Barry Theal

New member

This local dealership now does. :waxing:

Its only been a few months since we opened 3D Products of Manheim. Let me tell you it has been a huge success so far. Scott, Matt and Myself have been making a huge impact here locally distrubuting 3D Professional Car Detailing Products in Pennsylvania. As things move foward, our goal was to infiltrate into local dealerships and focus on a select group. In the few months since our opening we have made a statement and then some! Its been a huge blessing. Along the way we have established over 40 accounts already and pretty soon we will be launching our retail website. Along with selling products comes educating the end user on proper detailing and product usage. Several weeks back one of our lager accounts who have I think 9 new and used car dealerships ask us to come in and do some training. We set the date and had a blast. I was pretty excited about this and thought I would share some photos. I hope you enjoy them.

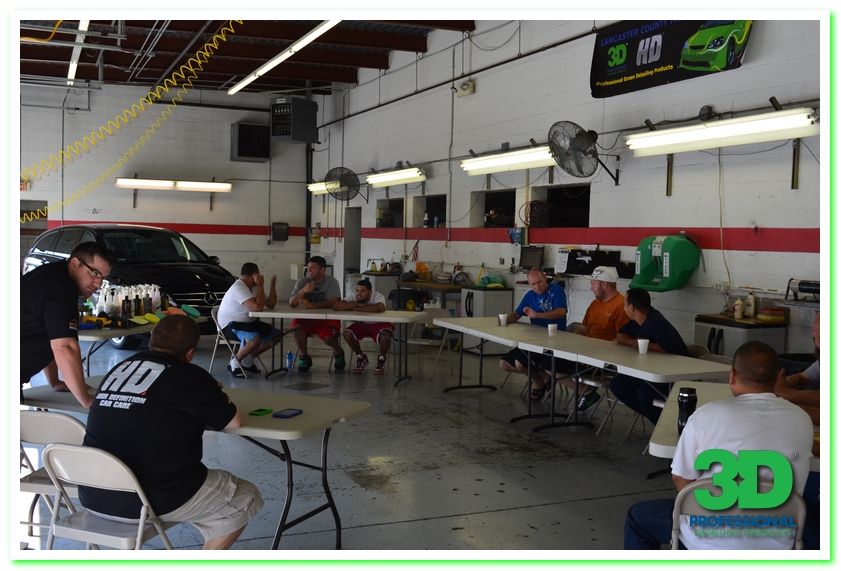

It was a small 6 hour training with the first half of it being educational and the second half being hands on. It was my focus to introduce proper DA paint correction and polishing.

First thing first! Lets get rid of the old suppliers banner and hang a brand spanking new one up!

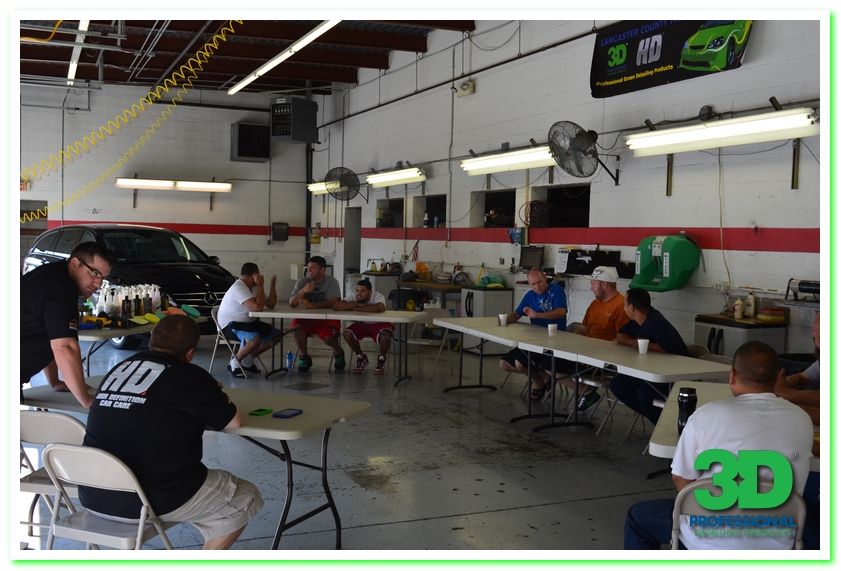

Here we were getting prepared for the event. I was about ready to start the Education Side of it. I had a white board set up. I was explaining the proper movents of DA Polishing. I got into all kinds of crazy things about stroke size, pressure, speed, and all the other crazy things thats involved with polishing.

Had the guys a little confused. Whats that shiny thing on that dewalt polisher? Yup thats the crazy defect killer called the Dynabrade strapped and loaded with a 3D Orange Foam Euro Pad.

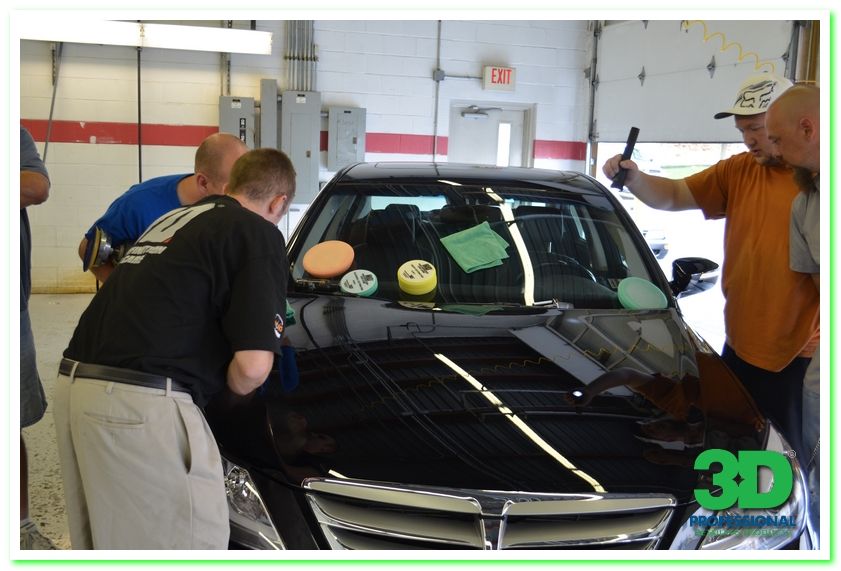

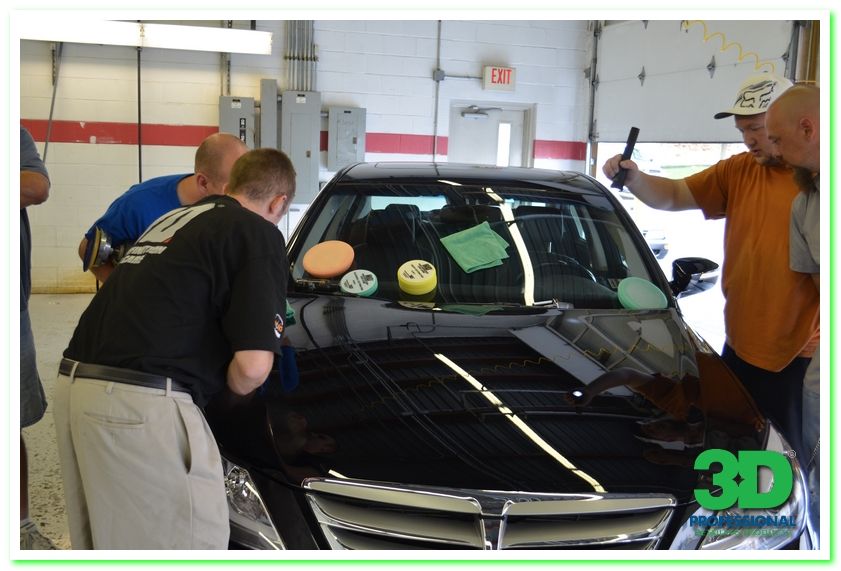

Here we began to use the 3D Nano Prep towel and 3D Final Touch to cleanse the paint surface and remove the surface contaminants. I was Point out some defects in the paint. It had some etching.

We were under flourecent lighting with isn't the greatest for spotting defects, so I broke out the Streamline LED light to really enhace the defects.

Here I was demonstrating proper machine speeds and settings. The 3D polisher was armed with our Ultrafiber Cuttiing Pads and some HD Uno.

Employees of the dealership really got involved and were loving the dynabrade.

This gentelman here is one of the painters at the bodyshop they have on premise who was intrigued by DA Polishing. We had a great conversation about sanding and polishing.

Here is Nick our parttime employee helping out. You may remember Nick as a helper in some of my write ups for Presidential Details.

Here is the Reconditioning Manager and myself talking a little. Its not just about polishing. We discussed shop effeincy and ways to improve there overall performance. This guys is all business and very smart in running a shop.

This gentleman never held a polisher till this moment. Withing minutes he had a dialed in finish like a boss!

Scotts knowledge of chemicals has really come along way.His efforts into building 3D Manheim has been incredible. Here he was discussing a bunch of samples we had.

At the end of the day all the employees recieved some free HD shirts courtesy of 3D Manheim, but now most importantly we had our first 3D Detailers Trained. It was a huge success. Its amazing what open minds can do!

At the end of the day I want to thank Nick, Scott and the incredible guys at the dealership for giving me one amazing day! :smile1:

Its only been a few months since we opened 3D Products of Manheim. Let me tell you it has been a huge success so far. Scott, Matt and Myself have been making a huge impact here locally distrubuting 3D Professional Car Detailing Products in Pennsylvania. As things move foward, our goal was to infiltrate into local dealerships and focus on a select group. In the few months since our opening we have made a statement and then some! Its been a huge blessing. Along the way we have established over 40 accounts already and pretty soon we will be launching our retail website. Along with selling products comes educating the end user on proper detailing and product usage. Several weeks back one of our lager accounts who have I think 9 new and used car dealerships ask us to come in and do some training. We set the date and had a blast. I was pretty excited about this and thought I would share some photos. I hope you enjoy them.

It was a small 6 hour training with the first half of it being educational and the second half being hands on. It was my focus to introduce proper DA paint correction and polishing.

First thing first! Lets get rid of the old suppliers banner and hang a brand spanking new one up!

Here we were getting prepared for the event. I was about ready to start the Education Side of it. I had a white board set up. I was explaining the proper movents of DA Polishing. I got into all kinds of crazy things about stroke size, pressure, speed, and all the other crazy things thats involved with polishing.

Had the guys a little confused. Whats that shiny thing on that dewalt polisher? Yup thats the crazy defect killer called the Dynabrade strapped and loaded with a 3D Orange Foam Euro Pad.

Here we began to use the 3D Nano Prep towel and 3D Final Touch to cleanse the paint surface and remove the surface contaminants. I was Point out some defects in the paint. It had some etching.

We were under flourecent lighting with isn't the greatest for spotting defects, so I broke out the Streamline LED light to really enhace the defects.

Here I was demonstrating proper machine speeds and settings. The 3D polisher was armed with our Ultrafiber Cuttiing Pads and some HD Uno.

Employees of the dealership really got involved and were loving the dynabrade.

This gentelman here is one of the painters at the bodyshop they have on premise who was intrigued by DA Polishing. We had a great conversation about sanding and polishing.

Here is Nick our parttime employee helping out. You may remember Nick as a helper in some of my write ups for Presidential Details.

Here is the Reconditioning Manager and myself talking a little. Its not just about polishing. We discussed shop effeincy and ways to improve there overall performance. This guys is all business and very smart in running a shop.

This gentleman never held a polisher till this moment. Withing minutes he had a dialed in finish like a boss!

Scotts knowledge of chemicals has really come along way.His efforts into building 3D Manheim has been incredible. Here he was discussing a bunch of samples we had.

At the end of the day all the employees recieved some free HD shirts courtesy of 3D Manheim, but now most importantly we had our first 3D Detailers Trained. It was a huge success. Its amazing what open minds can do!

At the end of the day I want to thank Nick, Scott and the incredible guys at the dealership for giving me one amazing day! :smile1: