Todd@RUPES

Just a regular guy

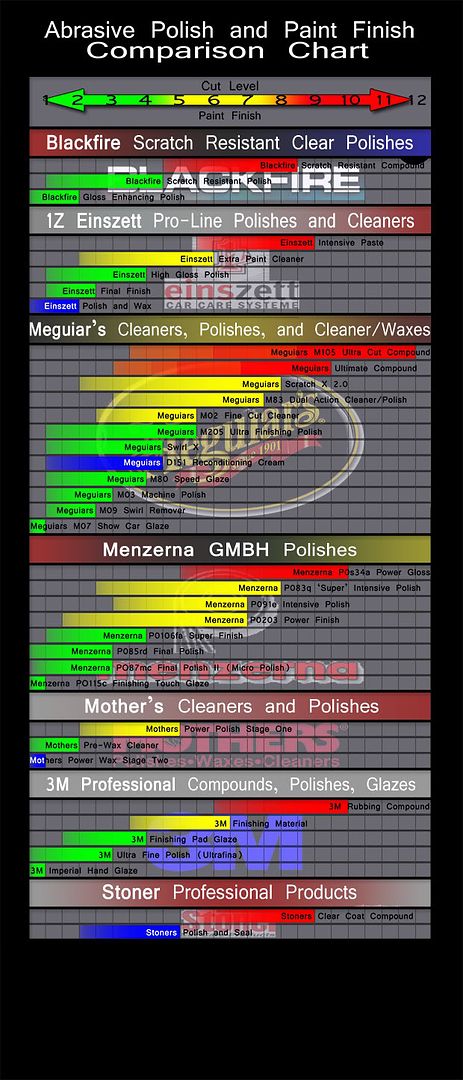

To my knowledge this is the first chart which offers a 'range' of working time which accounts for some of the variables associated with machine polishing.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Todd,

Nice chart very easy to read and understand. Perfect for amateurs like me.

Are these the results of your testing? I was under the impression that M205 had less cut than SwirlX. I'm going from the chart over at MOL.

I understand how the SMAT vs. DAT works (to a point) I am guessing that the cut number is controlled by the size of the abrasive in the SMAT technology.

Right now I use M205 and a Meg's 2.0 Black finishing pad on my black Camry every few months to remove light swirls and towel marks. I love the finish M205 leaves. However, If SwirlX does indeed have less cut, I can get the same results using it with a black pad. This can maybe save me some cc over the years to come

Thanks,

Mike

Here is my thought regarding your concern given that SMAT polishes are very dependent on work time for cut. The longer they are worked the more paint is removed. When we speak about cut regarding SMAT polishes we are really talking about the rate of paint removal vs. the amount of paint removal.

So M205 and SwirlX might have a different rate of removal, thus a different cut, but M205 is more likely to be applied via a professional machine with more aggressive techniques vs. SwirlX which would is more likely to be applied by hand. Thus when used in the most likely mannor, M205 should likely have a faster rate of defect removal. Does that make sense?

As far as what makes the polishes more abrasive, I am not privy to that information but I can say this. The abrasives in M105 are extremely fine, much finer then what you would have in most finishing polishes. I believe the cut (or rate of cut) is more affected by factors such as the lubricants used vs. different abrasives.

Thanks for chart:thumbup:. This is the kind of information that keeps me glued to TID. I would gladly purchase a laminated version, say, 11"(W) X 17"(H) but also realize that the manufacturer's may not approve...

Jack