I should have purchased the makita off the ebay store a few months back. it was so cheap.

Results 16 to 25 of 25

Thread: Small polishers vs big polishers

-

03-02-2016, 02:48 PM #16

Re: Small polishers vs big polishers

Post Thanks / Like - 1 Likes, 0 Thanks, 0 Dislikes Stokdgs liked this post

Stokdgs liked this post

-

03-02-2016, 05:28 PM #17

Re: Small polishers vs big polishers

If the PE8 hits a sale im all over it. The GG6 is ok with a 3" but time for some surgical equipment.

-

03-03-2016, 06:54 AM #18

Re: Small polishers vs big polishers

Something to consider if you are going to use a small diameter pad on a rotary...

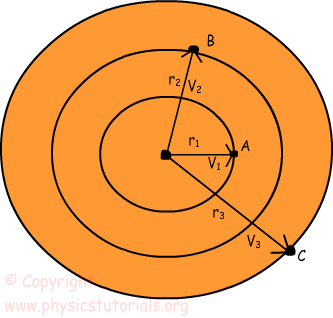

A rotary gets the majority of its polishing power from edge speed. The smaller you make the pad, the less edge speed you have... A 3-inch pad will travel 1/2 the speed of a 6-inch pad at the same RPM. A 2-inch pad will travel 1/3 the speed at the same RPM and a 1-inch pad will travel 1/6 the speed at the same RPM.

When designing the Nano - a polisher built from the ground up for spot correction - this was a primary consideration. The end result is a tool that will run at 5000 RPM at max speed. This sounds like a lot, but keep in mind that the pad diameter in rotary mode is 1.2 inches (approx.).

So a 1.2-inch pad at 5000 RPM is the same edge speed as a 6-inch pad at 1000 RPM. The smaller the pad, the higher the RPM needs to be on a rotary to maintain polishing power.

On a random orbital polisher, the opposite is true. Most of the pad speed comes from the orbital action. The beauty of an orbital polisher is that orbital speed is the same at any point on the pad.

Just some things to consider Post Thanks / Like - 8 Likes, 1 Thanks, 0 Dislikes

Post Thanks / Like - 8 Likes, 1 Thanks, 0 Dislikes Oldfordisbetter thanked for this post

Oldfordisbetter thanked for this post

-

03-03-2016, 10:15 AM #19

Re: Small polishers vs big polishers

Good info. Thanks a lot Todd

-

03-03-2016, 10:18 AM #20

-

03-03-2016, 11:53 AM #21

Re: Small polishers vs big polishers

Great points! I`m having flashbacks to physics class. This is called Tangential Speed (where velocity changes depending on the distance from the center of a rotation).

Anyone can use a few online calculators to find the Tangential Velocity with their pad size and speed setting. I just ran a few calculations and even with a small pad, you can get some very high tangential velocity numbers; which is why detailers should still be very careful with these small polishers (and would explain how I ended up burning through an edge with a PE8 and a 2 inch pad).Formula:

Vt = r ω

Where, Vt - Tangential Velocity (m/s)

r - Radius

ω - Angular Velocity (rad/s)

p.s. luckily the burn through was in the engine bay of my personal car.Instagram: www.instagram.com/rayswaydetailing

Facebook: www.facebook.com/RaysWayDetailing

Website: www.RaysWayDetailing.com

Post Thanks / Like - 2 Likes, 1 Thanks, 0 Dislikes Stokdgs thanked for this post

Stokdgs thanked for this post

-

03-03-2016, 12:50 PM #22

Re: Small polishers vs big polishers

I tried getting the PE8 when it was on an open box deal. Somebody beat me to it. I, too, think it`s time for some surgical stuff. Just yesterday I ordered the adapter to run rotary BPs on a DA, along with Flex 1" BP and pads.

You`re hardcore, Vega! Thanks for also giving ME flashbacks from those physics classes. Ahhh good times

-

03-03-2016, 02:57 PM #23

Re: Small polishers vs big polishers

Great point Todd.

One should also consider that the pressure on the surface increases quadratically as the pad size shrinks. The pressure of the machine weight may be negligible with a 7" pad spinning at 1000rpm, but when that pressure is 49x greater with a 1" pad, it may begin to have a greater contribution to correction than the edge speed.

Get those rupes engineers to dust off their differential equations text books, do some observations, and find the break point for pad size vs edge speed controlling the amount of cut. If time allows, please provide this for every conceivable pad, polish, paint and machine combination. I`ll be interested to see their published results 100 years from now.Post Thanks / Like - 4 Likes, 1 Thanks, 0 Dislikes Todd@RUPES thanked for this post

Todd@RUPES thanked for this post

-

03-04-2016, 04:11 PM #24

Re: Small polishers vs big polishers

Awesomeness! I think it will take more than 100 years to publish those results, considering that every few months new pad designs and polish manufacturers emerge.

One thing that I tell people is to run the nano with almost zero pressure. The entire weight of the tool, while not much when spread over the surface area of an 7-inch pad, is quite significant when applied to a 1-inch pad. Great observation

-

03-04-2016, 04:12 PM #25

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

The 3D POLISHERS ARE IN!

By Thomas Dekany in forum 3D / High Definition Car CareReplies: 17Last Post: 06-21-2012, 11:25 AM -

Looking for polishers

By Thomas Dekany in forum Professional Detailer General DiscussionReplies: 4Last Post: 08-07-2009, 04:28 PM -

Wen polishers

By shotime in forum Auto Detailing 101Replies: 8Last Post: 08-17-2007, 09:23 AM -

Polishers?

By Richard M. Lyon in forum Detailing Product ReviewsReplies: 8Last Post: 06-28-2006, 09:39 AM -

Anyone use these polishers?

By AZ Ferrari Man in forum Auto Detailing 101Replies: 3Last Post: 10-25-2004, 07:58 PM

Reply With Quote

Reply With Quote

Bookmarks