togwt

The Old Grey Whistle Test

Automotive paint

Paint surfaces are porous and can hold up to a pint of water after washing. They comprise contain microscopic peaks and valleys, much like the profile of a mountain range. These irregularities are known as capillary structures; there may be millions of these defects per square inch. Contaminants such as fine dirt, minerals, and pollutants are drawn into the voids where they are extremely hard to remove.

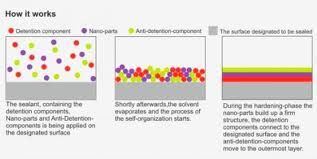

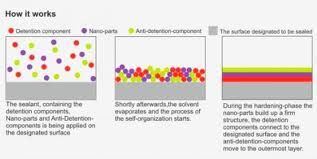

The filling of the capillary structures with nanoparticles produces a hydrophobic surface. (A hydrophobic surface is one that repels moisture.) In contrast, a hydrophilic surface is one that absorbs moisture. The potential of a surface to absorb or repel moisture is based on many factors, including: temperature, relative humidity, material homogeneity, and static electricity. Surface roughness is also a major factor; the rougher the surface, the higher the spreading rate or attraction for water. The smoother the surface, the more repellent it is to moisture.

The significance of a nano-coating is its small particle size that can form a very tight bond with the surface of most materials; including glass, paint, plastic, rubber, aluminium, chrome, stainless steel and fabrics, will have surface imperfections i.e. micro-fissures when viewed under high magnification. These undulations allow a nano-coating polymer to form a tight molecular bond (much like a printers ink when poured over paper that has writing indentations on it) with the surface it’s applied to. This level surface also improves paint surface clarity and reduce light scattering, providing improved light reflectance.

Paint sealants are synthetic products designed for long-term paint protection and easy application. They are composed mainly of amino functional polymers, which last longer than any natural wax and are highly resistant to the elements. Synthetic liquid waxes are another way of describing paint sealants. The main benefit of a paint sealant is their durability compared to a wax, polymer-based sealants will last anywhere from 3 to 6 months.

A coating is applied to a clean surface that surface takes on properties that are virtually identical to hardened glass. It is chemically inert and will not react with the base material. In other words, dirt will not bond to the treated surface, thereby reducing soiling and organic staining. Acid rain and other chemical compounds easily wash off, significantly reducing the hydroscopic nature of surfaces exposed to industrial or environmental pollution.

Nano Structure

Nanotechnology the science of nanotechnology; the creation, organization, or manipulation of materials, devices, or systems at the nanometre level

Nanotechnology, Nano particles or Nano structures, exactly what are they and how do they relate to detailing?

Most of these coatings are based around super siloxanes, and not true nanotube/tubule technology. This would cause a serious health concern for all of those - not to mention be ridiculously expensive. The context that “nano" (as related to detailing) is only as a relative size indicator merely to identify a siloxane/polymer.

They are sub micron particles that form a clear thin film of tightly packed nano particles forming an extension of the surface. The particles are up to a 1000 times denser which makes for an ultra durable hard wearing surface. Technically most detailing product particulates are not nano metre in size, although they are extremely small, as the term ‘nano’ adequately describes. Single-component coatings interlace on a molecular basis and form an extremely durable protective layer on the paint surface provided they are applied properly.They also improve paint surface clarity and reduce light scattering, providing improved light reflectance

Relevant Articles

1. “Nanotechnology coatings “- http://www.autopia.org/forum/autopia-detailing-wiki/136613-nanotechnology-coating-products.html

2. “Carnauba wax” - http://www.autopia.org/forum/autopia-detailing-wiki/138969-carnauba-wax-part-i.html#post1476919

3. Polymers Part I - http://www.autopia.org/forum/guide-detailing/138248-polymers-part-i.html#post1469073

Paint surfaces are porous and can hold up to a pint of water after washing. They comprise contain microscopic peaks and valleys, much like the profile of a mountain range. These irregularities are known as capillary structures; there may be millions of these defects per square inch. Contaminants such as fine dirt, minerals, and pollutants are drawn into the voids where they are extremely hard to remove.

The filling of the capillary structures with nanoparticles produces a hydrophobic surface. (A hydrophobic surface is one that repels moisture.) In contrast, a hydrophilic surface is one that absorbs moisture. The potential of a surface to absorb or repel moisture is based on many factors, including: temperature, relative humidity, material homogeneity, and static electricity. Surface roughness is also a major factor; the rougher the surface, the higher the spreading rate or attraction for water. The smoother the surface, the more repellent it is to moisture.

The significance of a nano-coating is its small particle size that can form a very tight bond with the surface of most materials; including glass, paint, plastic, rubber, aluminium, chrome, stainless steel and fabrics, will have surface imperfections i.e. micro-fissures when viewed under high magnification. These undulations allow a nano-coating polymer to form a tight molecular bond (much like a printers ink when poured over paper that has writing indentations on it) with the surface it’s applied to. This level surface also improves paint surface clarity and reduce light scattering, providing improved light reflectance.

Paint sealants are synthetic products designed for long-term paint protection and easy application. They are composed mainly of amino functional polymers, which last longer than any natural wax and are highly resistant to the elements. Synthetic liquid waxes are another way of describing paint sealants. The main benefit of a paint sealant is their durability compared to a wax, polymer-based sealants will last anywhere from 3 to 6 months.

A coating is applied to a clean surface that surface takes on properties that are virtually identical to hardened glass. It is chemically inert and will not react with the base material. In other words, dirt will not bond to the treated surface, thereby reducing soiling and organic staining. Acid rain and other chemical compounds easily wash off, significantly reducing the hydroscopic nature of surfaces exposed to industrial or environmental pollution.

Nano Structure

Nanotechnology the science of nanotechnology; the creation, organization, or manipulation of materials, devices, or systems at the nanometre level

Nanotechnology, Nano particles or Nano structures, exactly what are they and how do they relate to detailing?

Most of these coatings are based around super siloxanes, and not true nanotube/tubule technology. This would cause a serious health concern for all of those - not to mention be ridiculously expensive. The context that “nano" (as related to detailing) is only as a relative size indicator merely to identify a siloxane/polymer.

They are sub micron particles that form a clear thin film of tightly packed nano particles forming an extension of the surface. The particles are up to a 1000 times denser which makes for an ultra durable hard wearing surface. Technically most detailing product particulates are not nano metre in size, although they are extremely small, as the term ‘nano’ adequately describes. Single-component coatings interlace on a molecular basis and form an extremely durable protective layer on the paint surface provided they are applied properly.They also improve paint surface clarity and reduce light scattering, providing improved light reflectance

Relevant Articles

1. “Nanotechnology coatings “- http://www.autopia.org/forum/autopia-detailing-wiki/136613-nanotechnology-coating-products.html

2. “Carnauba wax” - http://www.autopia.org/forum/autopia-detailing-wiki/138969-carnauba-wax-part-i.html#post1476919

3. Polymers Part I - http://www.autopia.org/forum/guide-detailing/138248-polymers-part-i.html#post1469073