Greg Gellas

I'm Greg :)

Ok, I didn't smear anything, I properly prepped and applied Cquartz.

I reached out to a request for a Cquartz coating job. It was a brand new BMW 535 with 1000 miles on it. After a quick trip down to Princeton New Jersey for a visual inspection, I had a better idea of what I was in for. Luckily for me the owner was knowledgable enough not to wash the car in a swirl-o-matic, possibly inducing swirls and marring the paint, causing more work to be done. He left it dirty for me. I know it sounds weird but I appreciated that the car was left dirty before I got my hands on it. It really does make my life easier.

I began by cleaning the wheels using Sonax FE, Ez-Detail Brushes, and a DI Boars hair brush for the lug nuts. Why did I do the wheels first, so I wasn't sitting in water doing them after I washed the car. I knew it would get a second washing.

After finishing the wheels, I pre-treated the lower panels with IronX, then gave it a good wash using Ironx Soap Gel in my foam gun.

Since it was sunny out, I quickly brought the car inside to dry it. After dried I clayed the entire car. There wasn't much contamination for the bar to pick up, but it is a critical step when doing a coating. Thorough checking of the paint is always important to ensure you catch all of the imperfections.

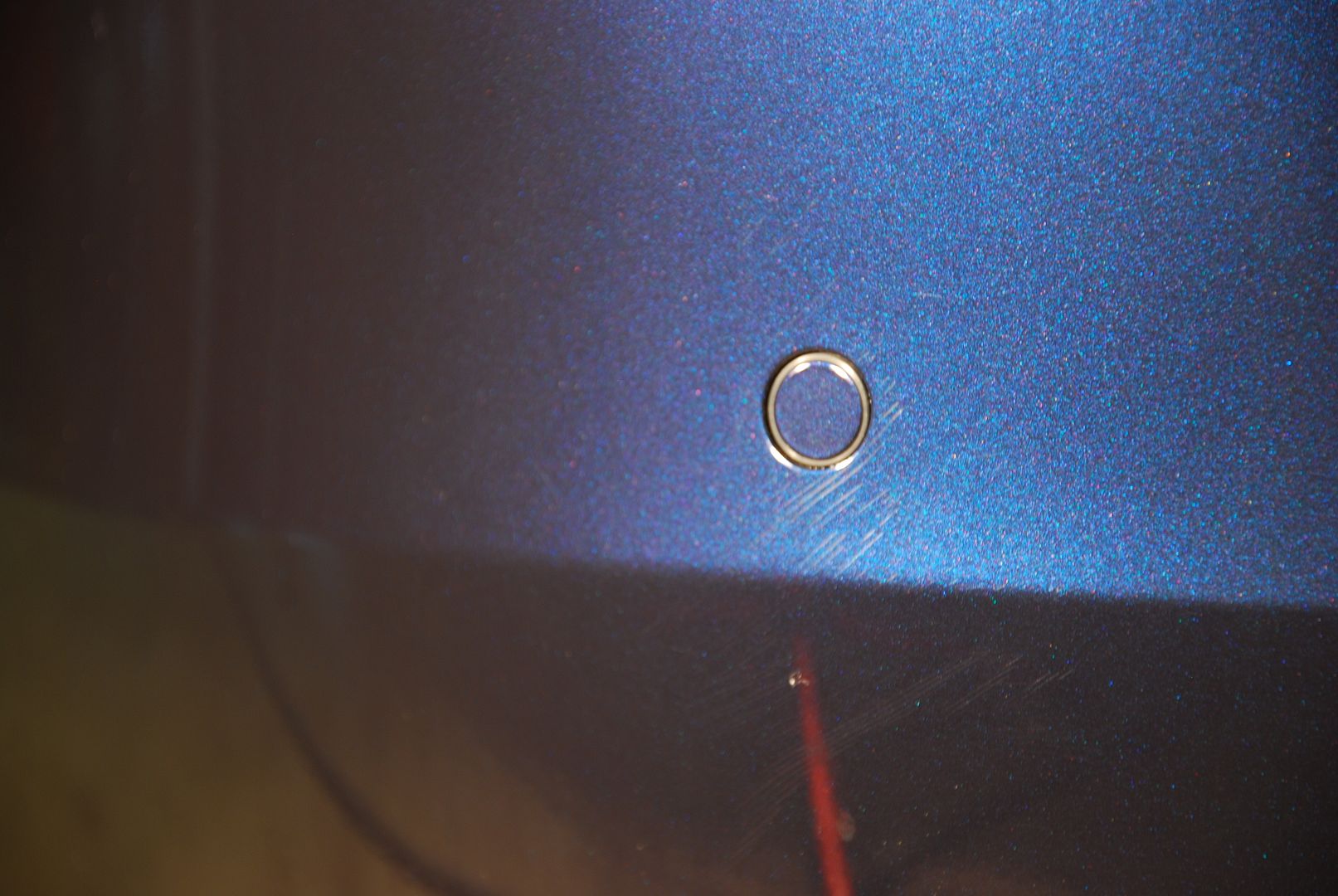

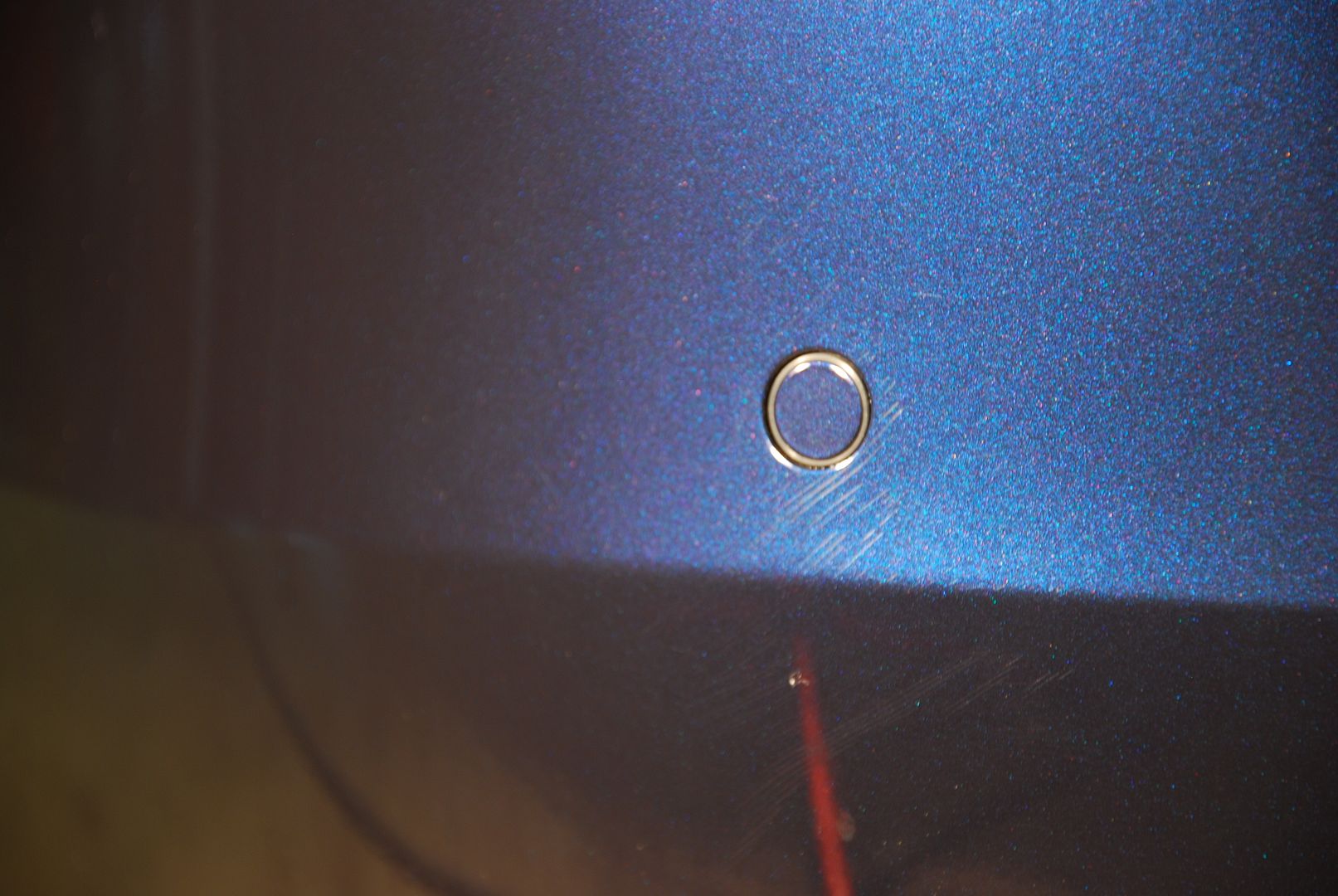

Even though it is a new car it still had some issues that needed correction before coating the paint. I found one area in particular that had fairly excessive damage to the paint. I was able to correct this area using Meg's MF pads and D300. They corrected out really well.

There were some random scrapes on the paint throughout the car, nothing bad, but correction was needed.

I followed up with every inch of the paint getting polished with Menzerna 85RD to ensure I maximized the gloss in the factory clear.

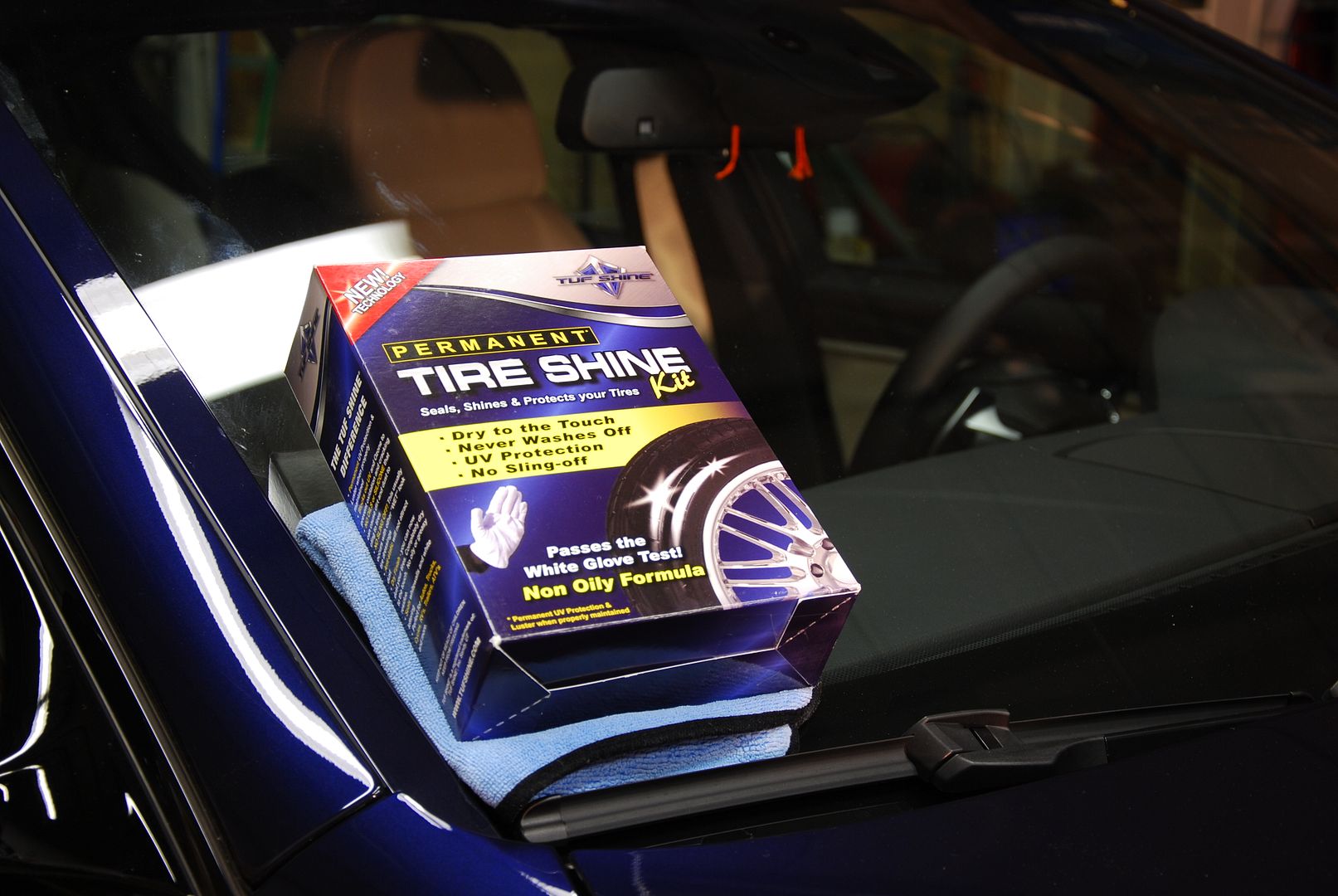

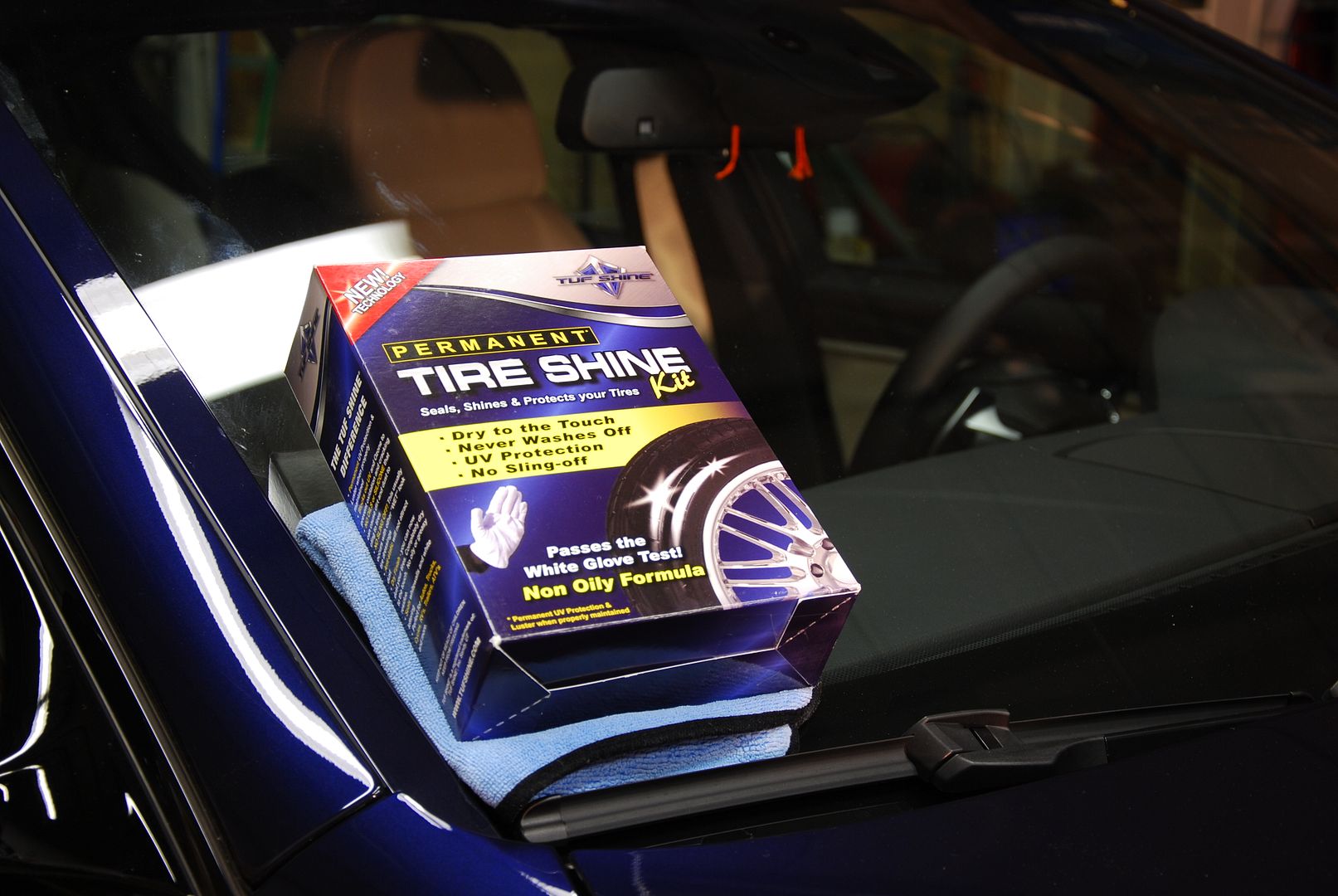

The car also got the Tuff shine semi-permanent tire dressing applied. This is a two step process starting with their cleaning spray, and once the tires are dry apply their tire "clearcoat". This leaves the tires with a nice semi-permanent matte finish.

You can see the cleaner doing its job. I cleaned the tires three times until I no longer got any dirt from the tires.

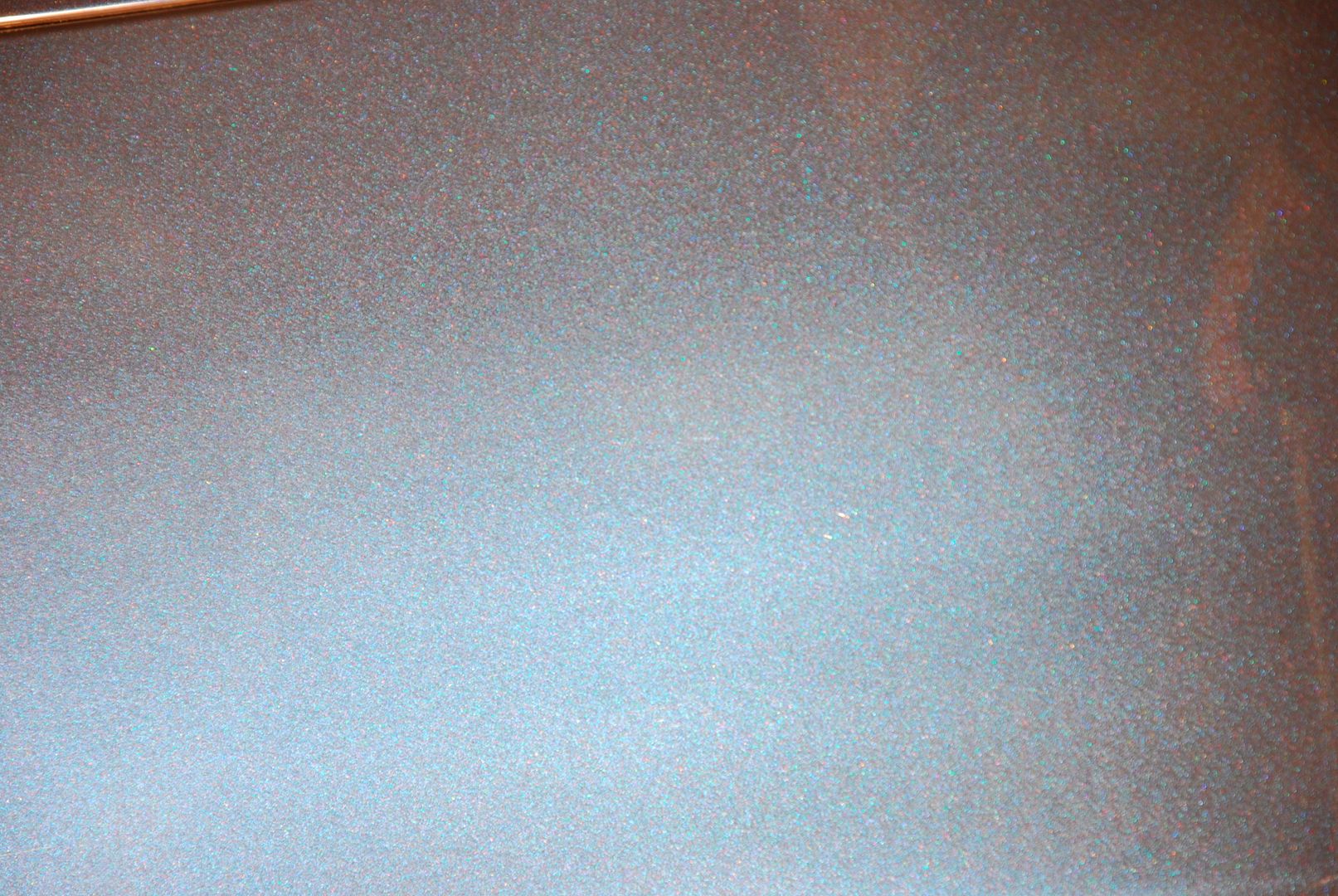

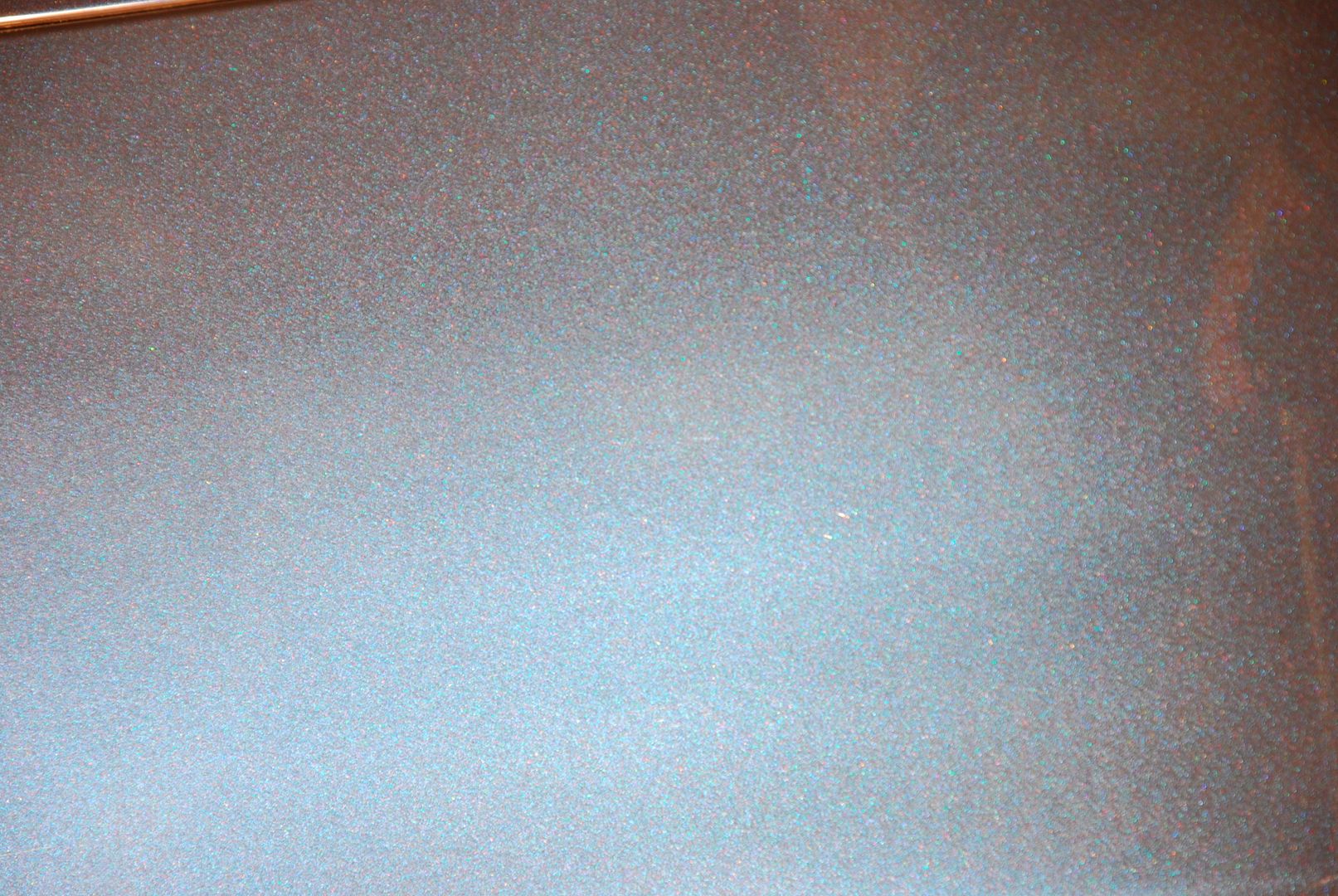

Here is a wonderful reason to rewash after polishing. This shows the beading from the polishing oils that are still on the car. At this point in the process we need sheeting, not beading.

A quick spray with some Optimum Power Clean helps break up the polishing oils and the beading.

After pre-treating all areas with Optimum power clean, I went ahead and started to re-wash the car. I had polishing dust everywhere that needed to be removed. For this wash I used a 50/50 mixture of Dawn and Chemical Guys Citrus Wash and Clear.

Again, it's really important to remove as much of the polishing oils during your wash as you can.

Every area of the car was given a thorough cleaning. Not one area was missed.

I reached out to a request for a Cquartz coating job. It was a brand new BMW 535 with 1000 miles on it. After a quick trip down to Princeton New Jersey for a visual inspection, I had a better idea of what I was in for. Luckily for me the owner was knowledgable enough not to wash the car in a swirl-o-matic, possibly inducing swirls and marring the paint, causing more work to be done. He left it dirty for me. I know it sounds weird but I appreciated that the car was left dirty before I got my hands on it. It really does make my life easier.

I began by cleaning the wheels using Sonax FE, Ez-Detail Brushes, and a DI Boars hair brush for the lug nuts. Why did I do the wheels first, so I wasn't sitting in water doing them after I washed the car. I knew it would get a second washing.

After finishing the wheels, I pre-treated the lower panels with IronX, then gave it a good wash using Ironx Soap Gel in my foam gun.

Since it was sunny out, I quickly brought the car inside to dry it. After dried I clayed the entire car. There wasn't much contamination for the bar to pick up, but it is a critical step when doing a coating. Thorough checking of the paint is always important to ensure you catch all of the imperfections.

Even though it is a new car it still had some issues that needed correction before coating the paint. I found one area in particular that had fairly excessive damage to the paint. I was able to correct this area using Meg's MF pads and D300. They corrected out really well.

There were some random scrapes on the paint throughout the car, nothing bad, but correction was needed.

I followed up with every inch of the paint getting polished with Menzerna 85RD to ensure I maximized the gloss in the factory clear.

The car also got the Tuff shine semi-permanent tire dressing applied. This is a two step process starting with their cleaning spray, and once the tires are dry apply their tire "clearcoat". This leaves the tires with a nice semi-permanent matte finish.

You can see the cleaner doing its job. I cleaned the tires three times until I no longer got any dirt from the tires.

Here is a wonderful reason to rewash after polishing. This shows the beading from the polishing oils that are still on the car. At this point in the process we need sheeting, not beading.

A quick spray with some Optimum Power Clean helps break up the polishing oils and the beading.

After pre-treating all areas with Optimum power clean, I went ahead and started to re-wash the car. I had polishing dust everywhere that needed to be removed. For this wash I used a 50/50 mixture of Dawn and Chemical Guys Citrus Wash and Clear.

Again, it's really important to remove as much of the polishing oils during your wash as you can.

Every area of the car was given a thorough cleaning. Not one area was missed.