Todd@RUPES

Just a regular guy

The Jaguar E-Type is considered a work of art, literally. It is the only car chosen by New York?s Museum of Modern Art to be on permanent display. This 1974 Series 3 model features a 5.3 liter Jaguar V12 producing 290 horsepower and gobs of low end torque. This particular E-Type belongs to one of our favorite clients and a man who demands concours level work on his daily drivers! (Not to mention great taste in cars as his Titanium Ferrari 360, Grigio Silverstone Ferrari F430, Tour De France Blue Ferrari 456, and Nero Maserati Quattroporte have all received our full treatment and have been the subjects of write ups on this site)

The plan of attack with this beautiful example of art was simple; bring it to Pebble Beach standard by taking each area of the cat to its highest potential.

Upon initial inspect, I was shocked to see how deep and reflective the paint was, and further shocked to see the amount of damage in the clear coat?s surface. Since we know that perfectly polished and jeweled paint will always reflect more light, we knew the car could look better? but we didn?t believe it. This car has an extremely high quality paint job, and we knew it would be a pleasure and an honor to see it right.

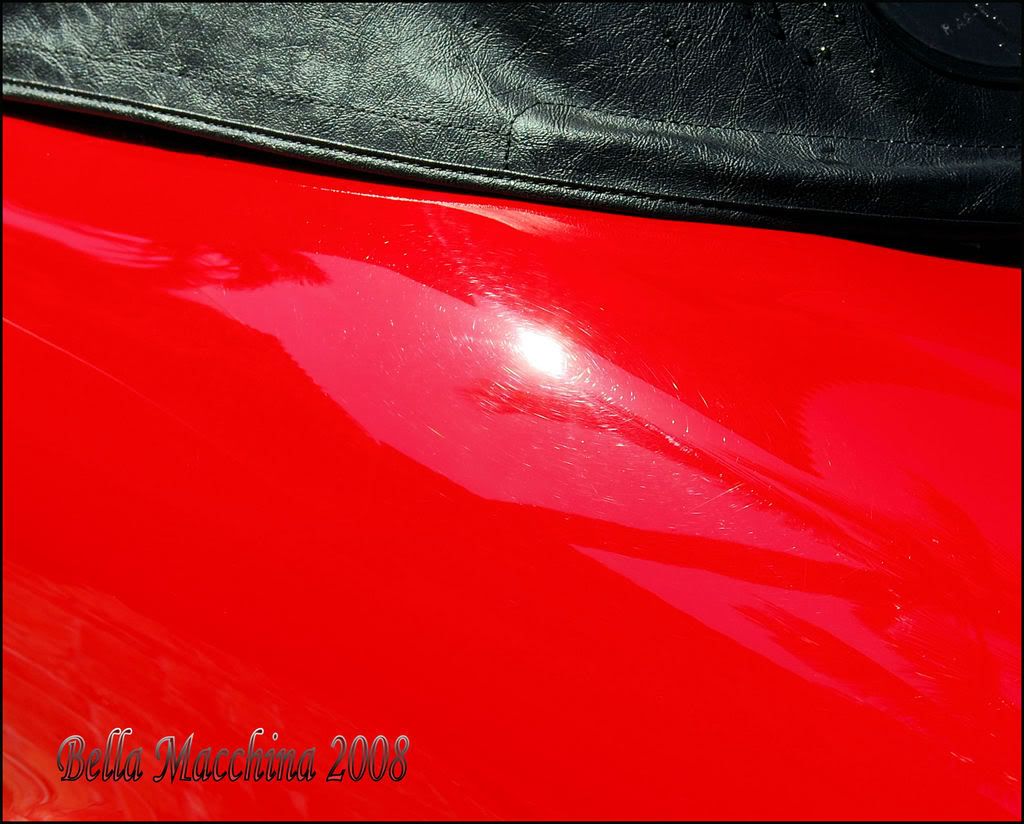

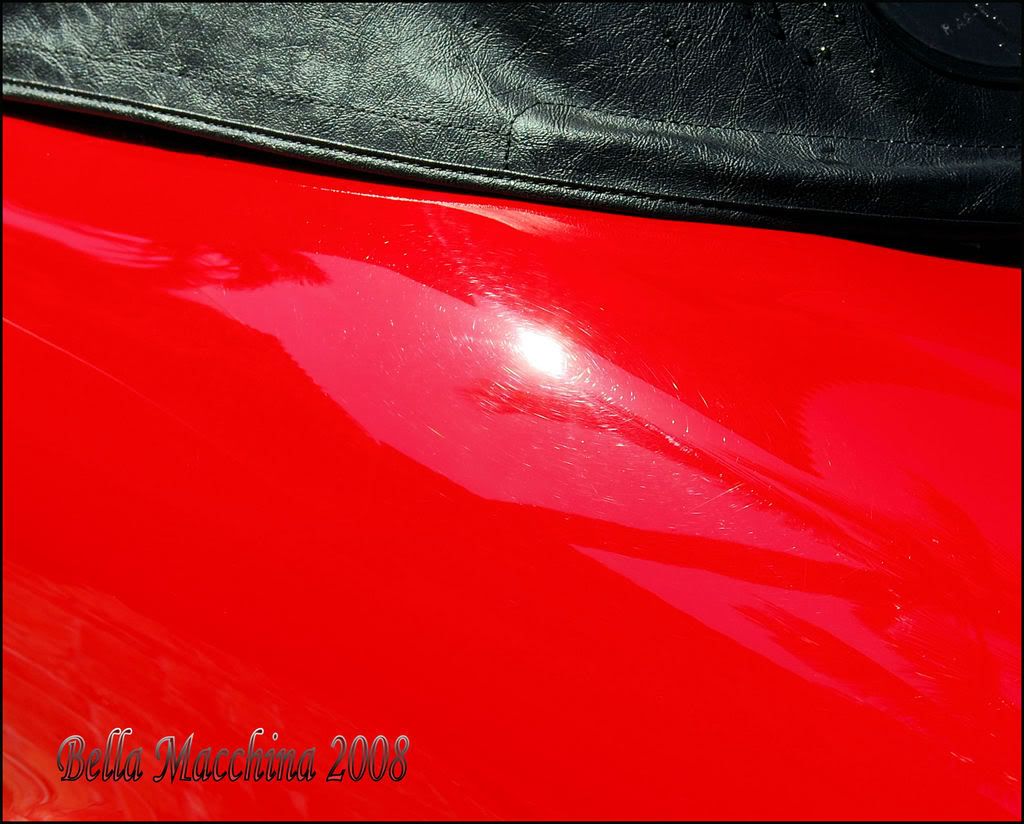

Initial inspect did reveal a significant amount of flaws in the paint?s surface, holograms, swirl marks, and R.I.D.S. Taking paint depth readings proved rather frustrating and useless and it was obvious by the variations in readings that the body had been mudded with a filler (such as bondo) and block sanded straight. Paint depth readings ranged from 11.5 mils to over 35 mils in some area?s, again indicative of mudding process. However the finish definitely had high quality clear coat and a lot of it (judging by the depth of the bare paint).

General Procedure and Process Outline

Exterior Paint Work

Wash entire car with P21s Total Body wash using two bucket method

Clay paintwork, glass, and trim using Sonus Gray clay using Zaino Z7 cut as lubricant

Rinse

Dry car using Ultimate Microfibers Waffle Weave?s and 2 220 MPH leaf blowers

Inspect paint and measure paint thickness

Polish Correction

- Meguiars M95 on a Meguiars So1o Yellow Wool pad at 2000 RPM x 2-4

- Menzerna PO85 3.02 on a Lake Country Green German Foam CCS Pad at

1700 RPM burnished down to 1200 RPM

- Menzerna PO85u on a Meguiars So1o Foam Finishing Pad @ 1500 rpm

jeweled down to 1000 RPM

4 inch spot pads where used in numerous areas to achieve 100 percent correction using the following steps

- Meguiars M95 on a Lake Country 4inch Purple Foam Wool Pad at 2000

RPM x 2-4

- 1Z Intensive Paste on a Lake Country 4inch Orange CCS pad at 1200 RPM

- Menzerna PO85u on a Lake Country 4inch Gray CCS pad at 1500 RPM

burnished down to 1000 RPM

Also certain areas required hand polishing (headlight buckets for example).

- Meguiars M105 by hand using Lake Country Yellow Foam (custom cut into

hand applicator)

- 1Z Intensive Paste by hand using Lake Country White Foam (custom cut)

- Meguiars ScratchX by hand using Lake Country Gray Foam (custom cut)

All chrome and trim on the exterior was hand polished using DeepFinish Deep Chrome and protected with Meguiars #16

The original top was washed with Meguiars APC 10:1 and topped with two coats of 303 Aerospace Protectant

After polishing the paint was rewashed then treated with Meguiars #7 to enrich the depth and wetness of the paint.

P21s 100% was used as the LSP for two coats

Tires/Wheels/Wheel Arch Process

The tires where scrubbed using Eminn Fabrik Tire Cleaner

The wheels where cleaned with Griot?s Garage Wheel Cleaner using the EZ Detail Brush and Swissvax Wheel Brush

The wheels where polished using Eagle One?s Never Dull and topped with Zaino Z-AIO

The tires where dressed with 2 coats of Zaino Z16 Tire Dressing

The wheel wheels where scrubbed with Meguiars APC 10:1 and dressed with Meguiars Hyperdressing 4:1

Interior Process

The interior was blown up using compressed air and various boars? hair brushes to remove loose dirt.

The carpet was removed, and stains where spot treated with Folex before the being shampooed using Meguiars ACP 10:1

The leather was treated with Leatherique Rejuvenator Oil, which was left to dwell for 6 hours before being wiped clean with Leatherique Pristine Clean

The interior vinyl and hard surfaces where cleaned using 1Z Cockpit Premium

All interior surfaces where treated with 303 Aerospace Protectant

The glass was cleaned with Meguiars ProLine Window Cleaner and sealed with Zaino Z-AIO

All interior metal was hand polished with Flitz

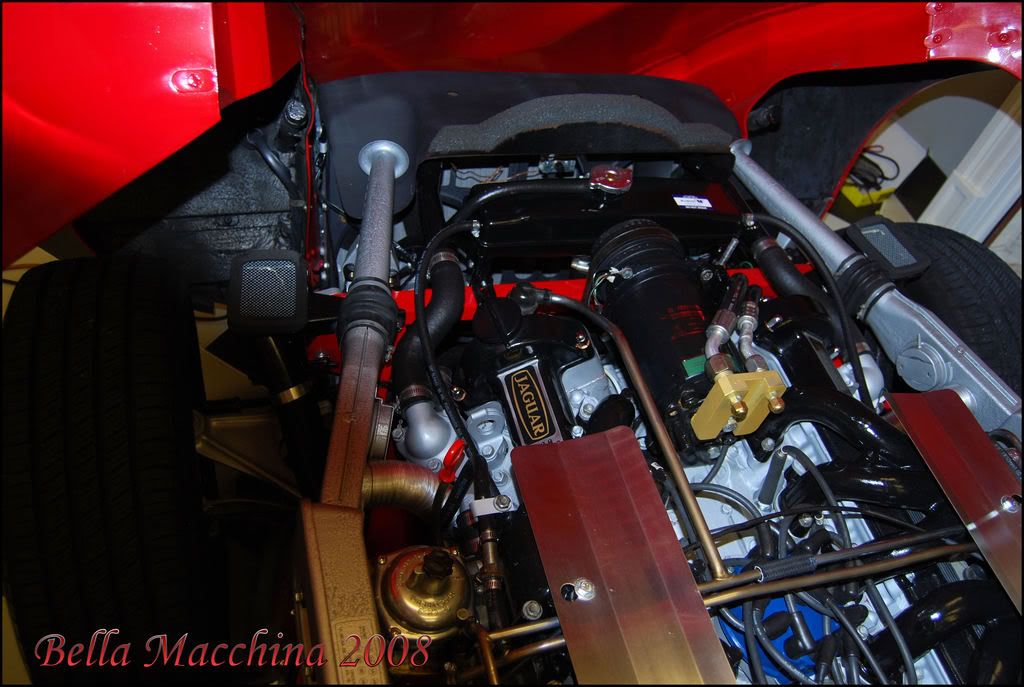

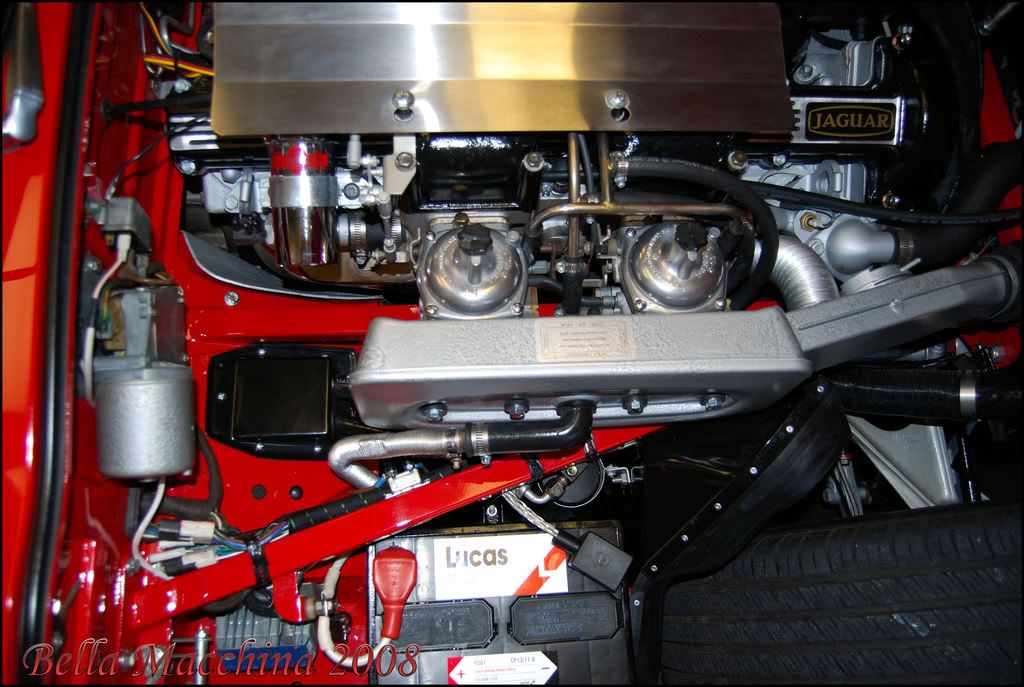

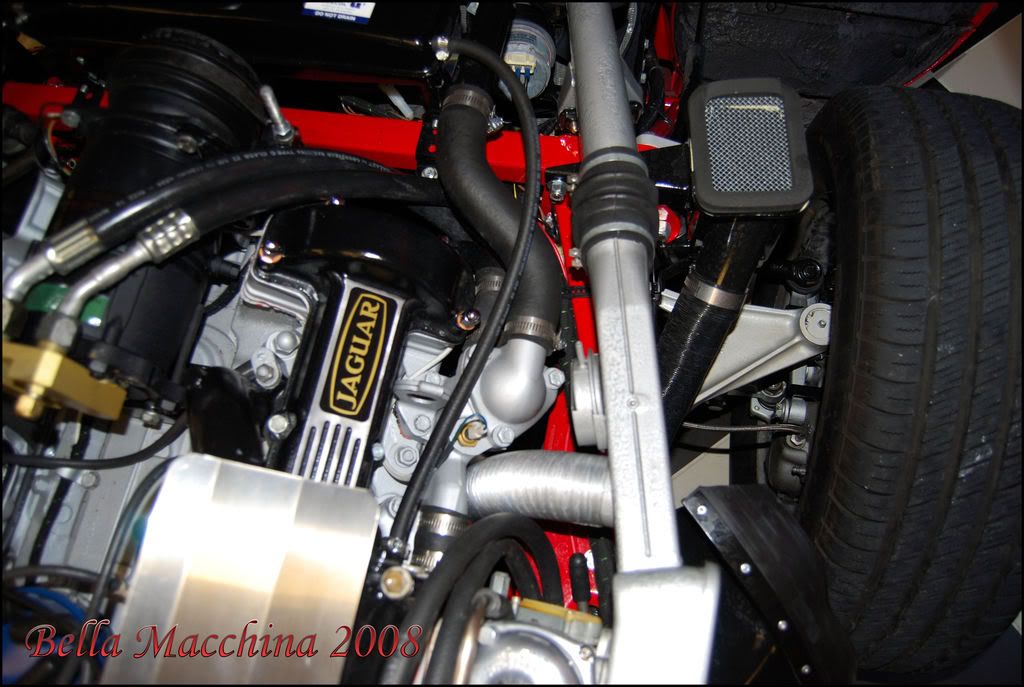

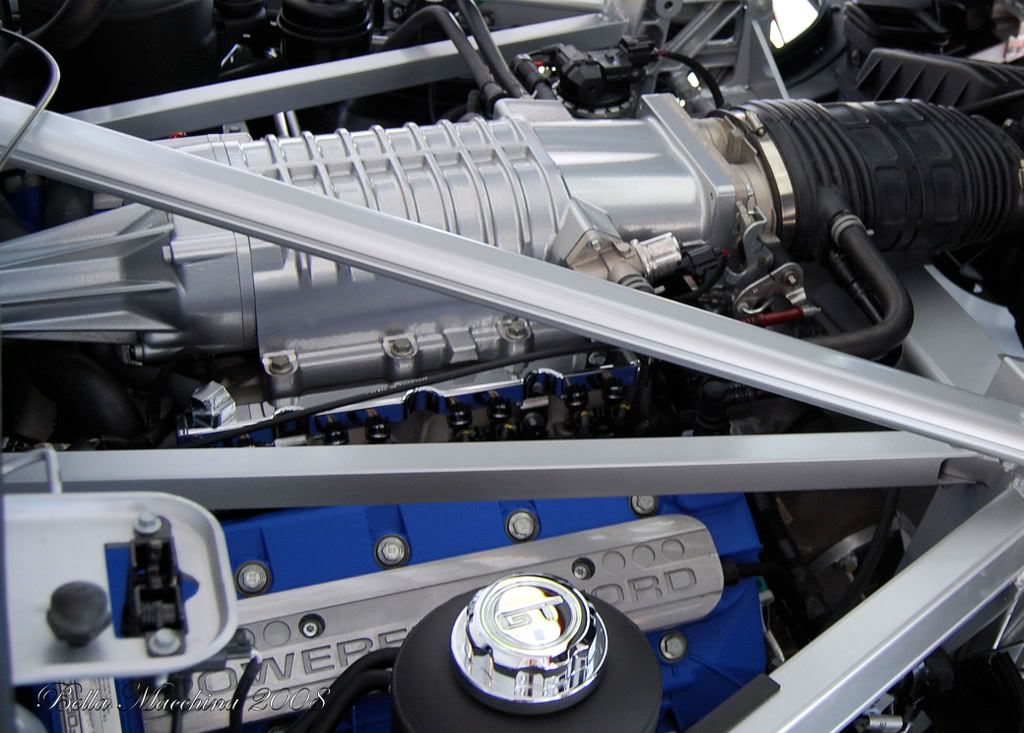

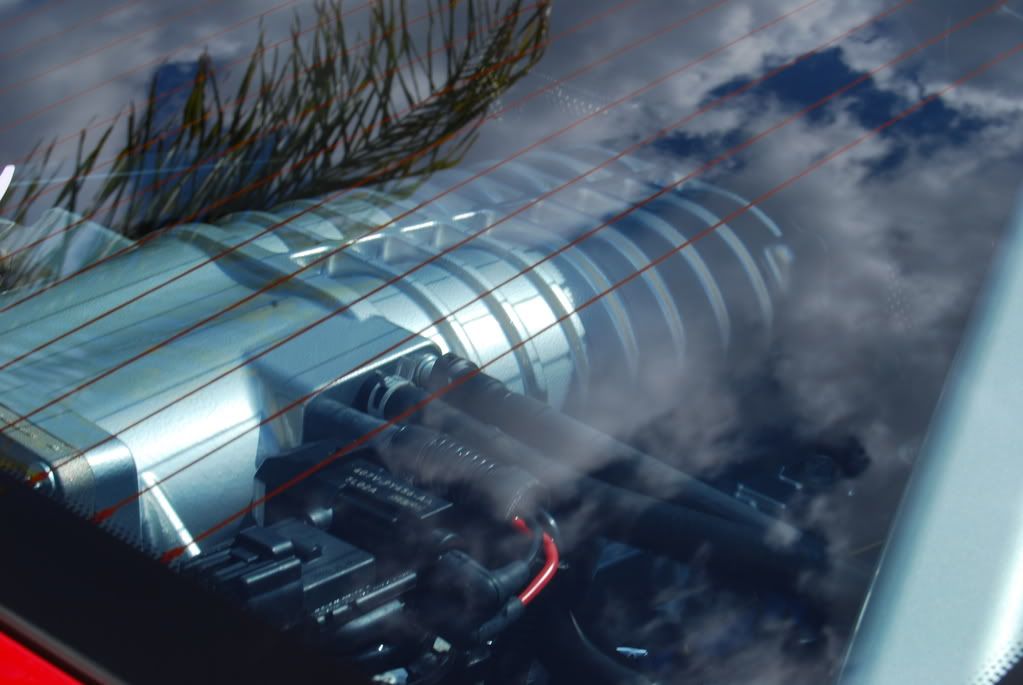

Engine Compartment and Trunk Process

The engine was wiped down using Meguiars APC 20:1 and damp cloth

All metal was polished using Mother Mag and Aluminum Polish using Lake Country Green Foam

All paint work under hood was polished with Meguiars #7 and topped with Meguiars #16

Meguiars Hyperdressing 4:1 and 2:1 was used on all black work under the engine compartment

Misc Processes

All jambs received Meguiars #7 topped with Meguiars #16

All weather stripping was cleaned using Meguiars #39 and topped with 1Z?s Gummi Phledge

Total Working Time: 23 Man Hours, non-stop

Okay let?s start with the pictures.

Some before pictures of the interior. The original carpets had 34 years worth of stains and grime and the leather was in need of cleaning.

Initial inspection of the paint revealed significant marring.

50/50's working toward perfection. Given the initial gloss and color of the paint I was pleasantly surprised to see how much improvement could be made.

I had Brian apply Leatherique to the interior leather surfaces and massaging a liberal amount of Rejuvinator Oil into the hides by hand.

A couple more 50/50's

The plan of attack with this beautiful example of art was simple; bring it to Pebble Beach standard by taking each area of the cat to its highest potential.

Upon initial inspect, I was shocked to see how deep and reflective the paint was, and further shocked to see the amount of damage in the clear coat?s surface. Since we know that perfectly polished and jeweled paint will always reflect more light, we knew the car could look better? but we didn?t believe it. This car has an extremely high quality paint job, and we knew it would be a pleasure and an honor to see it right.

Initial inspect did reveal a significant amount of flaws in the paint?s surface, holograms, swirl marks, and R.I.D.S. Taking paint depth readings proved rather frustrating and useless and it was obvious by the variations in readings that the body had been mudded with a filler (such as bondo) and block sanded straight. Paint depth readings ranged from 11.5 mils to over 35 mils in some area?s, again indicative of mudding process. However the finish definitely had high quality clear coat and a lot of it (judging by the depth of the bare paint).

General Procedure and Process Outline

Exterior Paint Work

Wash entire car with P21s Total Body wash using two bucket method

Clay paintwork, glass, and trim using Sonus Gray clay using Zaino Z7 cut as lubricant

Rinse

Dry car using Ultimate Microfibers Waffle Weave?s and 2 220 MPH leaf blowers

Inspect paint and measure paint thickness

Polish Correction

- Meguiars M95 on a Meguiars So1o Yellow Wool pad at 2000 RPM x 2-4

- Menzerna PO85 3.02 on a Lake Country Green German Foam CCS Pad at

1700 RPM burnished down to 1200 RPM

- Menzerna PO85u on a Meguiars So1o Foam Finishing Pad @ 1500 rpm

jeweled down to 1000 RPM

4 inch spot pads where used in numerous areas to achieve 100 percent correction using the following steps

- Meguiars M95 on a Lake Country 4inch Purple Foam Wool Pad at 2000

RPM x 2-4

- 1Z Intensive Paste on a Lake Country 4inch Orange CCS pad at 1200 RPM

- Menzerna PO85u on a Lake Country 4inch Gray CCS pad at 1500 RPM

burnished down to 1000 RPM

Also certain areas required hand polishing (headlight buckets for example).

- Meguiars M105 by hand using Lake Country Yellow Foam (custom cut into

hand applicator)

- 1Z Intensive Paste by hand using Lake Country White Foam (custom cut)

- Meguiars ScratchX by hand using Lake Country Gray Foam (custom cut)

All chrome and trim on the exterior was hand polished using DeepFinish Deep Chrome and protected with Meguiars #16

The original top was washed with Meguiars APC 10:1 and topped with two coats of 303 Aerospace Protectant

After polishing the paint was rewashed then treated with Meguiars #7 to enrich the depth and wetness of the paint.

P21s 100% was used as the LSP for two coats

Tires/Wheels/Wheel Arch Process

The tires where scrubbed using Eminn Fabrik Tire Cleaner

The wheels where cleaned with Griot?s Garage Wheel Cleaner using the EZ Detail Brush and Swissvax Wheel Brush

The wheels where polished using Eagle One?s Never Dull and topped with Zaino Z-AIO

The tires where dressed with 2 coats of Zaino Z16 Tire Dressing

The wheel wheels where scrubbed with Meguiars APC 10:1 and dressed with Meguiars Hyperdressing 4:1

Interior Process

The interior was blown up using compressed air and various boars? hair brushes to remove loose dirt.

The carpet was removed, and stains where spot treated with Folex before the being shampooed using Meguiars ACP 10:1

The leather was treated with Leatherique Rejuvenator Oil, which was left to dwell for 6 hours before being wiped clean with Leatherique Pristine Clean

The interior vinyl and hard surfaces where cleaned using 1Z Cockpit Premium

All interior surfaces where treated with 303 Aerospace Protectant

The glass was cleaned with Meguiars ProLine Window Cleaner and sealed with Zaino Z-AIO

All interior metal was hand polished with Flitz

Engine Compartment and Trunk Process

The engine was wiped down using Meguiars APC 20:1 and damp cloth

All metal was polished using Mother Mag and Aluminum Polish using Lake Country Green Foam

All paint work under hood was polished with Meguiars #7 and topped with Meguiars #16

Meguiars Hyperdressing 4:1 and 2:1 was used on all black work under the engine compartment

Misc Processes

All jambs received Meguiars #7 topped with Meguiars #16

All weather stripping was cleaned using Meguiars #39 and topped with 1Z?s Gummi Phledge

Total Working Time: 23 Man Hours, non-stop

Okay let?s start with the pictures.

Some before pictures of the interior. The original carpets had 34 years worth of stains and grime and the leather was in need of cleaning.

Initial inspection of the paint revealed significant marring.

50/50's working toward perfection. Given the initial gloss and color of the paint I was pleasantly surprised to see how much improvement could be made.

I had Brian apply Leatherique to the interior leather surfaces and massaging a liberal amount of Rejuvinator Oil into the hides by hand.

A couple more 50/50's