Introduction

You may have heard, either on a disscusion forum, from other enthusiasts, or on the back of a polish bottle, the terms diminishing or non diminishing abrasives. At the end of the day, when you use a polish to remove paint defects, the focus is on the end result. The manufacturer of your polish of choice will choose the correct type of abrasive to get the results you want. If you keep the focus on the end results and trust the manufacturer (Autopia-CarCare.com only carries the finest brands and products) then the ingredients may not matter to you. However, if you are of an inquisitive mind and like details on how things work, then this article is for you.

What Is An Abrasive?

An abrasive (grain) is the material inside a paint correction liquid, known as a polish, that allows it to work. Polishes are a bunch (as in millions) of abrasive grains held in suspension to create a liquid/paste for application. The abrasive is what allows the polish to remove material and create a smoother, more reflective surface. The suspension (other ingredients in the polish) is often a blend of solvents and lubricants allow the abrasives to flow over the surface in order to create a level surface with out scratching.

Polishes (abrasive liquids) are used in many industries to either clean the surface (toothpaste is an abrasive that uses aluminum hydroxide or silica to clean the surface of the teeth with out removing enamel), remove aged or dead material (facial exfoliation) or to create a more level, more reflective surface (a jeweler using a rouge to polish a precious gem).

Many types of abrasives are used in paint polishes, although the most common are aluminum oxides (there are different grades of aluminum oxide), silica, and diatomaceous earth. In the old days, painters and detailers would often use products like cornstarch as an abrasive. As paint has become thinner and more delicate, the use of highly refined (micro-sized) abrasives has become more prevalent. In particular the use of aluminum oxide, because it available in many different grades and can be engineered to a degree, has become popular.

Diminishing Vs. Non Diminishing Abrasives

Diminishing abrasives, when exposed to friction, begin to break apart. This process of dissolving is known as `diminishing`. Aluminum oxide, as an abrasive, is extremely hard (Mohs of Hardness it is a 9/ a diamond is a 10). When aluminum oxide is fully broken down it is called a crystal or primary crystal. No amount of polishing, past this point, is going to refine the abrasive or dissolve further (any significant amount). The shape (cube, triangle, sphere, rhombus), size, and sharpness of the aluminum oxide crystal will have a significant impact on how the polish cuts and the quality of the finish it leaves behind.

Abstract Thought: Think of a diminishing aluminum oxide abrasive like a bushel of grapes. Each grape represents the crystal (fully broken down abrasive grain). When the abrasive is fresh (virgin) it is large. These large abrasives (bushels of grapes) remove defects quickly. However, as they dissolve the individual grapes (abrasive primary crystals) break off. The abrasive becomes finer and finer until all that remains is a just the grapes (fully dissolved abrasives/primary crystal abrasives)

Non Diminishing Abrasive polishes use only the crystal form of aluminum oxide. They are not engineered to dissolve or fracture into smaller pieces because they are already in their smallest, most refined form.

Abstract Thought: In the bushel of grape example above, non diminishing abrasives would represent only the grapes.

Note: Technically the crystal abrasive will still dissolve, although the rate is so slow when exposed to the forces of machine polishing, that it is insignificant in this discussion.

The Functional Difference

Since diminishing abrasive polishes start with a larger abrasive (more aggressive) that, over time, becomes finer and finer (and polishes its own scratches away) you may ask yourself how a non diminishing abrasive polish, which only uses fine abrasives can deliver the same amount of cut (polishing power)? The answer is in the amount of abrasives used.

In order for a non diminishing abrasive polish to deliver enough polishing power to remove paint defects it must use more abrasives in general.

Abstract Thought: Imagine you have to level a corn field that is of significant size. You could hire 10 people and arm them with machetes or sickles and have them swing quickly and wildly across the field until all of the stalks have been chopped down. Or your could arm 50 people with surgical blades and have them focus on one stalk at a time. The end result will be the same, the field will be level. If you have enough people with surgical blades it will take the same amount of time as well.

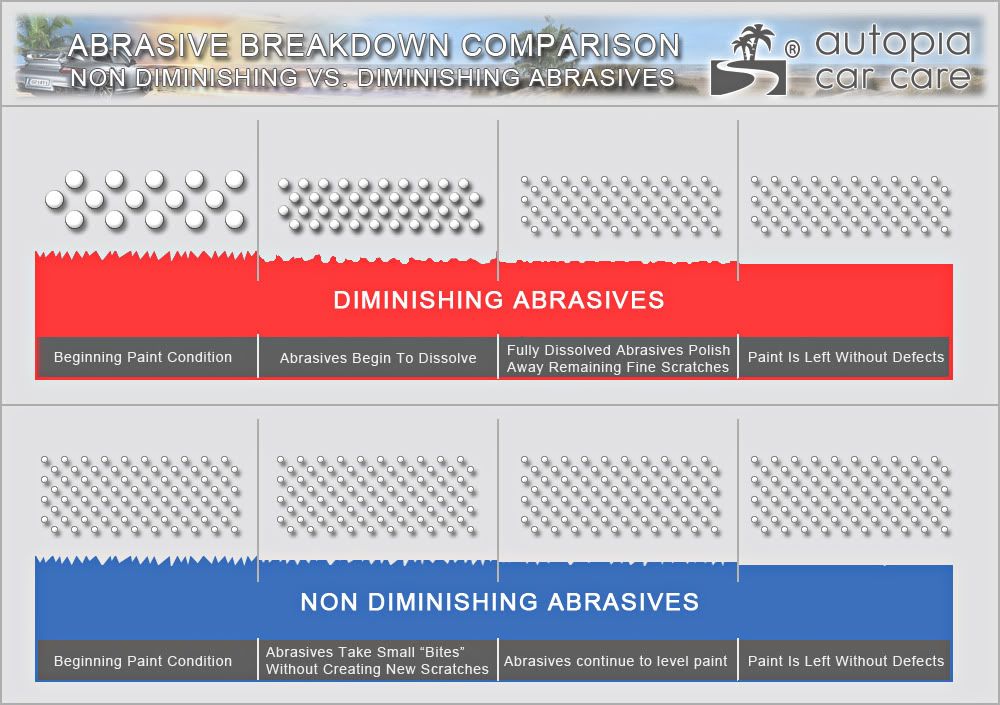

Looking at the chart above you will notice that end result is the same, perfectly level paint. When you look at the details you will begin to see some slight differences.

Looking at the red paint first, you will notice that the diminishing abrasive polishes leave the paint uneven at first, imparting their own scratches when the polish is fresh. As the abrasive becomes finer and finer, the polish goes to work removing the scratches it created in order leave the paint level. Also not, then when fully dissolved, their is less total abrasive content in the diminishing abrasive polish.

Looking at the blue paint, which is being polished with a non-diminishing abrasive polish, you can note that polish is not creating its own scratches, but rather taking little bites out of the existing scratches, until the surface is level. Also note that their is a higher level of abrasives active. This does effect the way the polishes will behave at the end of the polishing cycle.

The Functional Difference: When applying a diminishing abrasive polish, you must work the polish through out the cycle to fully dissolve the abrasives and achieve the highest quality finish possible. When working a non-diminishing abrasive polish you can stop as soon as the defects are removed or the desired finish quality is achieved.

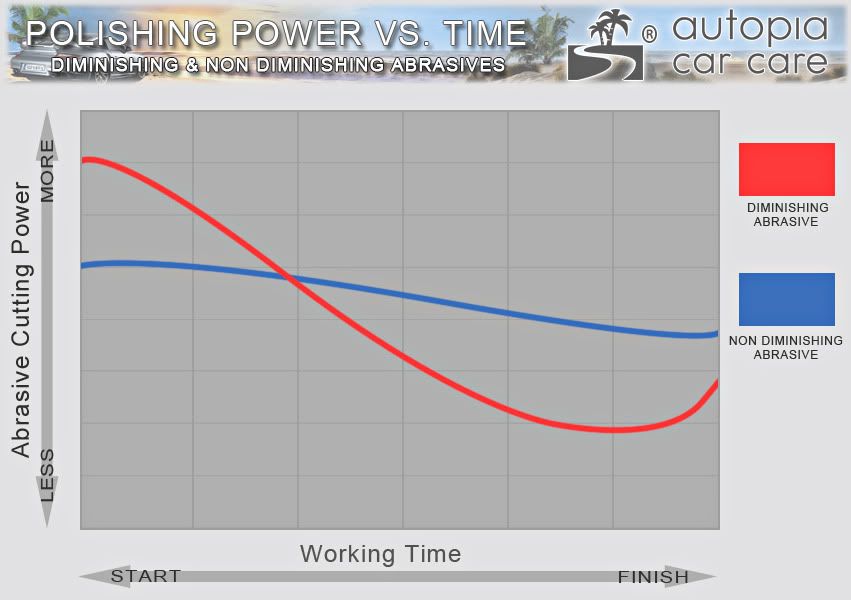

Rate Of Cut: Power Vs Time

While both types of polishes will achieve similar results, the way they achieve the result is much different. Diminishing abrasives (red) will start much more aggressive, then loose their cutting ability as the abrasives dissolve. When they are fully dissolved they will offer little cutting action.

Non diminishing abrasive polishes will tend to have less initial cut, but will maintain an even level of cut for a longer period. The polish will still loose some polishing power as abrasives become coated with removed paint, dust away, or the lubricants no longer function optimally.

Note: Towards the end of each buffing cycle each type of polish will begin to become more aggressive as the abraded paint residue causes the abrasives clump together. Because non diminishing abrasive polishes have a higher load of active abrasives (and thus remove more paint in a given time at the end) they are more effected.

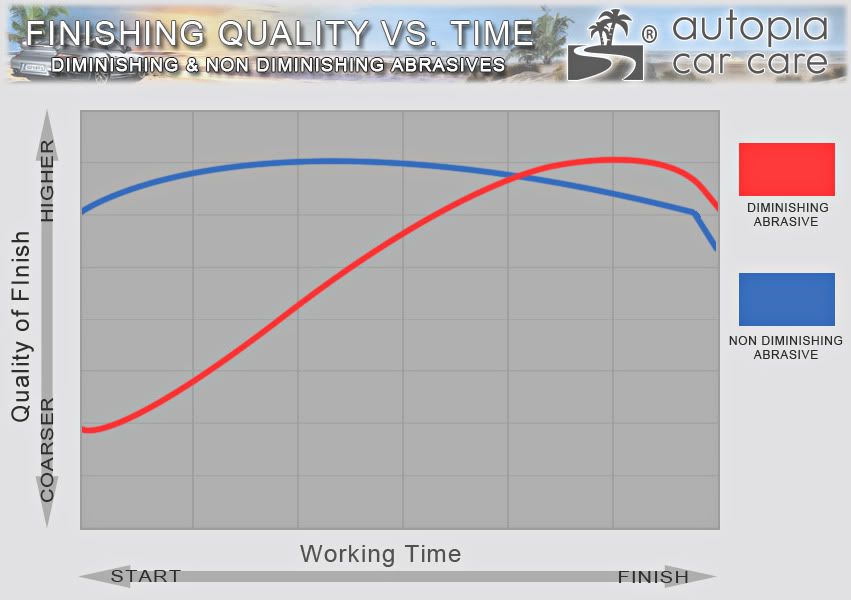

Quality Of Finish: Finish Vs Time

A diminishing polish, as shown in the graph above will achieve a higher quality (level) of finish later in its polishing cycle. There is a sweet spot, when the polish has become fully dissolved, and has been given enough time to polish away its own scratches, that result in the highest quality finish polish. Working too long (over working) will result in the quality of finish starting to degrade.

A non diminishing polish will achieve it`s highest quality almost immediately, since we are starting with a crystal abrasive. Since there is a higher load of abrasives working at a give time, non diminishing abrasive polishes are more sensitive to over working.

Functional Difference: The main functional difference when achieving the best finish is to stop polishing in the sweet spot, when the polish is fully diminished yet has been given time to remove scratches caused earlier in the process. When using a non diminishing abrasive polish it is important to spot polishing as soon as the desired quality has been achieved. Non diminishing polishes, when used for maximum surface quality, should not be overworked as their is no advantage to doing so.

Using Diminishing Abrasive Polishes

When using a diminishing abrasive polish it is important to work the polish through out its entire buffing cycle. This gives the abrasives time to break down, allowing the polish to leave a higher quality finish. When using a diminishing abrasive polish to remove paint defects (such as compounding or cutting the paint) you will receive some benefit to priming the pad with product as well as reducing pressure and speed through out the polishing cycle. When using a diminishing abrasive polish for final polishing make sure to work the polish through the cycle but do not over work the product. Always keep your pad clean for best results.

Using Non Diminishing Abrasive Polishes

Using a non diminishing abrasive polish is a little different then using a traditional (diminishing) abrasive polish. There is a higher load of ultra-refined crystal abrasives working at any given time. Because non diminishing abrasive polishes are more susceptible to over working it is important stop polishing as soon as the desired effect is achieved (either removing defects or finishing). Also, because of the reasons above, it is extremely important to keep the polishing pad clean and free of residue or excess polish.

Autopia-CarCare.com carries some of the finest paint polishes available today. Here is a look at some of our most popular diminishing and non diminishing polishes:

Diminishing Abrasive Polishes

BLACKFIRE SRC Compound

BLACKIFRE SRC Finishing Polish

Menzerna PG1000

Menzerna SI1500

Menzerna PF2500

Menzerna SF4500

Wolfgang Total Swirl Remover 3.0

Wolfgang Finishing Glaze 3.0

Non Diminishing Abrasive Polishes

Meguiars M105 Ultra Cut Compound

Meguiars M205 Ultra Finishing Polish

Meguiars M86 So1o Cut & Polish Cream

Meguiars D300 DA Microfiber Correction Compound

Optimum Hyper Compound Spray

Optimum Hyper Polish Spray

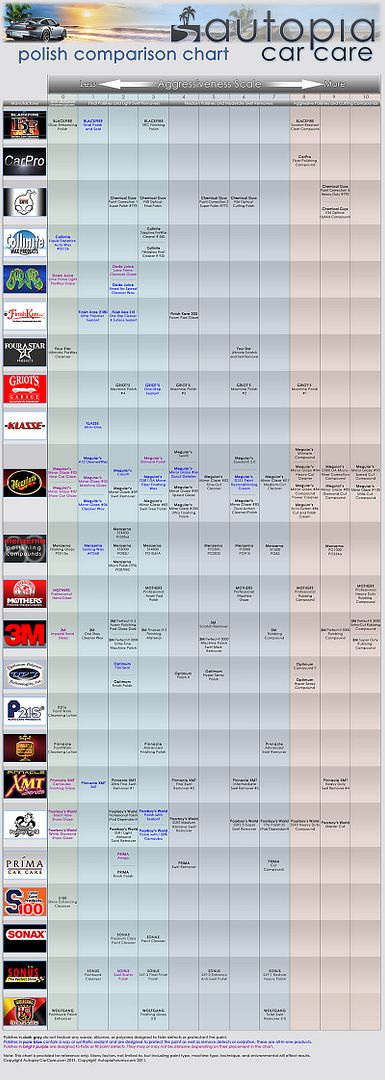

These are just some of the paint correction polishes that Autopia carries. You can see more of them on our paint correction chart below:

Click here for 1400 Pixel Wide Hi-Res Chart.

Click here for 1000 Pixel Wide Med-Res Chart

Click here for 800 Pixel Wide Med-Res Chart

Below is the 800 Pixel Wide Low-Res Chart. (click the tab above the picture to see the full 800 pixel wide size)

Results 1 to 15 of 15

Threaded View

-

08-28-2012, 01:06 PM #1

The Difference Between Diminishing and Non-Diminishing Abrasive Polishes

Post Thanks / Like - 1 Likes, 0 Thanks, 0 Dislikes WaxAddict liked this post

WaxAddict liked this post

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Difference between Diminishing and Standard Abrasive Polishes

By togwt in forum Autopia Detailing WikiReplies: 0Last Post: 11-27-2011, 07:13 AM -

Difference between Diminishing and Standard Abrasive Polishes

By togwt in forum Autopia Detailing WikiReplies: 0Last Post: 11-27-2011, 07:11 AM -

Difference between Diminishing and Standard Abrasive Polishes

By togwt in forum Autopia Detailing WikiReplies: 0Last Post: 11-20-2011, 08:29 AM -

Non-Diminishing Abrasives

By BIGDAVE in forum Car Detailing Product DiscussionReplies: 3Last Post: 04-09-2011, 02:46 AM

Reply With Quote

Reply With Quote

Bookmarks