Todd@RUPES

Just a regular guy

Chevy vs. Ford?

Ali vs. Frazier?

Pearl Jam vs. Nirvana?

Earnhardt vs. Gordon?

Senna vs. Schumacher?

Every generation and every genre has its rivalries. Perhaps you know some or all of the names above. When it comes to polishing paint, the debate on which will create a better finish, the rotary or random orbital polisher, rages on.

Rotary guys say that the rotary provides a better finish. Some of the reasons stated:

Random Orbital users contents that their dual-action polisher reigns supreme because:

So what's the truth? Which machine (rotary or random orbital) creates more gloss?

Smooth = Gloss

All things being equal, the paint with a smoother surface will reflect more light. This is true of any reflective surface. If we want to be completely accurate, the surface with a smoother finish will reflect the same amount of light, only it will do so more accurately, so that our eyes perceive more gloss.

So the real question is which polisher creates a smoother surface, the rotary or random orbital?

All Polishes Scratch

The second point to consider is that all abrasive machine polishes leave scratches in the paint. Polish grains (abrasives), in order to work, have to be harder than the paint's surface. As they tumble, rub or slide across the paint, they remove small impressions in the surface (usually 1/3 or less the size of the actual abrasive).

Building further on this, it is important to remember that modern abrasives are both designed to break apart and are extremely fine.

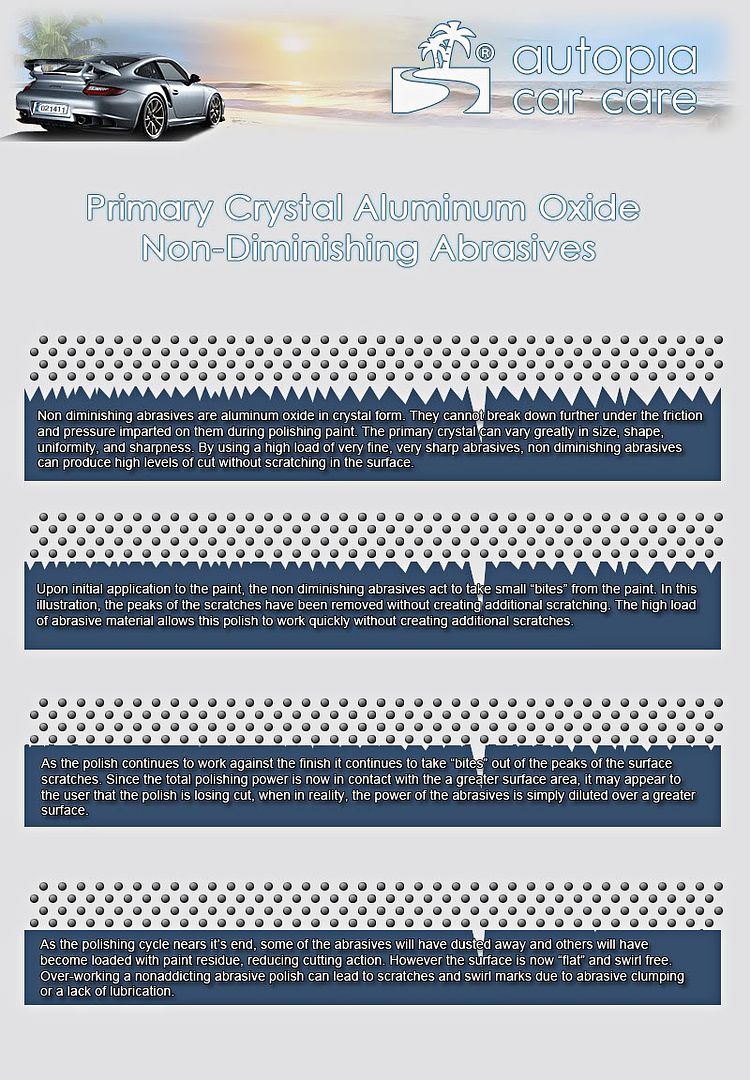

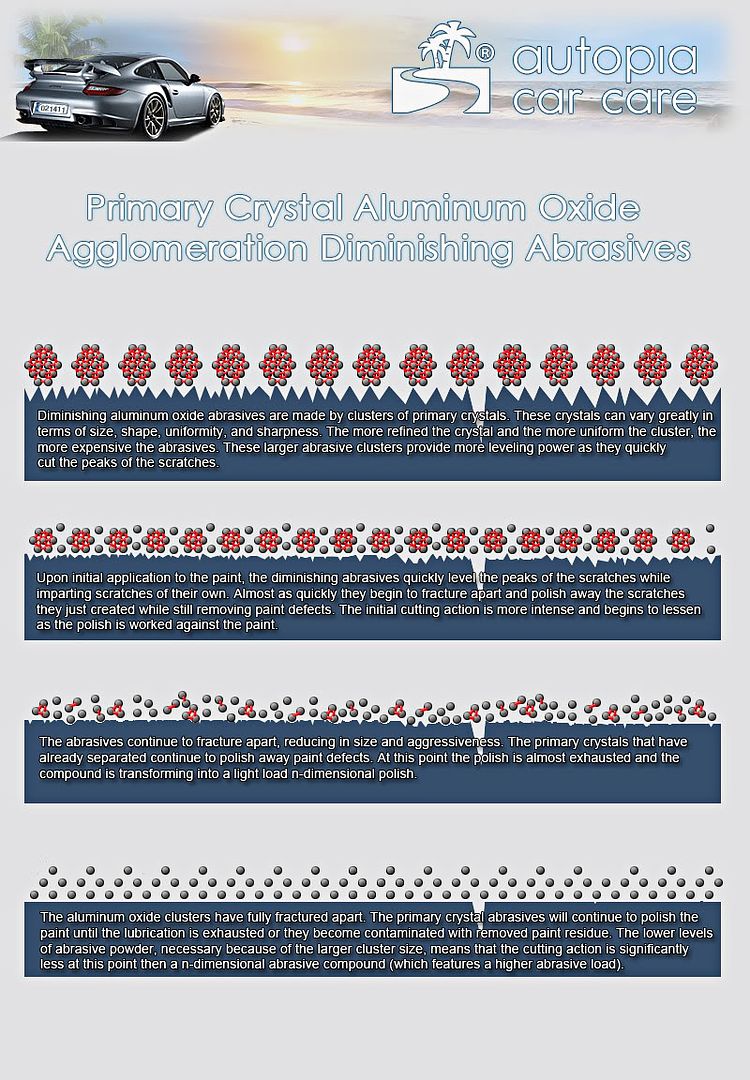

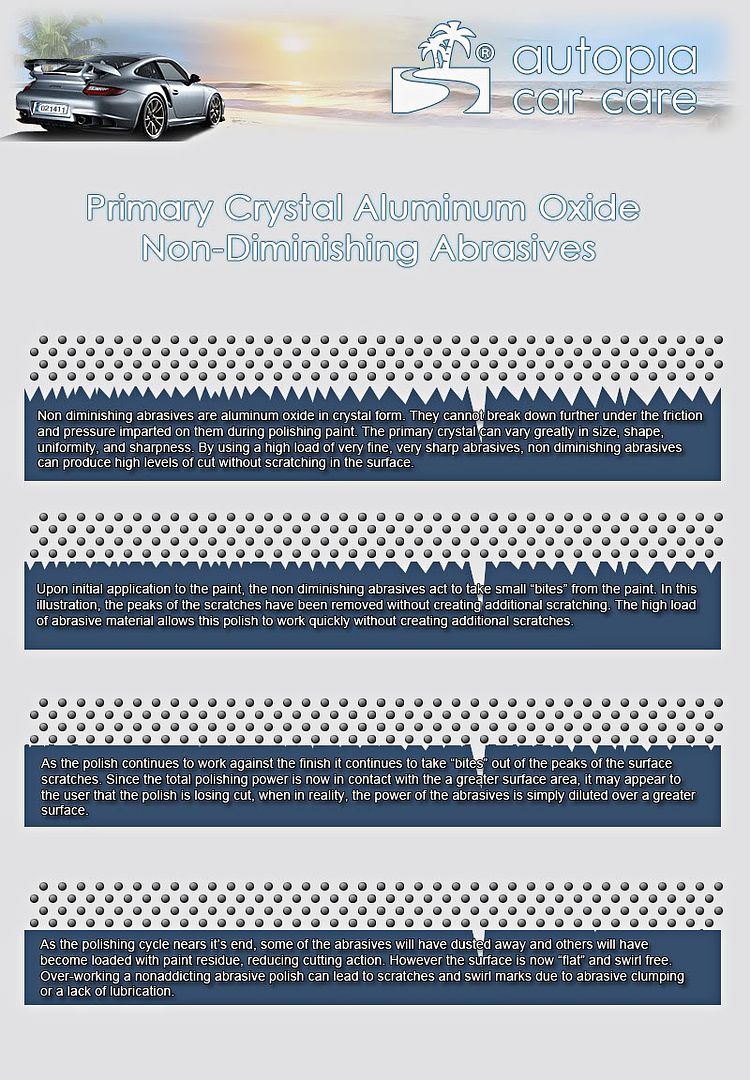

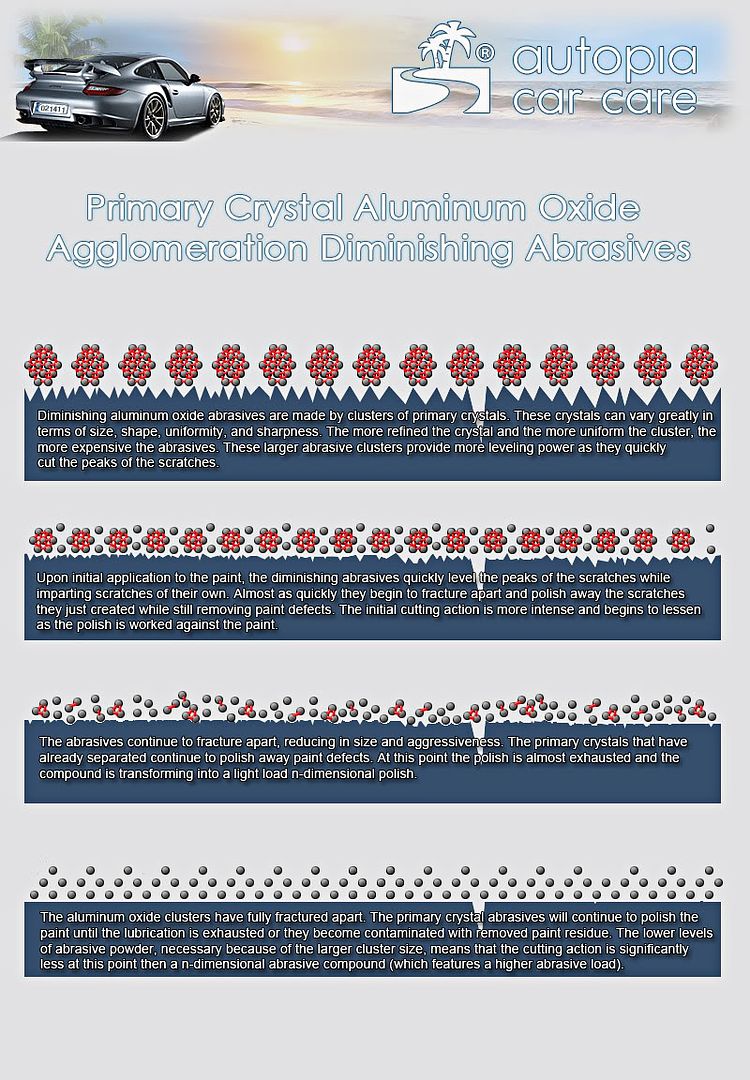

While these charts (below) were originally designed to display the difference between SMAT (super micro abrasive technology/non-diminishing abrasives) and DAT (diminishing abrasive technology) they hold some relevance for this post.

Regardless of the abrasive type used and the type of machine it is applied with, it is important to remember these facts:

Since the abrasives used in polishes have to be harder than paint to work, they have to be engineered to break apart or fracture, as the diminishing abrasive chart above demonstrates.

Non-diminishing abrasives are already "broken apart" and produce an extremely fine scratch pattern immediately.

Diminishing abrasives require some level of friction to fracture apart. However, rubbing a small amount of polish between your fingers will produce more than enough friction to quickly break modern diminishing abrasives apart.

While older, larger silica-based and diatomaceous earth abrasives could require a significant amount of friction to diminish, modern polishes simply do not. Regardless of the machine you use, modern abrasive technology will allow you to break down the abrasives fairly quickly.

Your Pad Plays A Role

Your polishing pad of choice plays a huge role in the finish quality you can achieve. The abrasive imprint left behind on the paint is partially controlled by how much the abrasive pushes into the pad as well as how well the pad's foam wall's squeegee the surface clean and entrap spent- abrasive material/paint residue.

Because an article, much longer than this, could be spent on how pad dynamics affect the polishing process, and the effect of different machines on pad dynamics, we will simply state that "all things being equal" applies to this article. This assumes, for this article, that the pad affects the abrasives identically (in terms of material capture and abrasive imprint).

Rotary vs. DA? What's The REAL Difference?

So far we have established the following:

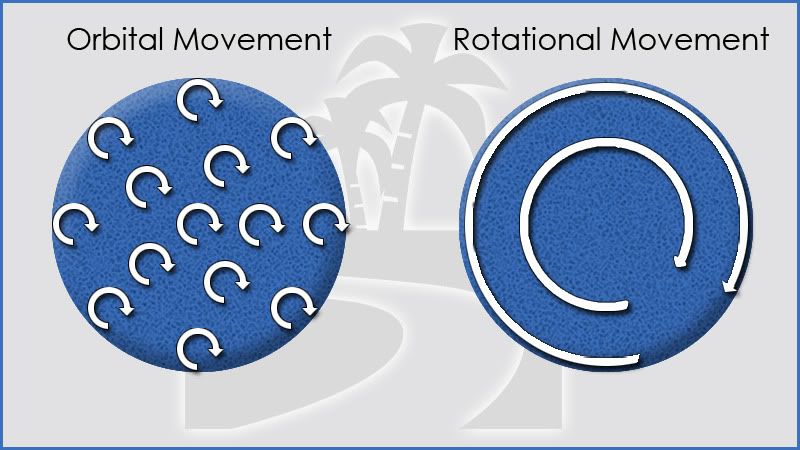

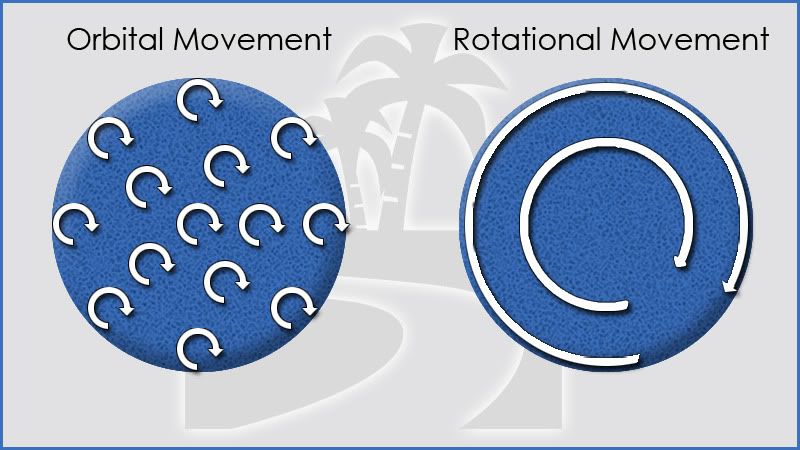

The main difference between a rotary and a random-orbital, dual-action polisher is the way they move the abrasives across the paint.

Rotary polishers are direct drive, and move the pad in a singular, planing motion across the paint.

Dual-Action Random Orbital polishers move the the pad in an orbital (tiny circles around a central point) motion as well as a spinning motion, creating a curly-q action.

The actions of each machine are illustrated in the diagram below:

Since the goal in creating a better finish boils down to leaving behind a smoother finish, which motion creates a better finish?

The simple answer is neither! All things being equal, both machines will leave similar-sized impressions in the paint, with the main difference being the scratch pattern left behind.

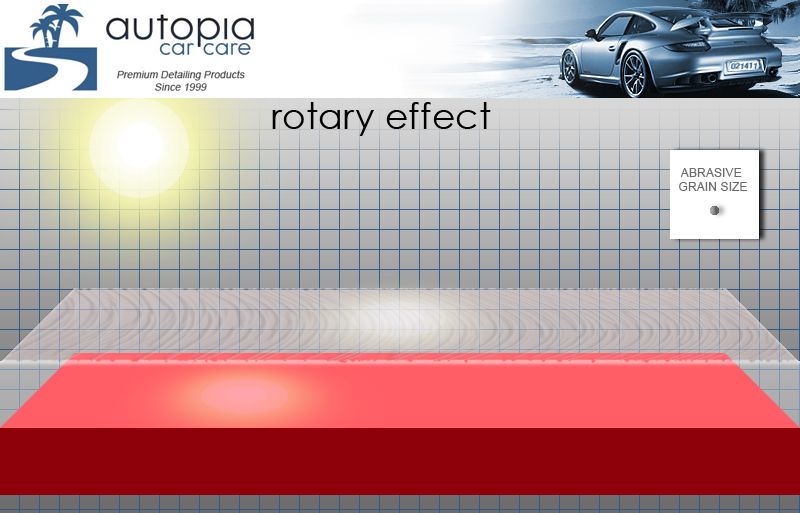

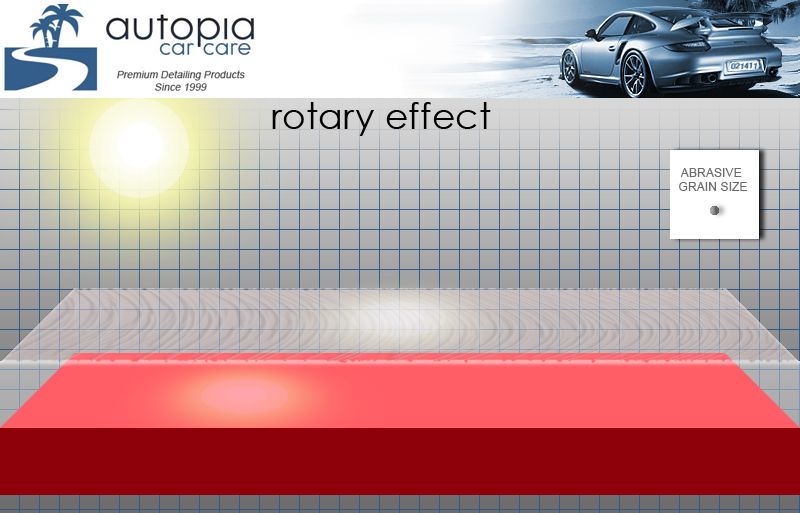

The diagram below shows the microscopic scratch pattern created by a rotary polisher:

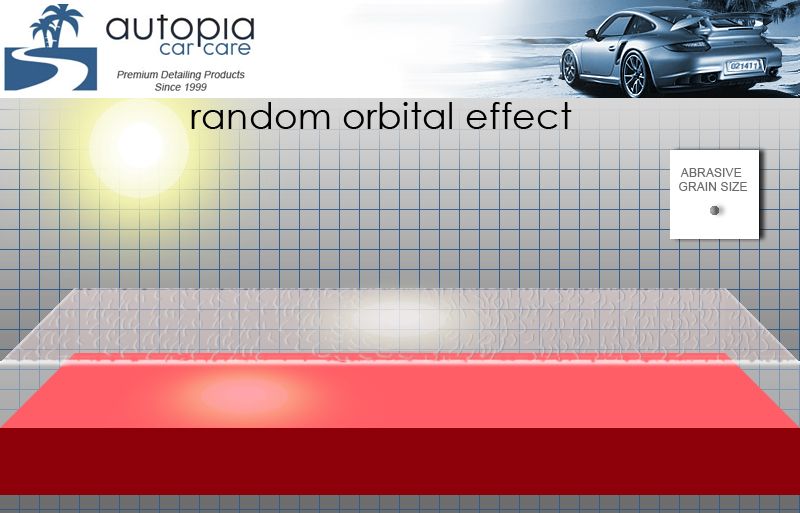

The diagram below shows the microscopic scratch pattern created by a dual-action random orbital polisher:

Because the scratch pattern of a dual-action random orbital polisher is dispersed across the paint in seemingly random pattern, it is LESS likely that you will see the scratch pattern.

IF you see a scratch pattern left behind by a rotary polisher, it will usually be in the form a hologram effect.

IF you see a scratch pattern left behind by a dual-action random orbital polisher, it will usually appear in the form of a light haze.

However, our eyes are far less likely to see a haze vs. a defined, uniformed hologram effect.

Which Machine Really Produces A Better Finish Depends On The User!

We have all seen the rotary user, with 20 years experience proudly proclaim that they can achieve a better finish with a rotary polisher.

By the same token, we have seen the guy who can create a perfect finish with a DA struggle with a rotary.

This is because changing the motion in which the machine drives the pad across the paint changes the entire dynamic of polish. Just because you have mastered one, or the other, does not mean you will automatically will be proficient with the other.

Because a dual-action random orbital polisher is less likely to create visible swirl marks and paint damage, it is often thought of as a simpler tool to master. In reality, there are far more dynamics involved with this style of polisher than a rotary, and thus it is more difficult to master.

At the end of the day, the tool you can achieve a better finish with will depend on your experience and comfort with that tool.

Ali vs. Frazier?

Pearl Jam vs. Nirvana?

Earnhardt vs. Gordon?

Senna vs. Schumacher?

Every generation and every genre has its rivalries. Perhaps you know some or all of the names above. When it comes to polishing paint, the debate on which will create a better finish, the rotary or random orbital polisher, rages on.

Rotary guys say that the rotary provides a better finish. Some of the reasons stated:

- It creates more heat

- It creates a more precise finish

- It breaks down the abrasives in a more even, more uniform manner

Random Orbital users contents that their dual-action polisher reigns supreme because:

- It creates less heat

- It creates less visible swirl marks

So what's the truth? Which machine (rotary or random orbital) creates more gloss?

Smooth = Gloss

All things being equal, the paint with a smoother surface will reflect more light. This is true of any reflective surface. If we want to be completely accurate, the surface with a smoother finish will reflect the same amount of light, only it will do so more accurately, so that our eyes perceive more gloss.

So the real question is which polisher creates a smoother surface, the rotary or random orbital?

All Polishes Scratch

The second point to consider is that all abrasive machine polishes leave scratches in the paint. Polish grains (abrasives), in order to work, have to be harder than the paint's surface. As they tumble, rub or slide across the paint, they remove small impressions in the surface (usually 1/3 or less the size of the actual abrasive).

Building further on this, it is important to remember that modern abrasives are both designed to break apart and are extremely fine.

While these charts (below) were originally designed to display the difference between SMAT (super micro abrasive technology/non-diminishing abrasives) and DAT (diminishing abrasive technology) they hold some relevance for this post.

Regardless of the abrasive type used and the type of machine it is applied with, it is important to remember these facts:

- The finer the abrasive, the finer the scratch pattern left behind.

- The finer the scratch pattern, the smoother the surface.

- The smoother the surface, the more the light is reflected accurately.

- The more the light is reflected accurately, the greater the perception of gloss.

Since the abrasives used in polishes have to be harder than paint to work, they have to be engineered to break apart or fracture, as the diminishing abrasive chart above demonstrates.

Non-diminishing abrasives are already "broken apart" and produce an extremely fine scratch pattern immediately.

Diminishing abrasives require some level of friction to fracture apart. However, rubbing a small amount of polish between your fingers will produce more than enough friction to quickly break modern diminishing abrasives apart.

While older, larger silica-based and diatomaceous earth abrasives could require a significant amount of friction to diminish, modern polishes simply do not. Regardless of the machine you use, modern abrasive technology will allow you to break down the abrasives fairly quickly.

Your Pad Plays A Role

Your polishing pad of choice plays a huge role in the finish quality you can achieve. The abrasive imprint left behind on the paint is partially controlled by how much the abrasive pushes into the pad as well as how well the pad's foam wall's squeegee the surface clean and entrap spent- abrasive material/paint residue.

Because an article, much longer than this, could be spent on how pad dynamics affect the polishing process, and the effect of different machines on pad dynamics, we will simply state that "all things being equal" applies to this article. This assumes, for this article, that the pad affects the abrasives identically (in terms of material capture and abrasive imprint).

Rotary vs. DA? What's The REAL Difference?

So far we have established the following:

- Smoother paint reflects more light.

- Modern abrasives will break down with minimal friction.

The main difference between a rotary and a random-orbital, dual-action polisher is the way they move the abrasives across the paint.

Rotary polishers are direct drive, and move the pad in a singular, planing motion across the paint.

Dual-Action Random Orbital polishers move the the pad in an orbital (tiny circles around a central point) motion as well as a spinning motion, creating a curly-q action.

The actions of each machine are illustrated in the diagram below:

Since the goal in creating a better finish boils down to leaving behind a smoother finish, which motion creates a better finish?

The simple answer is neither! All things being equal, both machines will leave similar-sized impressions in the paint, with the main difference being the scratch pattern left behind.

The diagram below shows the microscopic scratch pattern created by a rotary polisher:

The diagram below shows the microscopic scratch pattern created by a dual-action random orbital polisher:

Because the scratch pattern of a dual-action random orbital polisher is dispersed across the paint in seemingly random pattern, it is LESS likely that you will see the scratch pattern.

IF you see a scratch pattern left behind by a rotary polisher, it will usually be in the form a hologram effect.

IF you see a scratch pattern left behind by a dual-action random orbital polisher, it will usually appear in the form of a light haze.

However, our eyes are far less likely to see a haze vs. a defined, uniformed hologram effect.

Which Machine Really Produces A Better Finish Depends On The User!

We have all seen the rotary user, with 20 years experience proudly proclaim that they can achieve a better finish with a rotary polisher.

By the same token, we have seen the guy who can create a perfect finish with a DA struggle with a rotary.

This is because changing the motion in which the machine drives the pad across the paint changes the entire dynamic of polish. Just because you have mastered one, or the other, does not mean you will automatically will be proficient with the other.

Because a dual-action random orbital polisher is less likely to create visible swirl marks and paint damage, it is often thought of as a simpler tool to master. In reality, there are far more dynamics involved with this style of polisher than a rotary, and thus it is more difficult to master.

At the end of the day, the tool you can achieve a better finish with will depend on your experience and comfort with that tool.