I am proud to bring to you this product review of the NEW Backing Plate System for the FLEX 3401 VRG by Lake Country

This new backing plate system gives you the choice of swapping out backing plates for your Flex 3401 from the factory 5.5 to a 4" or 6"

Why is this called a System you ask?

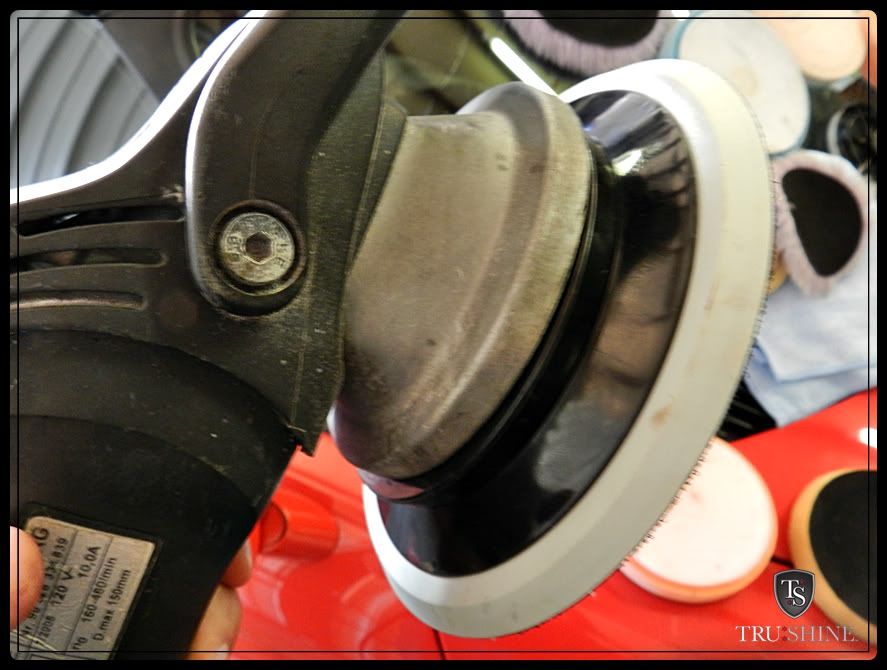

This new "System" includes 1 main geared backing plate that will attach to the gear housing of the FLEX.

And the other part of the backing plate attaches to it

here it is with the 6.5" backing plate (*Note* the 6.5" backing plate will not be manufactured, a 6" backing plate will be coming with the kit out instead)

Here are the backing plates on a few different types of pads.

(6.5" BP on the 6.5" PFW pad) Which I LOVED but used a lot of back muscle to work it but gave amazing cut

Here is the 6.5" PFW pad on the Factory 5.5" BP to show you the difference

Here is where it gets real good! a 4in Backing Plate on the FLEX 3401, I know a lot of you are going to be excited to try this out and it really make a big difference when using the 4in pads on the Flex. you can really control the machine a lot better and it uses A LOT less Back Muscle to work it.

Here is the 4in Tang pad on the New Backing plate

here it is with the 4" PFW pad

And here it is with the 5.5in Tangerine pad (For those who have a lot of 5.5" pads it works great and still leaves room around the edge of the pad instead of being right on the edge like the factory 5.5" BP

Here is the Factory 5.5" backing plate with the 5.5" Tang pad (Notice how the BP is all the way on the edge of the pad leaving no cushion for the pad and the chance of damaging the vehicle if you were to get to close to an corner or somthing)

4" PFW pad on the 4" BP

5.5 tang pad in use on the 4" BP

While I was at SEMA this year, I got to meet up and discuss some of my thoughts on this product and ask a few questions with one of Lake Country`s Finest, Eric Dunn

Some of the questions I had

1. Why design a backing plate that has two Pieces? This was one of my first questions, Why this design? and Eric replied back with a great answer.

Answer: Why not reduce some of the cost for Both the Consumer, and the Manufacturer? the piece with the gearing that attaches to the FLEX housing is a VERY expensive part to design and get manufactured. So imagine having to build on the second piece with the Velcro onto EVERY SINGLE Backing plate. What if you wanted a 6" and you have already bought the 4". Now you have to buy the second one? that can get pretty pricey for the customer to buy, and the manufacturer to make it.

My Thoughts:

This is why this design is great, you have one gear piece and you can order 4" backing plates or 6" backing plates and it cuts down the cost because you will already have the most expensive part (the Gear piece).

So all in all, I love this design. it will be cheaper in the long run, only having to buy a cheaper adapter instead of buying a whole backing plate that is only set with one size..... (And who knows, maybe other sizes will come out in the future, like the factory size 5.5" and you will already have the gear piece. that would be a lot cheaper then buying the Factory FLEX backing plate for $30)

Some of my other thoughts:

1. I love having the ability to swap out to a 4" BP, sometimes you just need to get into a smaller tighter area and still get the FLEX results.

2. I like using the PFW pad with a bigger backing plate as it gives me more control behind the cut.

3. in the future it will cost less for me to have different backing plates or replacement backing plates versus buying expensive FLEX brand of BP

I am still using these products testing their limits and keeping in touch with Eric at LC. I will be very excited to see these released, Lake country has put a lot into the design and quality of this product and I am doing my best to test it`s limits and see how I can help improve it in any way that I can.

I hope you enjoyed this review. there will be more product reviews coming in the future.

-Eric Witt of Tru Shine Detailing

Results 1 to 1 of 1

-

12-28-2011, 06:06 PM #1Doing it BIG!

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Lake Country 5.50" Thin Foamed Wool Pad Review

By mnehls86 in forum Detailing Product ReviewsReplies: 17Last Post: 09-15-2014, 04:22 PM -

Brand new flex 3401 with LC backing plate system

By success44 in forum The Swap MeetReplies: 14Last Post: 04-15-2013, 10:44 PM -

Product Review: Lake Country`s New "LC-3401 Backing Plate System"

By Eric_Witt in forum Detailing Product ReviewsReplies: 17Last Post: 12-30-2011, 02:13 PM -

New Lake Country Polishing System coming soon: The "1 Pad" Finishing System.

By debaser330ci in forum Machine Polishing & SandingReplies: 30Last Post: 10-12-2010, 10:24 PM -

Backing plate mfgs? Meguiar`s vs Lake Country

By crew219 in forum Machine Polishing & SandingReplies: 7Last Post: 03-21-2007, 11:53 PM

Reply With Quote

Reply With Quote

Bookmarks