imported_DetailDan

New member

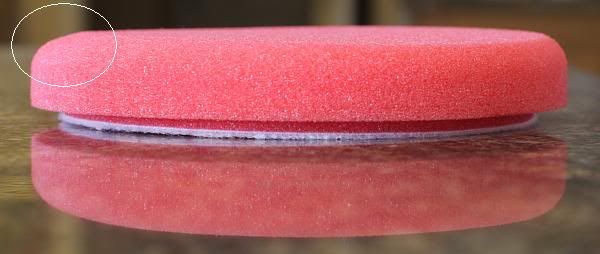

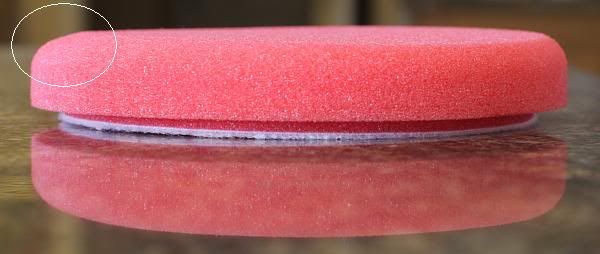

I got some of the thin 5.5" hydro tech pads (cyan, tangerine, and crimson). However, one of my crimson pads was cut weird so I sent it back. I just got the new one and it is cut weird as well. So I was wondering if this is normal or not? I attached some pictures so you can see what I'm referring to.