packed and short. When polish is applied to the pad it coats to all 360 sixty degrees of the MicroFinger, which gives the Surbuf pad the ability to hold a lot more polish (and use more polish) then the flat face of a foam pad.

The tiny orbital movement of a Dual-Action polisher constantly exposes all of the 'sides (360 degrees)' of the MicroFinger so the amount of polishing actually working against the paint is far greater then the amount of polish a foam pad can engage. Much like the surface area of a full head of hair vs. a shaved or bald head.

Behind the MicroFinger face is a layer of open-celled foam that allows the MicroFingers to follow the curved surfaces. Behind the open-celled foam is a hook and loop attachment that allows SurBuf pads to be mounted on any traditional backing plate.

These pads are designed to be used with and perform best when used with a Dual-Action (Orbital) polisher.

Tips to getting the best performance.

Use the largest backing plate you can safely fit.

Surbuf pads are senstive to using the appropriate sized backing plate. The backing plate is responsible for transfering the motion of the machine to the motion of the pad directly. If you use a backing plate that is too small you will loose much of this motion, which greatly reduces the surface area of abrasives (from the polish) that work against the paint.

The picture below shows a 5 inch backing plate mounted on a 6.5 inch Surbuf R Series pad compared to a 6 inch backing plate mounted on a 6.5 inch Surbuf R Series pad. By using the smaller backing plate, you are effectively reducing the polishing action of the pad by a considerable amount. The 5 inch backing plate gives you an effective polishing area of approximately 19.63 inches squared, the 6 inch backing plate gives you an effective polishing area of approximately 28.26 inches squared. The larger backing plate engages the MicroFingers that would be traveling at the highest rate of speed so it is possible loose as much as 50% or more of your cutting action (polishing power) by using too small of a polishing pad.

Use a larger size and less pressure for more cut!

The Surbuf pads go against conventianal wisdom when it comes to achieving maximum polishing power. With most pads you want to increase pressure and use a smaller sized pad with a DA polisher.

The MicroFingers are most effective when they are standing up and down or slightly folded to the side, were the tiny orbital motion of the polisher will expose their entire surface. This allows the MicroFingers, each with abrasives attached to them, to whisk across the paint.

If the MicroFingers are compressed too much then the active surface area of the pad decreases to that of a flat pad and the advantages of the Surbuf pads are reduced signifcantly.

It is for the same reason that a larger pad can be more effective with the Surbuf pads. Even when you don't add pressure to the pad the machine is adding its own pressure. With the smaller Surbuf pads even the weight of the machine can cause the fingers to collapse. This can be countered by lifting slightly on the machine as you polish. The 6.5 inch and 7 inch Surbuf R Series pads seem to hold the weight of a DA polisher much better allowing you to polish with just the weight of the machine.

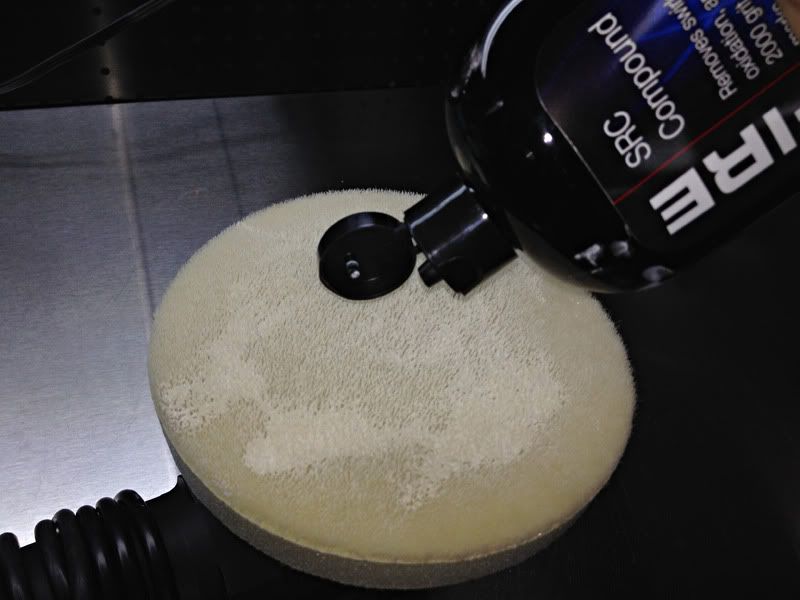

Prime the pad with the maximum amount of polish prior to first use.

Because the advantage of the Surbuf R Series pad is its abililty to expose a maximum amount of abrasives to paint at a give time, it only makes sense that we need to provide those abrasives to the paint. Priming the pad packs as much abrasives on the pad as possible. Once the pad is primed, use three small dots for additional sections and clean the pad by brushing or compressed air after each section.

Start priming by adding an ample amount of polish to the pad.

Work the polish into an even coat the completely covers the Surbuf pad.

Fill in any bare spots with additional polish and continue to work into the face of the pad until the entire surface is primed.

For additional sections only a small amount of additional polish is needed.

Surbuf Series R Pads are available at Autopia Car Care.com: Surbuf MicroFingers R Series Buffing Pads, surebuff, microfiber pads

Any questions or comments are welcome!