I use the term rotary for any machine that has forced rotation only. The typical buffer is a rotary machine.

For the machines that have an orbit but let the pad float free I use the term random orbital.

For machines that have both forced rotation, the pad is driven by planetary gears as with the Makita BO6040, the Bosch dual action sander, etc. I use the term dual action.

That`s how I use the language and I`m not trying to be the speech police here, but I think there needs to be a clear distinction between the three different actions. Calling a random orbital (free floating pad) a dual action (forced rotation) as if it is the same thing isn`t accurate and creates a lot of confusion.

Robert

Results 1 to 15 of 43

-

07-15-2012, 01:43 PM #1

-

07-15-2012, 02:20 PM #2

That`s a good start to standardize machine terminology...

What gets overlooked too often is that one must be a student before becoming a teacher.

-

07-15-2012, 02:24 PM #3

What i don`t like is when any RO or DA is just referred to as a pc. A pc is a porter cable, as in the name brand. But I agree completely with the OP, calling the polisher by the right term would help save many from confusion.

-

07-15-2012, 03:51 PM #4

Porter Cable machines were the first ones that obtained volume used due to the concerns with the first Infiniti Q45`s and their flourinated clears, in the late 80`s. Mequiars was the leader on finding the use for the Porter Cable and broadened it`s visability to the industry.

As a result, the term "pc" become part of the detailer lanquage, much as Kleenex, being the first highly advertised and marketed facial tissue, is the "term" still used by many when they request a facial tissue.

Other mass market products have attained similar status, however, no matter how much time/money and such are spent, it sometimes just doesn`t happen.

Grumpy

-

07-15-2012, 04:09 PM #5

Originally Posted by Ron Ketcham

Originally Posted by Ron Ketcham

:werd: Old habits die hard.Charlie

Automotive Appearance Specialist - Serving Greater Lansing, Michigan

http://www.cchautoappearance.com/

-

07-15-2012, 04:54 PM #6

I don`t use my PC (Griot) as much as my Flex.

Originally Posted by Ron Ketcham

Originally Posted by Ron Ketcham

-

07-15-2012, 07:06 PM #7

Until the early to mid 70`s, a "rotary buffer" was actually a grinder, most were one speed, 5,000 RPM, fixed and that is what we had to buff out color sanding, etc with, no foam pads, just twisted wool 4 ply yarn cutting pads and genuine lambs wool pelt pads for polishing.

Had a selection of maybe 5 or 6 compounds and 5 or 6 polishes, paste wax was the main final used.

That what the world was when I was first learning to run a buffer.

Grumpy

-

07-15-2012, 07:43 PM #8

Originally Posted by Ron Ketcham

Originally Posted by Ron Ketcham

wow, I think I understand why you are called grumpy lol

-

07-15-2012, 08:32 PM #9

An old painter taught me how to make a better "polish" for the final buff on a lacquer finish.

We took some DuPont #7, added some corn starch, some mineral or whatever oil was handy, a bit of water and went at it.

The DuPont #7 was ok for some things, as was some of the old Mequiar`s back then, but on a fresh lacquer, a couple of days old, the "mix" worked better.

Grumpy

-

07-16-2012, 03:15 AM #10

Originally Posted by WhyteWizard

Originally Posted by WhyteWizard

I LOVE THIS TOPIC! Thanks Bob for bringing it up. Good to see you posting. I like an old pro`s point of view.

That being said... I`ve listed my comment of disagreement and explanation below.

Originally Posted by RZJZA80

Originally Posted by RZJZA80

Yeah, I really don`t like it either.

Originally Posted by Ron Ketcham

Originally Posted by Ron Ketcham

True. I recall reading about your introduction to the machine awhile back.

If I recall correctly, you were with a couple Meguiar`s guys at the docks in Long Beach working on getting some cars squared away upon their arrival into the USA. Correct me if I`m wrong.

Back to WhyteWizard`s point of the thread:

I disagree that the designation is not accurate. I count the random rotation as an action DEFINITELY, making the random orbital a true dual-action machine (orbital and random rotation created by centripetal force). Just because it`s not belt, gear, or directly driven doesn`t discount the motion. In fact, I think that if the random orbital did not exist in its current form (and nobody thought of building it using the common design), someone would be trying to figure out or would have figured out how to offer up random rotation, using some sort of mechanical slip-action device. It`s simply too capable and desirable a feature.

In my eyes, claiming it`s not a dual-action machine is akin to discounting the drive capability of a transmission that uses a torque converter (or fluid coupler) , versus one that uses a clutch and pressure plate.

I don`t doubt that the original intent or use of the term dual-action was likely used in conjunction with a machine that featured a gear or direct drive of some sort. But, as time goes by, specific terms become slang, or used as a loose definition rather than a specific name of a machine. Just try and ask for the air-powered palm-style random orbital in a body shop! Everyone`s in too big a hurry (or it`s too loud to hear all those words), so the term DA identifies the machine just mentioned. If you want the BIG GUN, you ask for a "mud hog" (heavy duty, large stroke, Bondo® eating random orbital or forced rotation orbital).

I like to use the terms:

• Rotary

• Orbital

• Random Orbital

• Forced Rotation Orbital

• Dual Mode

Looking through recent manufacturers literature, it seems most are avoiding using the designation dual-action altogether, except interestingly, Meguiar`s! Their G110v2 random orbital machine is actually named Professional Dual-Action Polisher. As Ron Ketcham mentioned, Meguiar`s introduced it to the masses for use as a paint polishing tool. Even though I personally may have used the term DA in my writings perhaps 3 or 4 times over the past few years, I make every effort to use the proper term random orbital.

Here`s some of the latest literature and images I could find online, and with exception of Meguiar`s, the term dual action is not being used:

Meguiar`s G110v2 is named the Professional Dual Action Polisher:

Flex uses the term Orbital Polisher to describe its XC 3401 VRG:

Rupes uses the term Planetary Sander to describe its EK 150AE:

Makita calls it`s BO6040 (a favorite of the WhyteWizard) a Random Orbit Sander with switchable Forced Rotation:

Bosch says the 1250 DEVS features switchable Turbo driven eccentric orbit mode:

More to follow.

-

07-16-2012, 03:25 AM #11

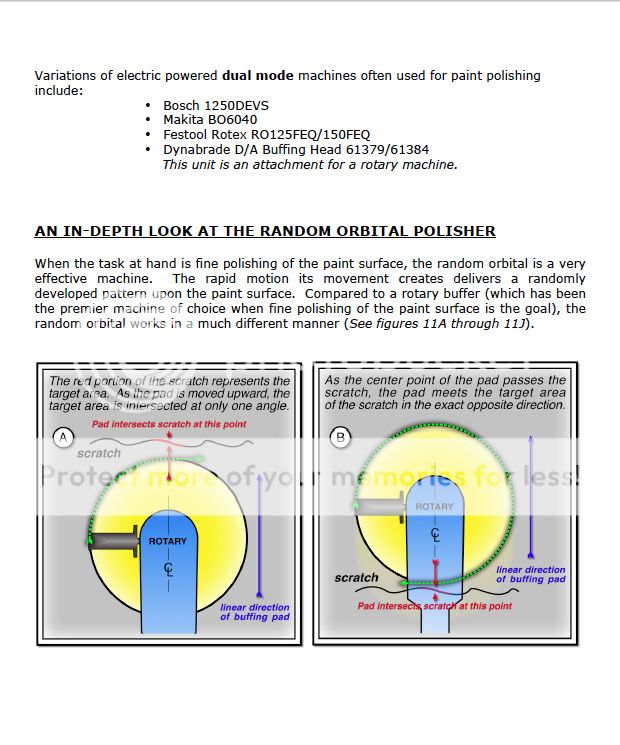

Sometime around 2009, I was in the midst of writing a paper about using M105 and M86 with a random orbital. Back then, the idea that a random orbital could equal or rival the rotary buffer for defect removal and final polishing was new (and a bit controversial).

The opening pages of the paper discussed the different types of polishing machines and the terminology used to describe the actions they created. Had WhyteWizard never broached this topic, I might not have drug the opening pages out of the mothball pit. Thanks, Bob.

Thanks for reading! :heelclick

-

07-18-2012, 11:48 AM #12

Kevin,

From your post back to me: "Back to WhyteWizard`s point of the thread:

I disagree that the designation is not accurate. I count the random rotation as an action DEFINITELY, making the random orbital a true dual-action machine (orbital and random rotation created by centripetal force). Just because it`s not belt, gear, or directly driven doesn`t discount the motion. In fact, I think that if the random orbital did not exist in its current form (and nobody thought of building it using the common design), someone would be trying to figure out or would have figured out how to offer up random rotation, using some sort of mechanical slip-action device. It`s simply too capable and desirable a feature.

In my eyes, claiming it`s not a dual-action machine is akin to discounting the drive capability of a transmission that uses a torque converter (or fluid coupler) , versus one that uses a clutch and pressure plate.

I don`t doubt that the original intent or use of the term dual-action was likely used in conjunction with a machine that featured a gear or direct drive of some sort. But, as time goes by, specific terms become slang, or used as a loose definition rather than a specific name of a machine. Just try and ask for the air-powered palm-style random orbital in a body shop! Everyone`s in too big a hurry (or it`s too loud to hear all those words), so the term DA identifies the machine just mentioned. If you want the BIG GUN, you ask for a "mud hog" (heavy duty, large stroke, Bondo® eating random orbital or forced rotation orbital)."

The reason I call any machine with a free floating backing plate random orbital is that the orbit is consistent but the rotation/spin isn`t. That`s something you pointed out as an advantage in your post. Whether its the old wax master or the most current machine, if it`s got a free floating backing plate there`s no transmission, or torque converter or belt or clutch to mechanically drive the pad so the rotation is random. There are no cars with random speed drive trains - variable yes - but only random if they`re on their way to be repaired.

Like I said, I`m not trying to be the language police here, but there are problems associated with terms being thrown around without consistent meanings. When we get this settled maybe we can move on to: wax, glaze, filler, sealer, correction creme, etc. I say this by way of invitation, why don`t you do it, I`m not all that interested, lol.

I`m am thinking seriously about doing a test of the various machines to show which ones get the most work done in the least time. I`m working out the protocol. I want to standardize the amount of pressure, the size and material used for the pad, the surface and the material used between the pad and the surface. I`m thinking just plain water misted onto the surface as consistently as possible is what I`ll use but I`ve got the rest pretty much worked out. Now I just have to get some test panels painted and get it set up.

I expect to run the machines the same amount of time with the same pressure the same pad the same pad angle, against test panels that all start out at the same temperature then measure the temperature as the machines are pulled away. I`d be interested in your thoughts.

Robert

-

07-18-2012, 11:59 AM #13

Absolutely FANTASTIC, Kevin!

The post and the documented information really delves into the various machines, their actions, how they accomplish the work, etc.

Very, very wonderful and professional information.

Grumpy

-

07-18-2012, 01:01 PM #14

I`ve always enjoyed and learned from informative machine polisher posts by either you or Zoran (think that`s how he spelled his forum name) for the amount of detail they go into >>>

What gets overlooked too often is that one must be a student before becoming a teacher.

-

07-18-2012, 06:52 PM #15

Originally Posted by Ron Ketcham

Originally Posted by Ron Ketcham

Thank you so much, Ron. I`m glad to hear this.

Originally Posted by TOGWT

Originally Posted by TOGWT

Thanks, Jon. Interestingly, I used to chat with Zoran all the time. Then for some reason unknown to me... he decided not to interact with me, or perhaps we had a disagreement? Regardless, I enjoyed his posts, and he gave me some very nice pads (which I used while testing out HD Uno Advanced Cut (which I appreciated).

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Time Line for HD Polishers?

By CAdetailer in forum 3D / High Definition Car CareReplies: 2Last Post: 09-10-2012, 11:50 AM -

Detailing Terms???

By Beemerboy in forum Hot TubReplies: 13Last Post: 02-24-2010, 11:12 PM -

Good Way to Establish Busines in a new area?

By Labster in forum Professional Detailer General DiscussionReplies: 7Last Post: 11-13-2007, 06:09 AM -

Establish and Promote a `Detailing Day` in your area.

By mirrorfinishman in forum Auto Detailing 101Replies: 2Last Post: 05-20-2004, 09:15 AM -

What some terms mean?

By Beemerboy in forum Hot TubReplies: 2Last Post: 05-06-2003, 05:23 PM

Reply With Quote

Reply With Quote

Bookmarks