togwt

The Old Grey Whistle Test

Nanotechnology coatings

Some of the materials and technologies that have changed detailing forever; Polymer sealants, Detailers clay, Microfiber towels, Nanotechnology coatings, Polishes containing nanotechnology ceramic micro-particulate, diminishing abrasives and Full body vinyl wraps

Probably the greatest impact has come from the use of Nanotechnology coatings, which have completely changed the landscape of the detailing industry. Products like Zaino, Collinite, and etc used to be the best protection available but nanotechnology (AQuartz) or a reactive polymer resin coatings (Opti-Coat™ ) that offer greatly extended durability, scratch resistance and protection from the elements that can be measured in seasons or years, as opposed to others

For many years (twenty plus) my polymer sealant of choice was an acrylic polymer (Klasse) I then converted to a polymer sealant (Zaino) and used it for approx fifteen years, but automotive sealants and coatings have evolved immensely over the last five years or so and have changed paint protection to an inordinate degree

Paint sealants compared to Coatings

Paint sealants are synthetic products designed for long-term paint protection and easy application. They are composed mainly of amino functional polymers, which last longer than any natural wax and are highly resistant to the elements. Synthetic liquid waxes are another way of describing paint sealants. The main benefit of a paint sealant is their durability compared to a wax, polymer-based sealants will last anywhere from 3 to 6 months.

A coating is applied to a clean surface and are capable of 'film build', that is to say a measurable thickness, that surface takes on properties that are virtually identical to hardened glass. It is chemically inert and will not react with the base material. In other words, dirt will not bond to the treated surface, thereby reducing soiling and organic staining. Acid rain and other chemical compounds easily wash off, significantly reducing the hydroscopic nature of surfaces exposed to industrial or environmental pollution.

Paint Surfaces

Automotive paint surfaces are porous and can hold up to a pint of water after washing, so ensure that the surface has been thoroughly dried before the application of a sealent or coating. A paint surface comprise contain microscopic peaks and valleys, much like the profile of a mountain range. These irregularities are known as capillary structures; there may be millions of these defects per square inch. Contaminants such as fine dirt, minerals, and pollutants are drawn into the voids where they are extremely hard to remove.

The filling of the capillary structures with nanoparticles produces a hydrophobic surface. (A hydrophobic surface is one that repels moisture.) In contrast, a hydrophilic surface is one that absorbs moisture. The potential of a surface to absorb or repel moisture is based on many factors, including: temperature, relative humidity, material homogeneity, and static electricity. Surface roughness is also a major factor; the rougher the surface, the higher the spreading rate or attraction for water. The smoother the surface, the more repellent it is to moisture.

The significance of a nano-coating is its small particle size that can form a very tight bond with the surface of most materials; including glass, paint, plastic, rubber, aluminium, chrome, stainless steel and fabrics, will have surface imperfections i.e. micro-fissures when viewed under high magnification. These undulations allow a nano-coating polymer to form a tight molecular bond (much like a printers ink when poured over paper that has writing indentations on it) with the surface it’s applied to This level surface also improves paint surface clarity and reduce light scattering, providing improved light reflectance

What is Nanotechnology as it relates to Detailing?

The science of nanotechnology; the creation, organization, or manipulation of materials, devices, or systems at the nanometre level Nanotechnology, Nano particles or Nano structures, exactly what are they and how do they relate to detailing?

Most of these coatings are based around super siloxanes, and not true nanotube/tubule technology. This would cause a serious health concern for all of those - not to mention be ridiculously expensive. The context that “nano" (as related to detailing) is only as a relative size indicator merely to identify a siloxane/polymer.

They are sub micron particles that form a clear thin film of tightly packed nano particles forming an extension of the surface. The particles are up to a 1000 times denser which makes for an ultra durable hard wearing surface.

Technically most detailing product particulates are not nano metre in size, although they are extremely small, as the term ‘nano’ adequately describes. Single-component coatings interlace on a molecular basis and form an extremely durable protective layer on the paint surface provided they are applied properly.

The significance of a nano-coating is its micro sized particles that can form a very tight bond with the surface of most materials; including glass, paint, plastic, rubber, aluminium, chrome, stainless steel and fabrics. These materials will have surface imperfections i.e. peaks and valleys, micro-fissures when viewed under high magnification.

These undulations allow a nano-coating polymer to form a tight molecular bond (much like a printer’s powdered ink when poured over paper that has writing indentations on it) with the surface it’s applied to.

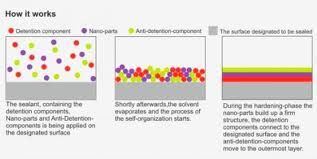

Formation of a Nano Structure

Sealing a surface with nanotechnology means applying nano-structures onto the surface, these treated surfaces become hydrophobic and resists road dirt, grime and etc attaching to its surface by the ‘Lotus Effect’. It is therefore highly water repellent, which enables less effort during the cleaning stages and optimum protection to the paintwork, glass, alloys, fabric and trim.

Nanotechnology coatings form a very tight matrix chain-link a nano structure that comprises a clear thin film of tightly packed nano particles forming an extension of the surface. These very dense particles are both a very strong bond and one that is not easily breached by chemicals or detergents. They also improve paint surface clarity and reduce light scattering, providing improved light reflectance

Through self-organizing anti adhesion components, the nanostructure forms an invisible barrier similar to glass. They form a bond by lodging themselves into the micro pores of the paint forming an anchored foundation and then this foundation is built upon to form the nano particle matrix.

This is why a clean, dry and oil-free (micro pore) surface is so important. Only the nanostructure remains on the sealed surfaces, while the water evaporates.

Nanotechnology offers superior durability, hydrophobicity, surface hardness and scratch resistance, resistance to environmental contaminants, works like a clear coat in providing ultra violet (UV) and heat radiation protection without colour change (yellowing) or oxidation and easier maintenance, simply rinsing with plain water results in a clean surface without loss of gloss. I think these products will have a profound impact and radically change auto detailing

Paint Surface Preparation (nanotechnology coatings)

The surface cleaning process is absolutely crucial in order to achieve long lasting results. The cleaner your cars’ paint is before the coating is applied, the longer the protective layer will last.

Prepare the paint surface to your personal level of perfection (washed, clayed, decontaminated, polished and an isopropyl alcohol wipe-down process) Polish the paint surface to remove any surface scratches as this product will highlight them

The solvent in most paint protection products (coatings being the exception) will actually displace waxes and oils, allowing the product to bond with the paint surface and cross-link (polymers) or cure (waxes).

However prior to the application of a paint protection coating it is absolutely necessary to remove any (mostly invisible to the naked eye) fillers, oils and other residue, if they are allowed to remain a white or grey hazing will appear on the paint surface once the coating is applied.

Gtechniq Panel Wipe – removes surface residue (silicone, surfactants, oil, wax and polish lubrication residue) allowing a ‘clean’ surface prior to the application of a coating product to effectively form a chemical bonds. Panel Wipe blend pure alcohols with aromatic solvents to dissolve any polish residues and 'flash' off, to leave a completely ‘cleaned’ surface prior to the application of a coating paint protection product.

#Nanotechnology Coating products

1. AQuartz is an inorganic silica / silicon dioxide

2. G|techniq is an inorganic silicate crystallization compound

3. Nanolex is an inorganic, solvent-based nanostructure coating

4. DuPont's SupraShield™, PPG's Optech™ and CeramiClear™ are all inorganic silica coating

Bibliography

1. Royal Society of Chemistry (RSC) Library & Information Centre

2. Glossary of Chemical Terms - Faculty of Chemical Technology

3. Basic Concepts of Nanotechnology, History of Nano-Technology, News, Materials and Potential Risks

4. Lotus-inspired nanotechnology applications, B. Karthick1 and Ramesh Maheshwari

5. SpecialChem4 Polymers

6. Macromolecular Chemistry and Physics

7. European Coatings Handbook 2nd Edition, by Brock, Groteklaes, Mischke

8. Bayer Material Science, Automotive eNewsletters (Coating, Adhesives and Specialties)

The information in this article is based on the current status of the technical development as well as our experience with the product.

[Edit: General revision and updates 02.26.13]

Some of the materials and technologies that have changed detailing forever; Polymer sealants, Detailers clay, Microfiber towels, Nanotechnology coatings, Polishes containing nanotechnology ceramic micro-particulate, diminishing abrasives and Full body vinyl wraps

Probably the greatest impact has come from the use of Nanotechnology coatings, which have completely changed the landscape of the detailing industry. Products like Zaino, Collinite, and etc used to be the best protection available but nanotechnology (AQuartz) or a reactive polymer resin coatings (Opti-Coat™ ) that offer greatly extended durability, scratch resistance and protection from the elements that can be measured in seasons or years, as opposed to others

For many years (twenty plus) my polymer sealant of choice was an acrylic polymer (Klasse) I then converted to a polymer sealant (Zaino) and used it for approx fifteen years, but automotive sealants and coatings have evolved immensely over the last five years or so and have changed paint protection to an inordinate degree

Paint sealants compared to Coatings

Paint sealants are synthetic products designed for long-term paint protection and easy application. They are composed mainly of amino functional polymers, which last longer than any natural wax and are highly resistant to the elements. Synthetic liquid waxes are another way of describing paint sealants. The main benefit of a paint sealant is their durability compared to a wax, polymer-based sealants will last anywhere from 3 to 6 months.

A coating is applied to a clean surface and are capable of 'film build', that is to say a measurable thickness, that surface takes on properties that are virtually identical to hardened glass. It is chemically inert and will not react with the base material. In other words, dirt will not bond to the treated surface, thereby reducing soiling and organic staining. Acid rain and other chemical compounds easily wash off, significantly reducing the hydroscopic nature of surfaces exposed to industrial or environmental pollution.

Paint Surfaces

Automotive paint surfaces are porous and can hold up to a pint of water after washing, so ensure that the surface has been thoroughly dried before the application of a sealent or coating. A paint surface comprise contain microscopic peaks and valleys, much like the profile of a mountain range. These irregularities are known as capillary structures; there may be millions of these defects per square inch. Contaminants such as fine dirt, minerals, and pollutants are drawn into the voids where they are extremely hard to remove.

The filling of the capillary structures with nanoparticles produces a hydrophobic surface. (A hydrophobic surface is one that repels moisture.) In contrast, a hydrophilic surface is one that absorbs moisture. The potential of a surface to absorb or repel moisture is based on many factors, including: temperature, relative humidity, material homogeneity, and static electricity. Surface roughness is also a major factor; the rougher the surface, the higher the spreading rate or attraction for water. The smoother the surface, the more repellent it is to moisture.

The significance of a nano-coating is its small particle size that can form a very tight bond with the surface of most materials; including glass, paint, plastic, rubber, aluminium, chrome, stainless steel and fabrics, will have surface imperfections i.e. micro-fissures when viewed under high magnification. These undulations allow a nano-coating polymer to form a tight molecular bond (much like a printers ink when poured over paper that has writing indentations on it) with the surface it’s applied to This level surface also improves paint surface clarity and reduce light scattering, providing improved light reflectance

What is Nanotechnology as it relates to Detailing?

The science of nanotechnology; the creation, organization, or manipulation of materials, devices, or systems at the nanometre level Nanotechnology, Nano particles or Nano structures, exactly what are they and how do they relate to detailing?

Most of these coatings are based around super siloxanes, and not true nanotube/tubule technology. This would cause a serious health concern for all of those - not to mention be ridiculously expensive. The context that “nano" (as related to detailing) is only as a relative size indicator merely to identify a siloxane/polymer.

They are sub micron particles that form a clear thin film of tightly packed nano particles forming an extension of the surface. The particles are up to a 1000 times denser which makes for an ultra durable hard wearing surface.

Technically most detailing product particulates are not nano metre in size, although they are extremely small, as the term ‘nano’ adequately describes. Single-component coatings interlace on a molecular basis and form an extremely durable protective layer on the paint surface provided they are applied properly.

The significance of a nano-coating is its micro sized particles that can form a very tight bond with the surface of most materials; including glass, paint, plastic, rubber, aluminium, chrome, stainless steel and fabrics. These materials will have surface imperfections i.e. peaks and valleys, micro-fissures when viewed under high magnification.

These undulations allow a nano-coating polymer to form a tight molecular bond (much like a printer’s powdered ink when poured over paper that has writing indentations on it) with the surface it’s applied to.

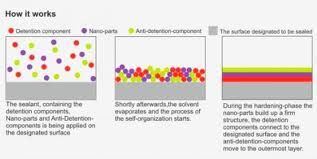

Formation of a Nano Structure

Sealing a surface with nanotechnology means applying nano-structures onto the surface, these treated surfaces become hydrophobic and resists road dirt, grime and etc attaching to its surface by the ‘Lotus Effect’. It is therefore highly water repellent, which enables less effort during the cleaning stages and optimum protection to the paintwork, glass, alloys, fabric and trim.

Nanotechnology coatings form a very tight matrix chain-link a nano structure that comprises a clear thin film of tightly packed nano particles forming an extension of the surface. These very dense particles are both a very strong bond and one that is not easily breached by chemicals or detergents. They also improve paint surface clarity and reduce light scattering, providing improved light reflectance

Through self-organizing anti adhesion components, the nanostructure forms an invisible barrier similar to glass. They form a bond by lodging themselves into the micro pores of the paint forming an anchored foundation and then this foundation is built upon to form the nano particle matrix.

This is why a clean, dry and oil-free (micro pore) surface is so important. Only the nanostructure remains on the sealed surfaces, while the water evaporates.

Nanotechnology offers superior durability, hydrophobicity, surface hardness and scratch resistance, resistance to environmental contaminants, works like a clear coat in providing ultra violet (UV) and heat radiation protection without colour change (yellowing) or oxidation and easier maintenance, simply rinsing with plain water results in a clean surface without loss of gloss. I think these products will have a profound impact and radically change auto detailing

Paint Surface Preparation (nanotechnology coatings)

The surface cleaning process is absolutely crucial in order to achieve long lasting results. The cleaner your cars’ paint is before the coating is applied, the longer the protective layer will last.

Prepare the paint surface to your personal level of perfection (washed, clayed, decontaminated, polished and an isopropyl alcohol wipe-down process) Polish the paint surface to remove any surface scratches as this product will highlight them

The solvent in most paint protection products (coatings being the exception) will actually displace waxes and oils, allowing the product to bond with the paint surface and cross-link (polymers) or cure (waxes).

However prior to the application of a paint protection coating it is absolutely necessary to remove any (mostly invisible to the naked eye) fillers, oils and other residue, if they are allowed to remain a white or grey hazing will appear on the paint surface once the coating is applied.

Gtechniq Panel Wipe – removes surface residue (silicone, surfactants, oil, wax and polish lubrication residue) allowing a ‘clean’ surface prior to the application of a coating product to effectively form a chemical bonds. Panel Wipe blend pure alcohols with aromatic solvents to dissolve any polish residues and 'flash' off, to leave a completely ‘cleaned’ surface prior to the application of a coating paint protection product.

#Nanotechnology Coating products

1. AQuartz is an inorganic silica / silicon dioxide

2. G|techniq is an inorganic silicate crystallization compound

3. Nanolex is an inorganic, solvent-based nanostructure coating

4. DuPont's SupraShield™, PPG's Optech™ and CeramiClear™ are all inorganic silica coating

Bibliography

1. Royal Society of Chemistry (RSC) Library & Information Centre

2. Glossary of Chemical Terms - Faculty of Chemical Technology

3. Basic Concepts of Nanotechnology, History of Nano-Technology, News, Materials and Potential Risks

4. Lotus-inspired nanotechnology applications, B. Karthick1 and Ramesh Maheshwari

5. SpecialChem4 Polymers

6. Macromolecular Chemistry and Physics

7. European Coatings Handbook 2nd Edition, by Brock, Groteklaes, Mischke

8. Bayer Material Science, Automotive eNewsletters (Coating, Adhesives and Specialties)

The information in this article is based on the current status of the technical development as well as our experience with the product.

[Edit: General revision and updates 02.26.13]