Todd@RUPES

Just a regular guy

Leave swirls in the past with the latest in polishing technology!

Optimum Polymer Technologies is a small company that has been making big waves in the detailing industry since 2001. Based out of Memphis, Tennessee, Optimum Polymer Technologies was founded by Dr. David Ghodoussi, the former paint polymer chemist for PPG. Optimum Polymer Technologies' motto is “Accelerate Into The Future” and the continuous advancements Optimum puts into each new have kept to that statement.

Optimum new's polishing system, the Optimum Hyper Micro System, combines several cutting technologies to make your machine polishing results easier while producing perfect results. The Optimum Hyper Micro System combines several new and cutting edge technologies to accelerate your polishing into the future.

Advancements:

Polishes utilize spray technology to deliver an uniform amount of polish to the pad

Latest in microfiber pad technology for dual-action and rotary style buffers

Compound uses the latest in refined aluminum oxide “non-diminishing abrasives”

Polish uses the latest in refined aluminum oxide “diminishing abrasives”

The results of these technologies is a two step paint correction system that gives the dual-action polisher almost as much paint polishing power as a rotary polisher, while creating a flawless result, even on soft black finishes.

The Optimum Polymer Technologies Hyper Micro System includes Optimum Hyper Compound Spray, Optimum Hyper Polish Spray, Optimum Microfiber Compounding Pad, and the Optimum Microfiber Polishing Pad.

The Test Panel:

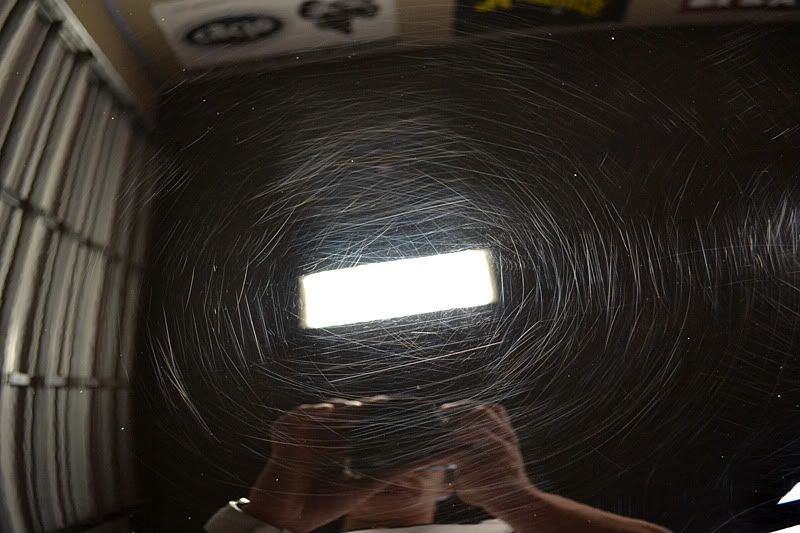

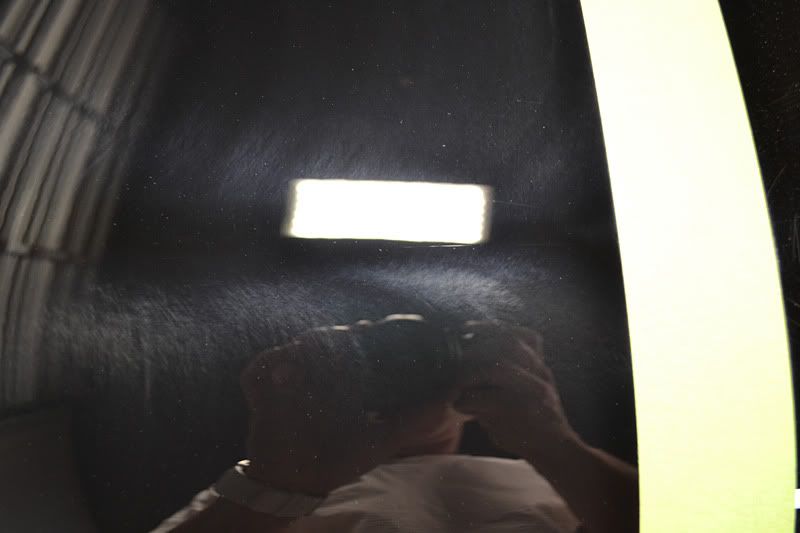

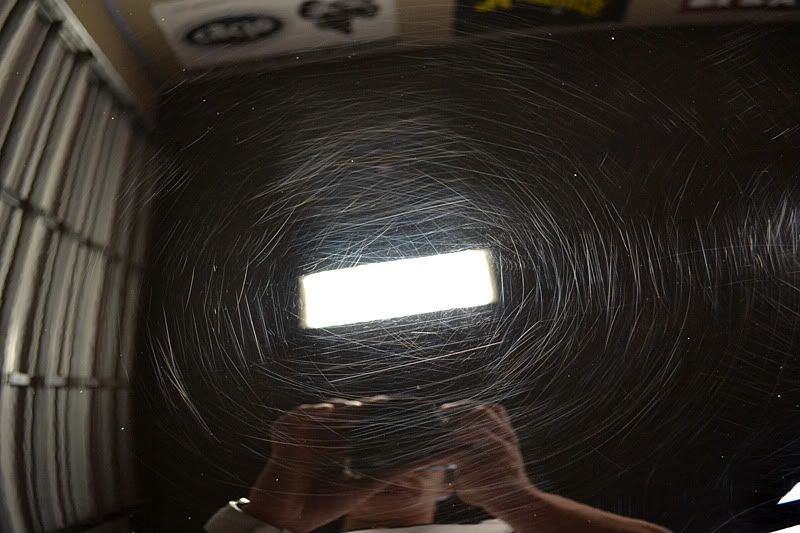

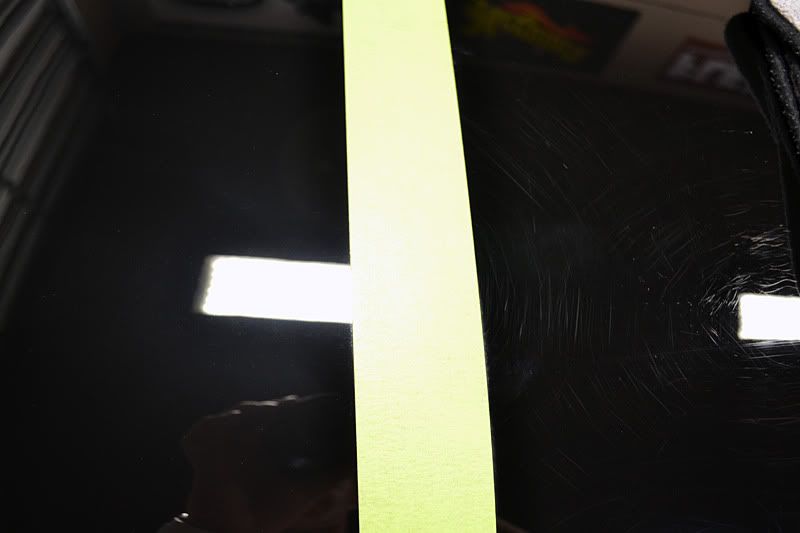

This trunk lid has been sprayed with extremely soft base coat / clear coat in black. This allows us to test products to the extreme an analyze their performance accurately. I created swirl marks in the paint by rubbing a stiff bristled brush over the finish. The result was deeper swirl marks that are far worse then what you would find on your typical daily driver (unless you have been washing your car with a stiff brush!).

The marks were so deep that they were easily visible under fluorescent lighting.

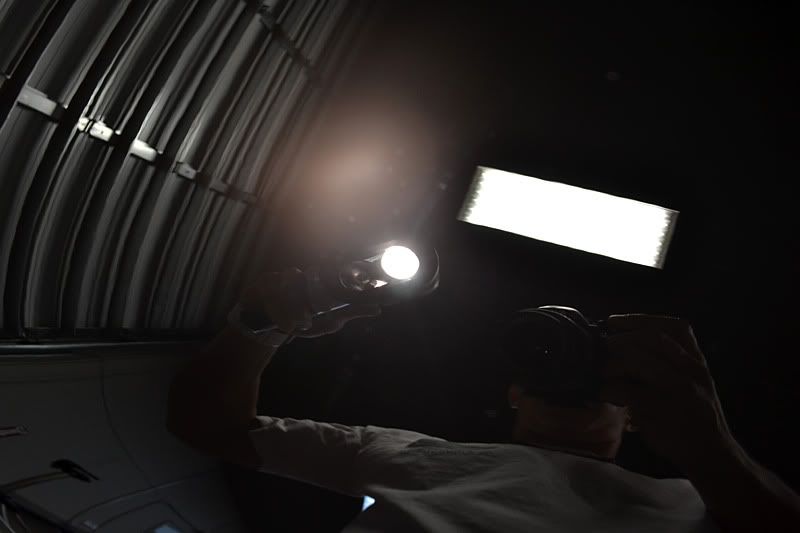

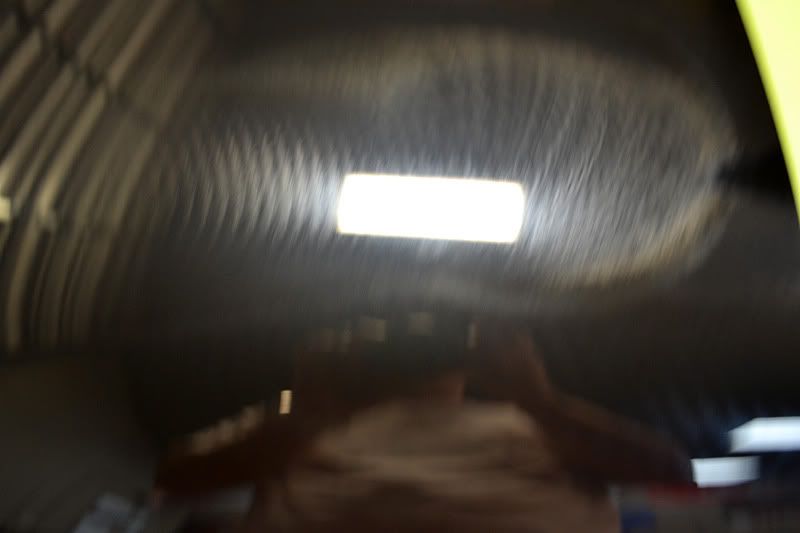

Igniting the paint with a Brinkmann Swirl Finder light showed how truly bad it was.

Step One: Optimum Hyper Compound Spray & Optimum Microfiber Compounding Pad

Optimum Hyper Compound Spray is a unique spray on formula originally designed for OEM (factory) application to provide fast repair of paint defects while minimizing paint product waste. This cutting edge Compound uses several advancements in paint polishing technologies, including a very unique abrasive that maintains an even amount of cutting power through out the polishing cycle. This gives Optimum Hyper Compound Spray the ability to remove paint defects quickly, even when used with a dual-action polisher, while maintaining a high a high gloss finish that only requires minimal final polishing for a flawless finish.

The Optimum Microfiber Compounding Pad uses the latest technologies that utilizes the orbital action of a DA polisher to give it cutting power that is near rotary level while maintaining the safety and ease-of-use that dual action polisher users have come to expect. The combination of these two products gives the user a safe way to correct serious paint defects.

Start by centering the Optimum Microfiber Compounding Pad on the backing plate. For this test I am using the Porter Cable 7424 XP random orbital polisher.

Apply Optimum Hyper Compound Spray Polish to the pad by holding it approximately 6 inches away and squeezing the trigger quickly. For fresh, dry pads, use two sprays. Once the pad is primed, use only one spray for an additional section.

The compound is evenly dispersed onto the pad's surface.

The same principals of machine polishing apply to using this cutting edge system. Drape the cord over your shoulder and hold the machine comfortably. Work a section at a time, approximately 2' x 2'. If you need more cutting power you can shrink the work section down. Polish on speed 5 or 6, using firm pressure (enough to slow the rotation of the towel but not enough to stall it completely) and move your arms in over lapping passes.

Here is the one exception, with most polishes and compounds, you work until the polish “break's down.” In the case of Optimum Hyper Compound, you work until the defects are the removed. That is because the advanced “non-diminishing abrasives” will continue to work as long as they are applied.

Work a 2' x 2' section with firm pressure on speed 5 or 6, with slow arm speed and firm pressure in overlapping passes.

Optimum Hyper Compound has an incredibly long work time, work until you can no longer see defects or the compound becomes clear.

Buff of the residue with a soft microfiber towel, such as a Supreme 530. Hyper Com pond buffs off with incredible ease.

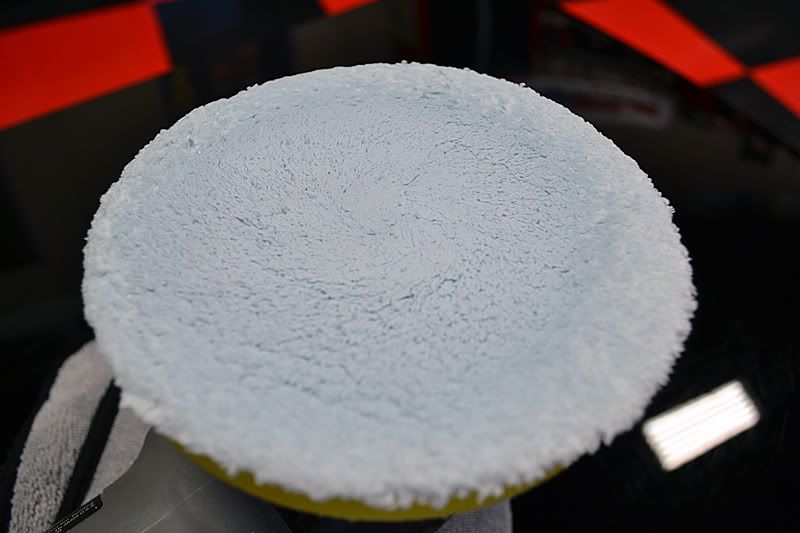

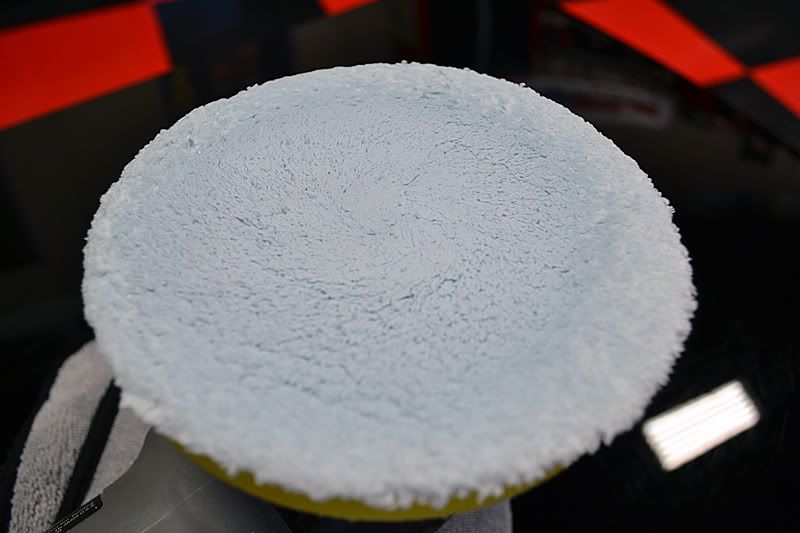

Microfiber Polishing Pad's Quick Tip: As you polish with any microfiber pad the nap will become flat and pressed down. This changes the dynamic of the pad and significantly reduces cutting ability. To keep the pads clean (for the best finish) and keep them fluffed (for the best cut) it is important to clean your pads frequently. The best way to clean them is to blow them clean with an air squirter attached to an air compressor. If you don't have access to this, use a nylon bristled pad brush.

The fibers have become matted down.

Run the machine while pressing a nylon pad conditioning brush into the nap.

The pad is now fluffed and clean and great for additional product (and the next section).

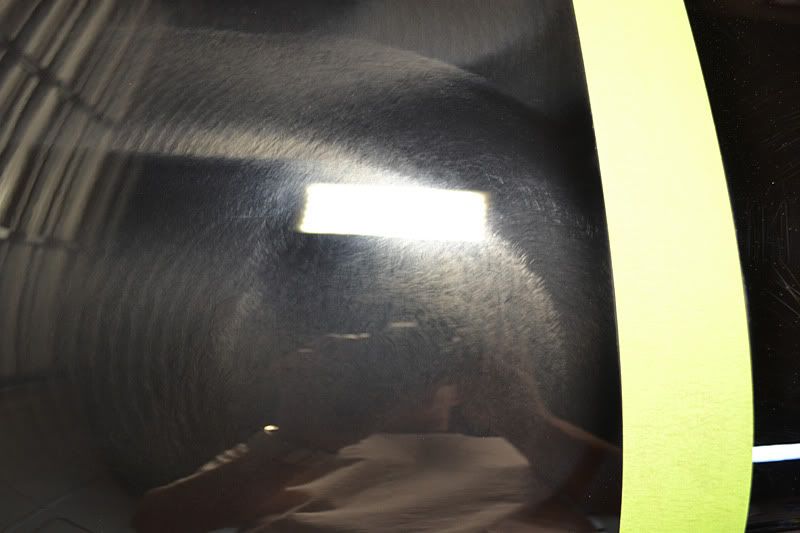

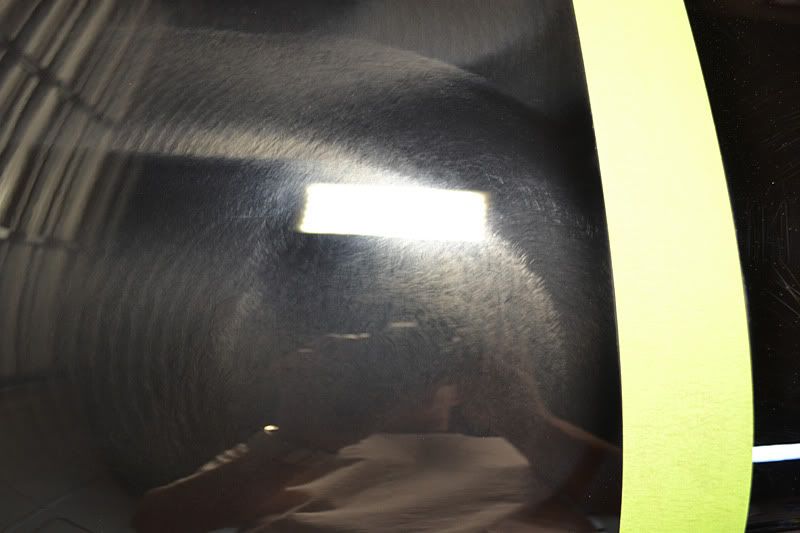

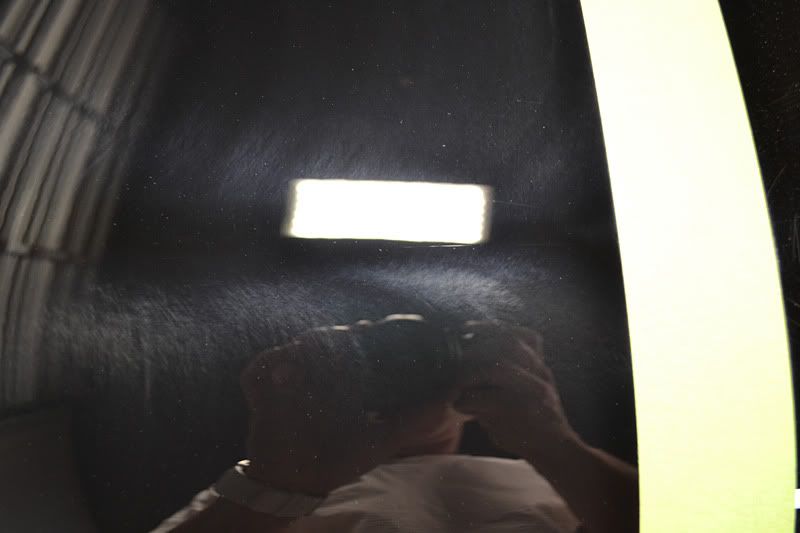

One of the benefits of both the advanced Microfiber pads and the Hyper Compound is both leave a very nice finish (for a compound). There is very faint haze in the paint at this point (which is incredible considering how soft the paint on the test panel is).

Here is the before side...

After compounding (not final polishing)...

And a 50/50 split shot....

Step Two: Optimum Hyper Polish Spray & Optimum Microfiber Polishing Pad

Optimum Hyper Polish Spray is a unique spray application polish that uses ultra refined diminishing abrasives to burnish the paint to a high-gloss shine. Just like all Optimum polishes, Optimum Hyper Polish is extremely easy to use and has a long working time with no dusting or sling issues. Its spray application minimizes the chance of overloading or gumming up the pad, and it provides an even application. Optimum Hyper Polish easily wipes off with a damp microfiber towel, whether you use it in the sun or shade, to achieve outstanding results.

The Optimum Microfiber Polishing Pad uses the latest technologies that utilize the orbital action of a DA polisher to give it good polishing power while maintaining the safety and ease-of-use that dual action polisher users have come to expect. The combination of these two products gives the user a safe way quickly and easily remove light defects and create a stunning, flawless finish.

Start by centering the Microfiber Polishing Pad to the backing plate of your DA polisher. Mist Optimum Hyper Polish Spray onto the Optimum Microfiber Polishing Pad in the same fashion you did with the compound. Use two sprays to prime a pad for initial use and one spray per section after that.

The same principals of machine polishing apply to using this cutting edge system. Drape the cord over your shoulder and hold the machine comfortably. Work a section at a time, approximately 2' x 2'. If you need more cutting power you can shrink the work section down. Polish on speed 5 or 6, using firm pressure (enough to slow the rotation of the towel but not enough to stall it completely) and move your arms in over lapping passes.

Optimum Hyper Polish Spray uses traditional like abrasives that do break down, so continuing working until the polish appears to 'clear' on the paint surface. At this point reduce to speed 4 and continue working for an additional pass maintaining firm pressure. Then buff away residue to reveal a high-gloss, swirl-free shine.

Optimum Hyper Spray Polish uses a diminishing abrasive that will achieve best results when broken down. Here is the film on the paint when it is fresh.

Work in smooth, overlapping passes, until the polish breaks down (becomes clear).

At this point, with the polish nearly translucent, the polish is ready to be removed with a soft microfiber cloth. That's it, your done. Having a flawless finish can be that easy!

Optimum Polymer Technologies is a small company that has been making big waves in the detailing industry since 2001. Based out of Memphis, Tennessee, Optimum Polymer Technologies was founded by Dr. David Ghodoussi, the former paint polymer chemist for PPG. Optimum Polymer Technologies' motto is “Accelerate Into The Future” and the continuous advancements Optimum puts into each new have kept to that statement.

Optimum new's polishing system, the Optimum Hyper Micro System, combines several cutting technologies to make your machine polishing results easier while producing perfect results. The Optimum Hyper Micro System combines several new and cutting edge technologies to accelerate your polishing into the future.

Advancements:

Polishes utilize spray technology to deliver an uniform amount of polish to the pad

Latest in microfiber pad technology for dual-action and rotary style buffers

Compound uses the latest in refined aluminum oxide “non-diminishing abrasives”

Polish uses the latest in refined aluminum oxide “diminishing abrasives”

The results of these technologies is a two step paint correction system that gives the dual-action polisher almost as much paint polishing power as a rotary polisher, while creating a flawless result, even on soft black finishes.

The Optimum Polymer Technologies Hyper Micro System includes Optimum Hyper Compound Spray, Optimum Hyper Polish Spray, Optimum Microfiber Compounding Pad, and the Optimum Microfiber Polishing Pad.

The Test Panel:

This trunk lid has been sprayed with extremely soft base coat / clear coat in black. This allows us to test products to the extreme an analyze their performance accurately. I created swirl marks in the paint by rubbing a stiff bristled brush over the finish. The result was deeper swirl marks that are far worse then what you would find on your typical daily driver (unless you have been washing your car with a stiff brush!).

The marks were so deep that they were easily visible under fluorescent lighting.

Igniting the paint with a Brinkmann Swirl Finder light showed how truly bad it was.

Step One: Optimum Hyper Compound Spray & Optimum Microfiber Compounding Pad

Optimum Hyper Compound Spray is a unique spray on formula originally designed for OEM (factory) application to provide fast repair of paint defects while minimizing paint product waste. This cutting edge Compound uses several advancements in paint polishing technologies, including a very unique abrasive that maintains an even amount of cutting power through out the polishing cycle. This gives Optimum Hyper Compound Spray the ability to remove paint defects quickly, even when used with a dual-action polisher, while maintaining a high a high gloss finish that only requires minimal final polishing for a flawless finish.

The Optimum Microfiber Compounding Pad uses the latest technologies that utilizes the orbital action of a DA polisher to give it cutting power that is near rotary level while maintaining the safety and ease-of-use that dual action polisher users have come to expect. The combination of these two products gives the user a safe way to correct serious paint defects.

Start by centering the Optimum Microfiber Compounding Pad on the backing plate. For this test I am using the Porter Cable 7424 XP random orbital polisher.

Apply Optimum Hyper Compound Spray Polish to the pad by holding it approximately 6 inches away and squeezing the trigger quickly. For fresh, dry pads, use two sprays. Once the pad is primed, use only one spray for an additional section.

The compound is evenly dispersed onto the pad's surface.

The same principals of machine polishing apply to using this cutting edge system. Drape the cord over your shoulder and hold the machine comfortably. Work a section at a time, approximately 2' x 2'. If you need more cutting power you can shrink the work section down. Polish on speed 5 or 6, using firm pressure (enough to slow the rotation of the towel but not enough to stall it completely) and move your arms in over lapping passes.

Here is the one exception, with most polishes and compounds, you work until the polish “break's down.” In the case of Optimum Hyper Compound, you work until the defects are the removed. That is because the advanced “non-diminishing abrasives” will continue to work as long as they are applied.

Work a 2' x 2' section with firm pressure on speed 5 or 6, with slow arm speed and firm pressure in overlapping passes.

Optimum Hyper Compound has an incredibly long work time, work until you can no longer see defects or the compound becomes clear.

Buff of the residue with a soft microfiber towel, such as a Supreme 530. Hyper Com pond buffs off with incredible ease.

Microfiber Polishing Pad's Quick Tip: As you polish with any microfiber pad the nap will become flat and pressed down. This changes the dynamic of the pad and significantly reduces cutting ability. To keep the pads clean (for the best finish) and keep them fluffed (for the best cut) it is important to clean your pads frequently. The best way to clean them is to blow them clean with an air squirter attached to an air compressor. If you don't have access to this, use a nylon bristled pad brush.

The fibers have become matted down.

Run the machine while pressing a nylon pad conditioning brush into the nap.

The pad is now fluffed and clean and great for additional product (and the next section).

One of the benefits of both the advanced Microfiber pads and the Hyper Compound is both leave a very nice finish (for a compound). There is very faint haze in the paint at this point (which is incredible considering how soft the paint on the test panel is).

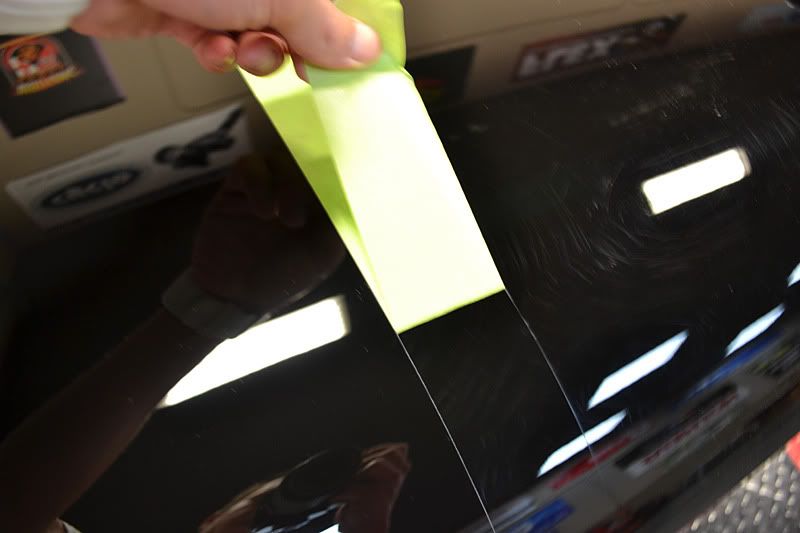

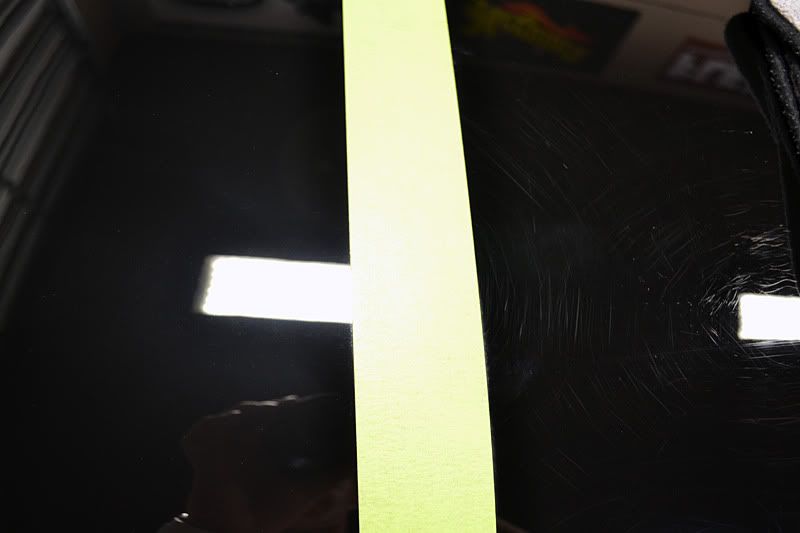

Here is the before side...

After compounding (not final polishing)...

And a 50/50 split shot....

Step Two: Optimum Hyper Polish Spray & Optimum Microfiber Polishing Pad

Optimum Hyper Polish Spray is a unique spray application polish that uses ultra refined diminishing abrasives to burnish the paint to a high-gloss shine. Just like all Optimum polishes, Optimum Hyper Polish is extremely easy to use and has a long working time with no dusting or sling issues. Its spray application minimizes the chance of overloading or gumming up the pad, and it provides an even application. Optimum Hyper Polish easily wipes off with a damp microfiber towel, whether you use it in the sun or shade, to achieve outstanding results.

The Optimum Microfiber Polishing Pad uses the latest technologies that utilize the orbital action of a DA polisher to give it good polishing power while maintaining the safety and ease-of-use that dual action polisher users have come to expect. The combination of these two products gives the user a safe way quickly and easily remove light defects and create a stunning, flawless finish.

Start by centering the Microfiber Polishing Pad to the backing plate of your DA polisher. Mist Optimum Hyper Polish Spray onto the Optimum Microfiber Polishing Pad in the same fashion you did with the compound. Use two sprays to prime a pad for initial use and one spray per section after that.

The same principals of machine polishing apply to using this cutting edge system. Drape the cord over your shoulder and hold the machine comfortably. Work a section at a time, approximately 2' x 2'. If you need more cutting power you can shrink the work section down. Polish on speed 5 or 6, using firm pressure (enough to slow the rotation of the towel but not enough to stall it completely) and move your arms in over lapping passes.

Optimum Hyper Polish Spray uses traditional like abrasives that do break down, so continuing working until the polish appears to 'clear' on the paint surface. At this point reduce to speed 4 and continue working for an additional pass maintaining firm pressure. Then buff away residue to reveal a high-gloss, swirl-free shine.

Optimum Hyper Spray Polish uses a diminishing abrasive that will achieve best results when broken down. Here is the film on the paint when it is fresh.

Work in smooth, overlapping passes, until the polish breaks down (becomes clear).

At this point, with the polish nearly translucent, the polish is ready to be removed with a soft microfiber cloth. That's it, your done. Having a flawless finish can be that easy!