The new Meguiars microfibre DA correction system is getting more and more air time now as the system is being used by more people and the same messages seem to be coming out - speed of correction and the movement of the level of correction capable in given times by DA. So we thought it was about time to challenge the Meguiars system in a head to head with how we would have corrected by DA before it existed! To see what the differences really are

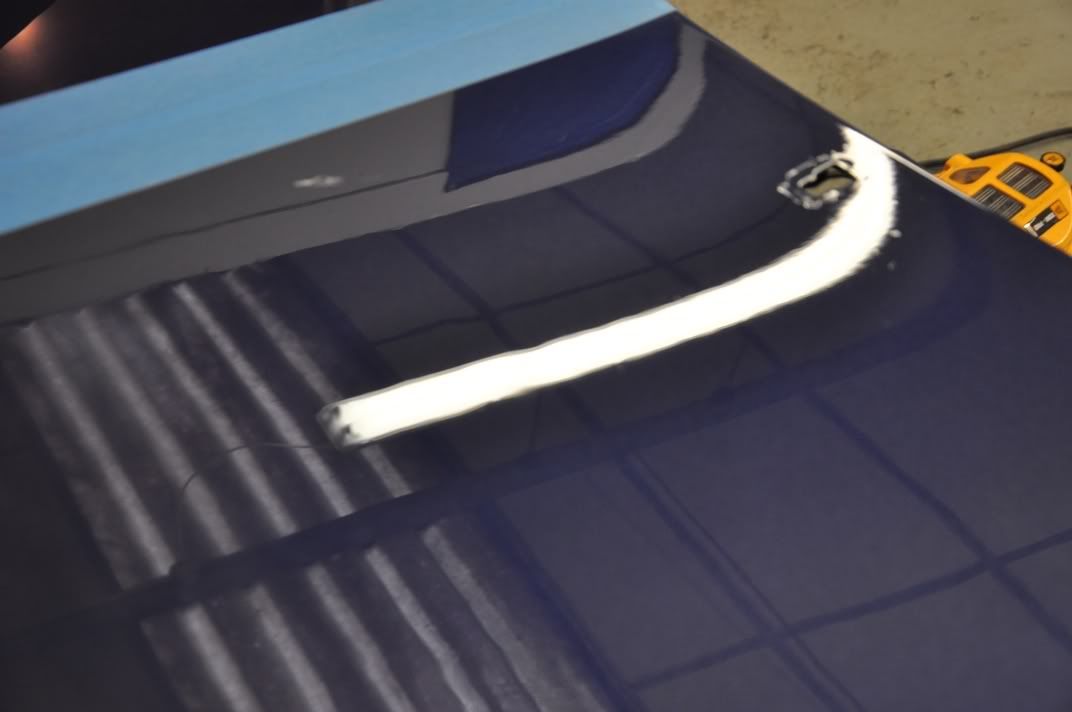

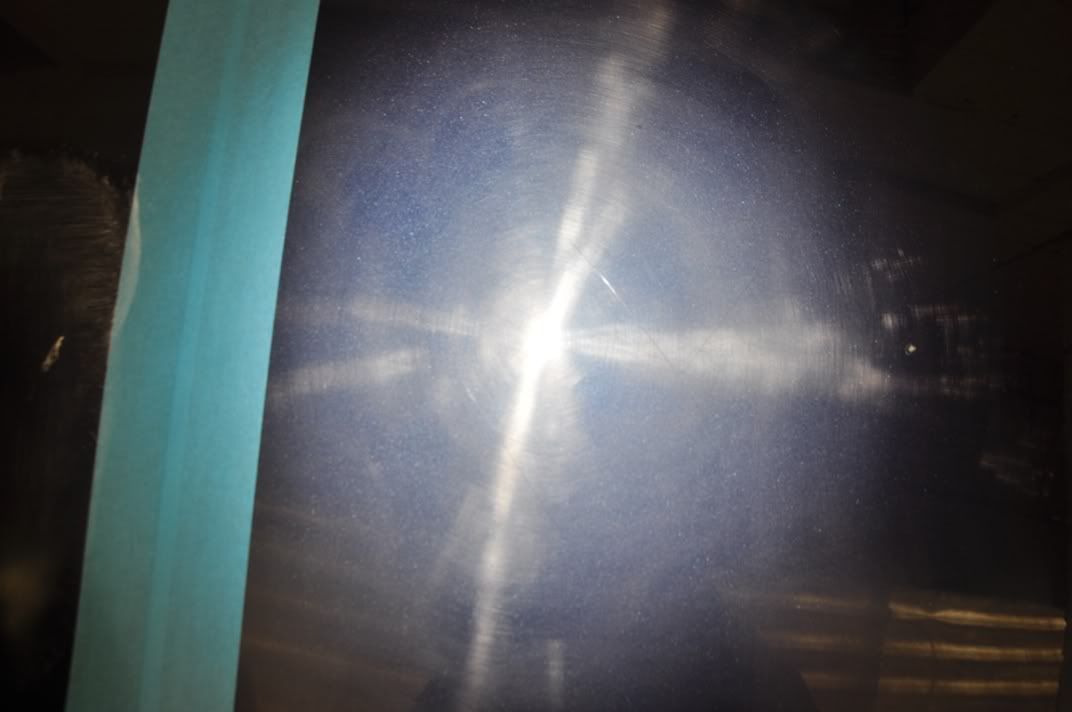

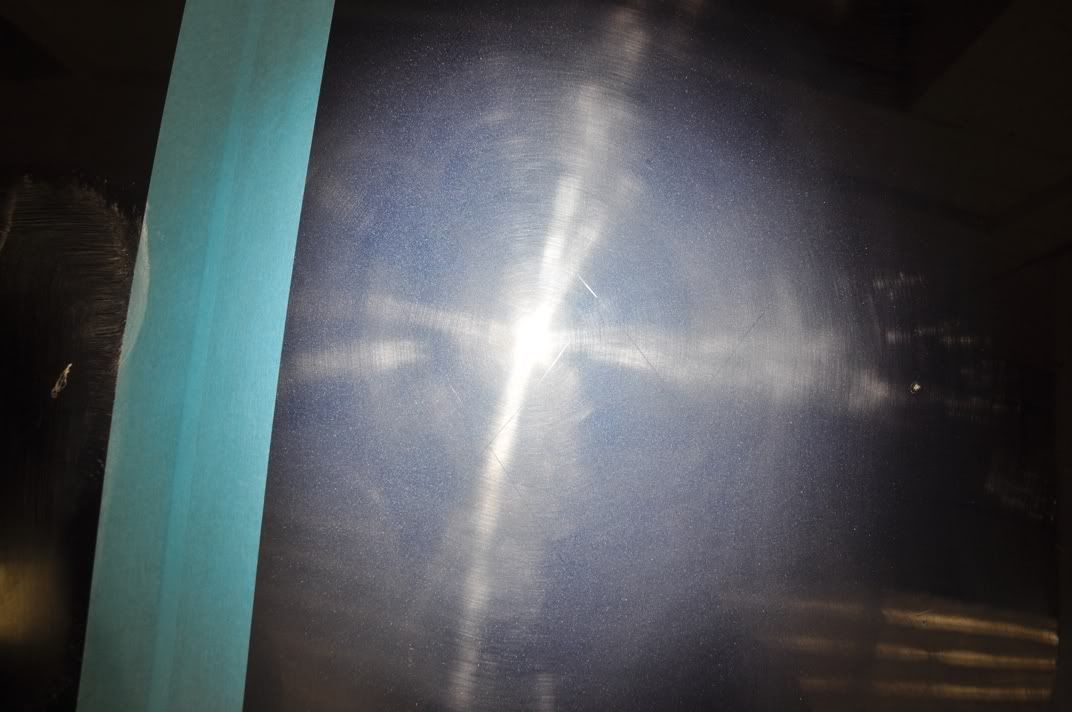

So - take one Mercedes blue bonnet, and marr it with a brush and some grit, and a key to set the challenge:

I think this sets the heavy correction challenge quite well - 2000 grit sanding marks, grit brush and deep RDS inflicted by a key, so a wide variety of severe marring to sort out.

Menzerna S100 Power Gloss on DRC1000 Yellow Cutting Pad

Traditionally, working by DA, heavy correction would be achieved using a cutting foam pad such as the DRC1000 Yellow, and an aggressive compound. Chosen here is Menzerna S100 Power Gloss, in our experience, Menzerna compounds seem to have the edge on a DA, the abrasives seem to suit the oscillating motion of the machine more than those of Fast Cut for example. The video below shows a typical correction set with Menzerna on foam, Gordon using speed 2 to spread and working up to speed 5 - 5.5 on the DAS-6 Pro and using moderate pressure to achieve the correction:

âªDSC 0012â¬â - YouTube

Note: fast passes at slow speed to spread and then slow hand movements with the machine while breaking the compound down and an overall work time of circa 5 minutes.

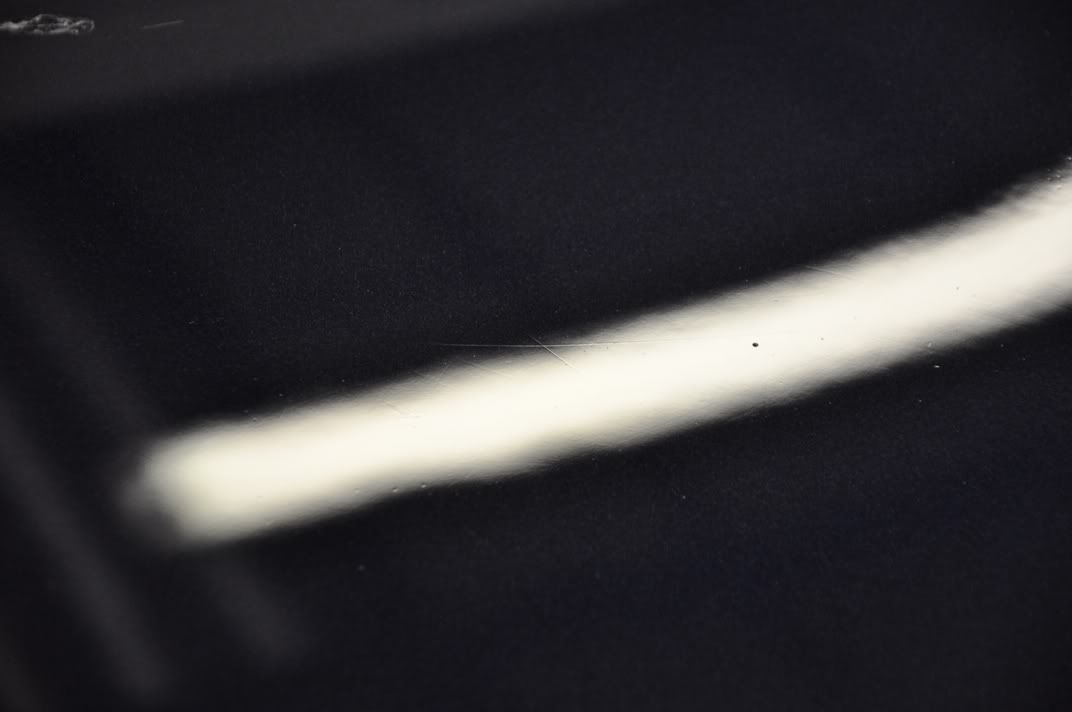

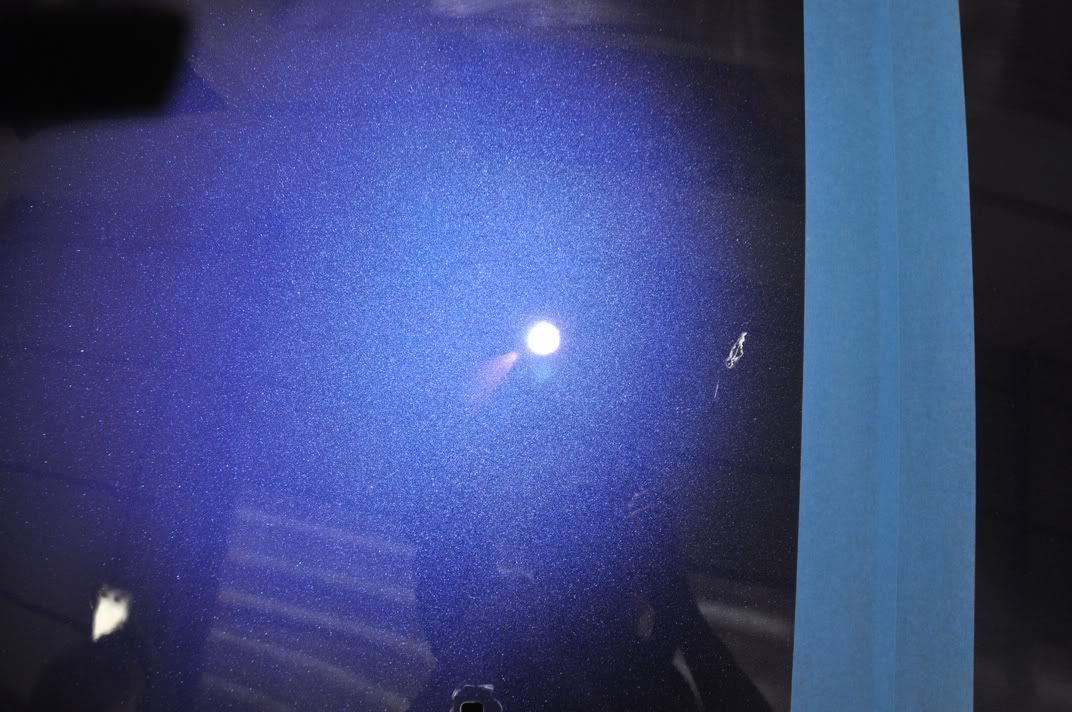

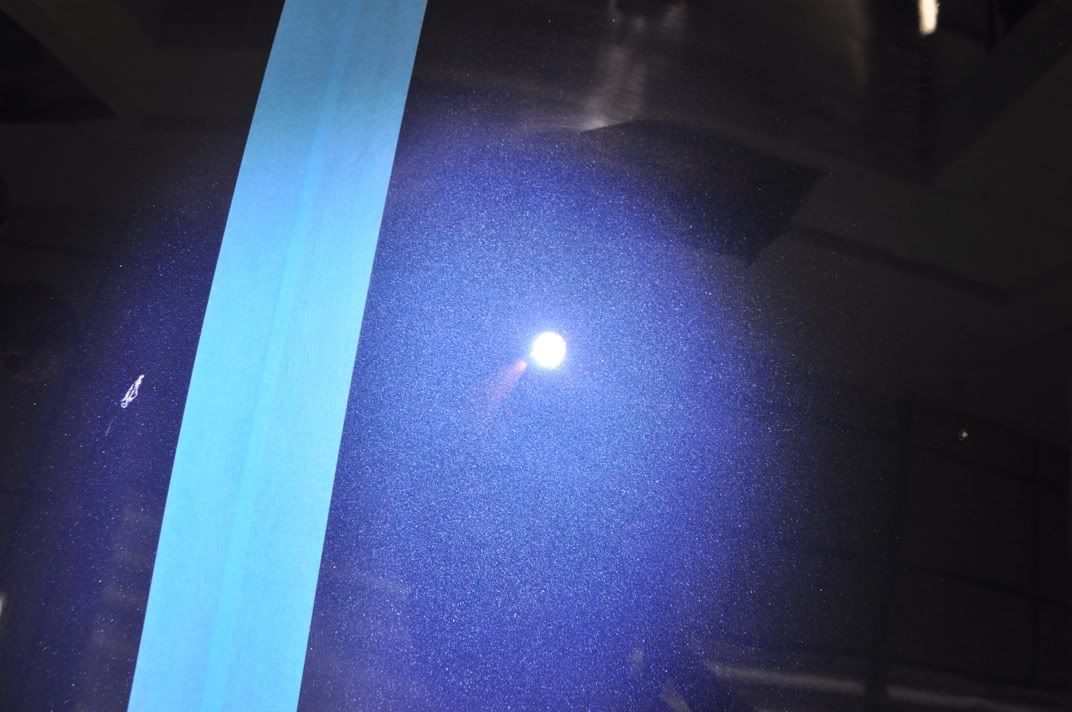

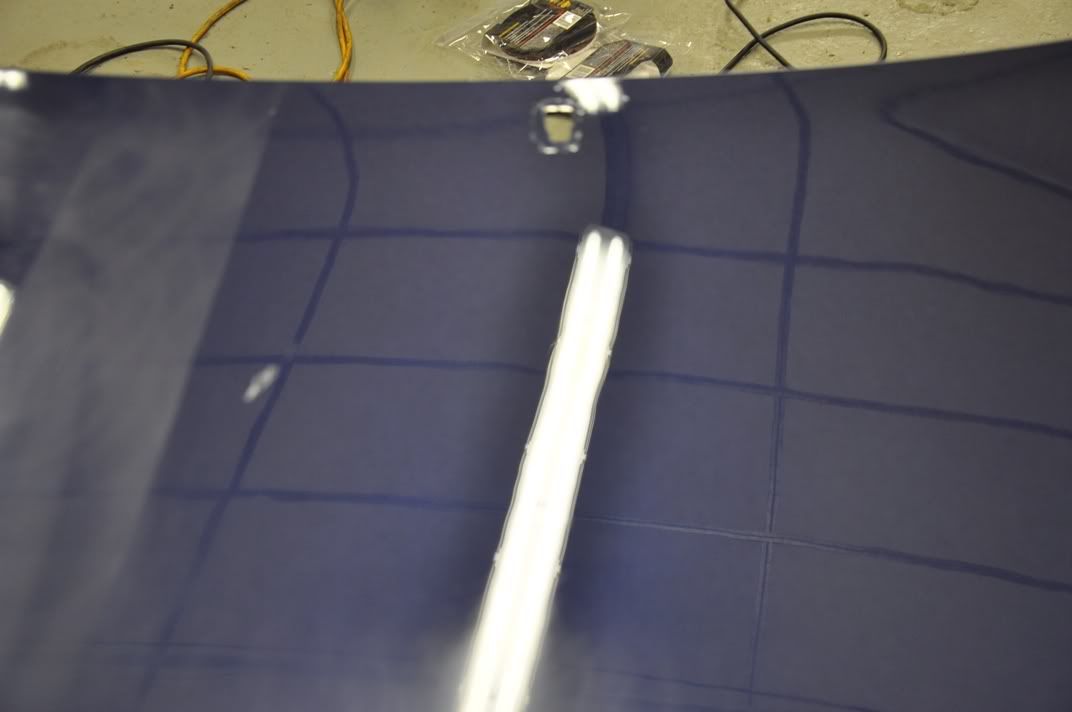

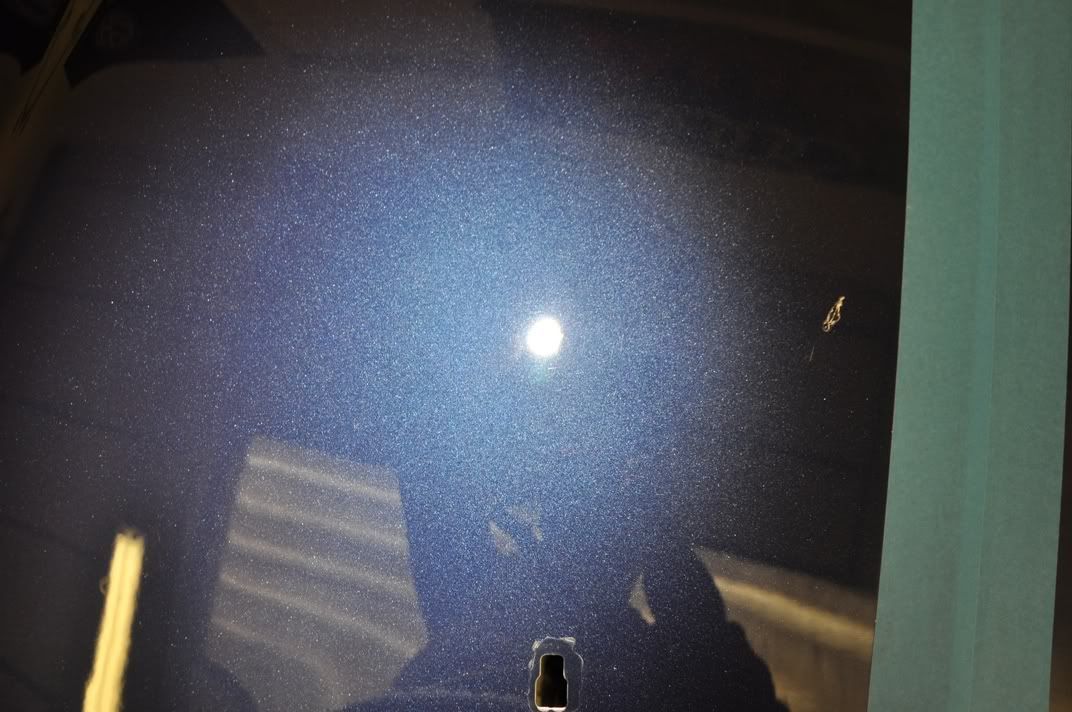

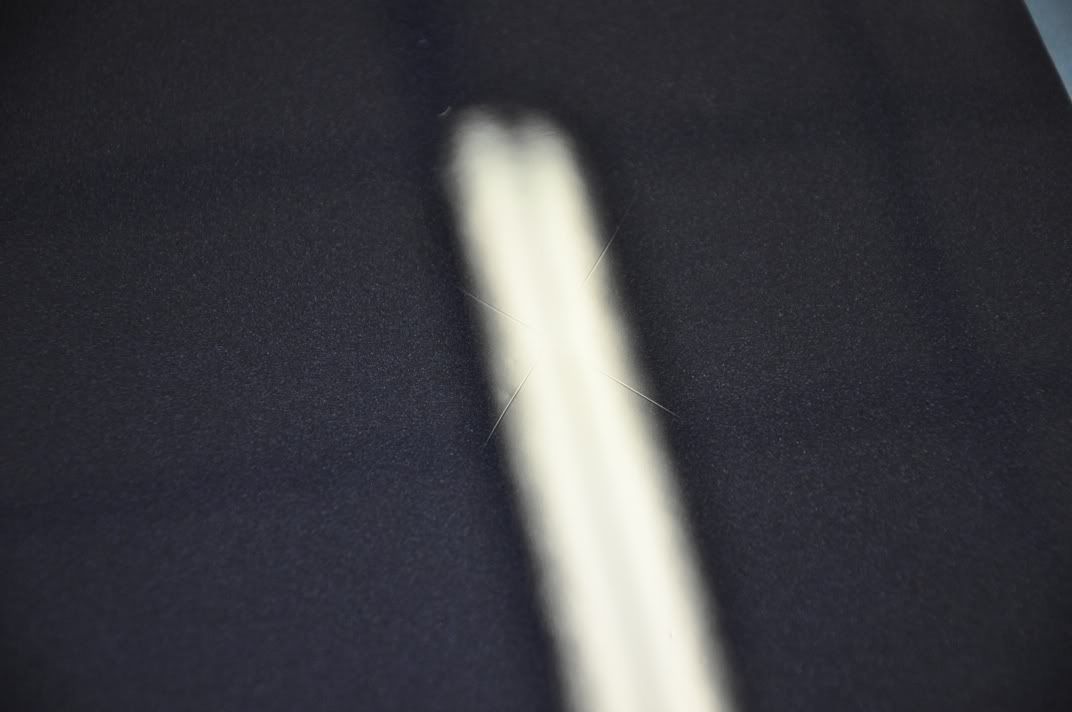

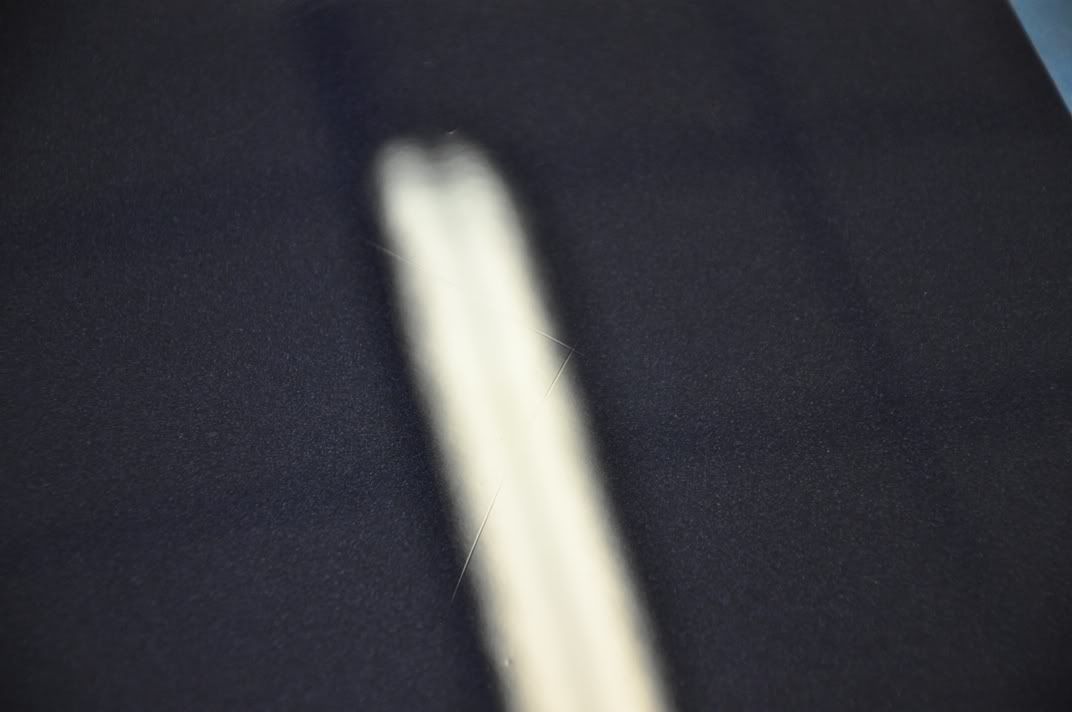

This achieved the following results, first of all viewed under the striplight and the camera focussed on the paint surface to give a true indication of the level of correction of the deeper marks and RDS (look for the X marks the spot):

The Power Gloss seems to have dealt very well with the deep RDS, with little evidence of being there, however the paint still haze a hazy small peel effect to it, so the clarity is not great. Still to be refined of course. Under the Sun Gun:

The finish looks good in terms of correction, with very little of any of the defects left (yes, a DA can correct by foam). A hazyness under the light is to be expected from the cutting compound and pad combo, and will be refined. This sets the bar very high for the new system, as this set does show just how capable a DA with cutting foam can be!

Meguiars Correction Compound on Meguiars DA Microfibre Cutting Pad

So, with the bar set high, the new microfibre cutting pad and cutting compound were used to challenge it. The video below shows a typical set, longer than recommended by Meguairs in terms of passes and at 3.5 minutes this was pretty much the longest sets we would go for on the basis of what the product was achieving and the lack of any benefits of working longer. We will be investigating the effects of water to revive the product and comparing the set times in a later test, but this is how it was performing most strongly for us so far so we used this for the test. Spread at speed 2, and then worked at speeds 4 - 5 on a G220 V2. Note in the video the very slow hand movements (slower than with the foam) and the heavier pressure being used with the microfibre pads which we saw giving benefits in terms of correction:

âªDSC 0025â¬â - YouTube

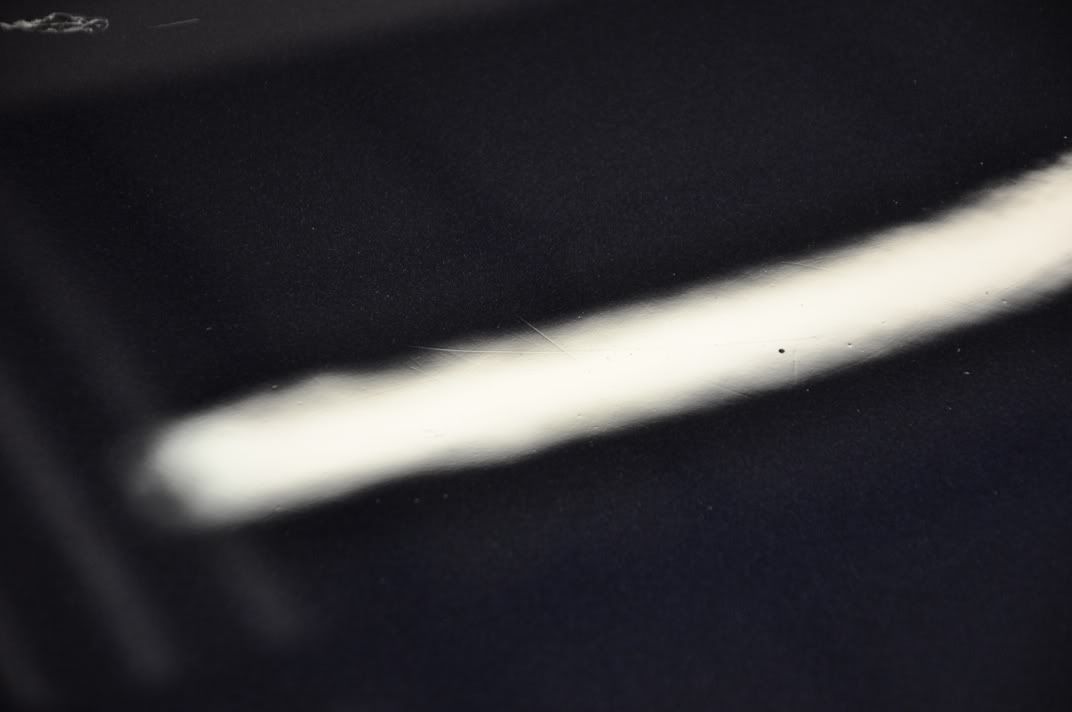

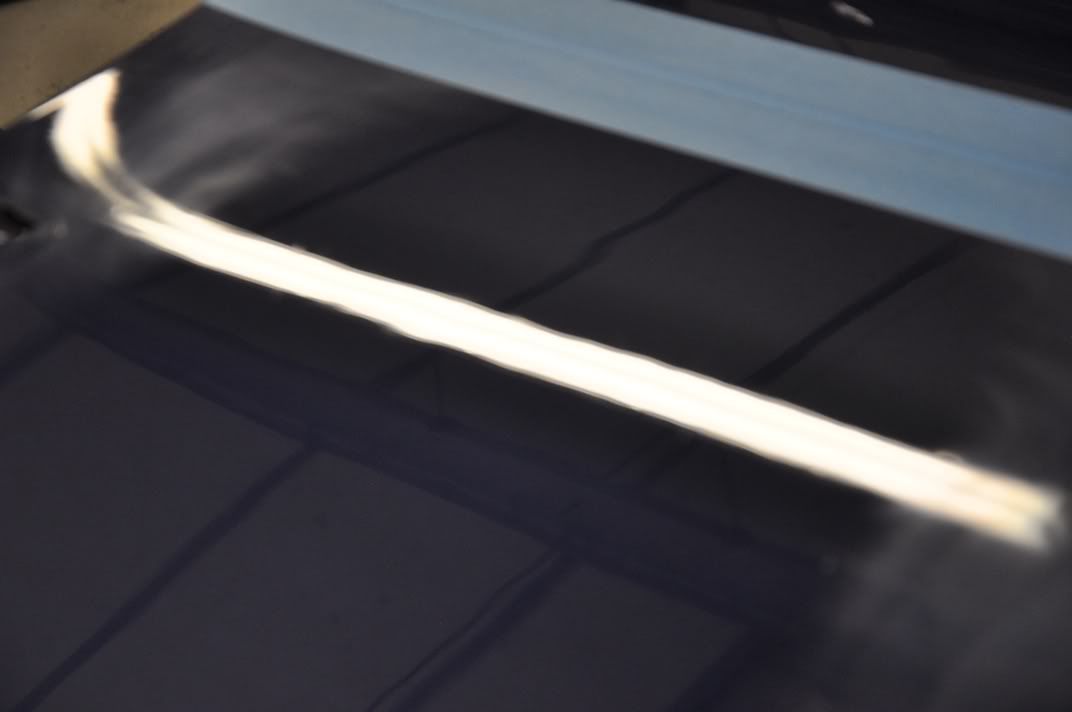

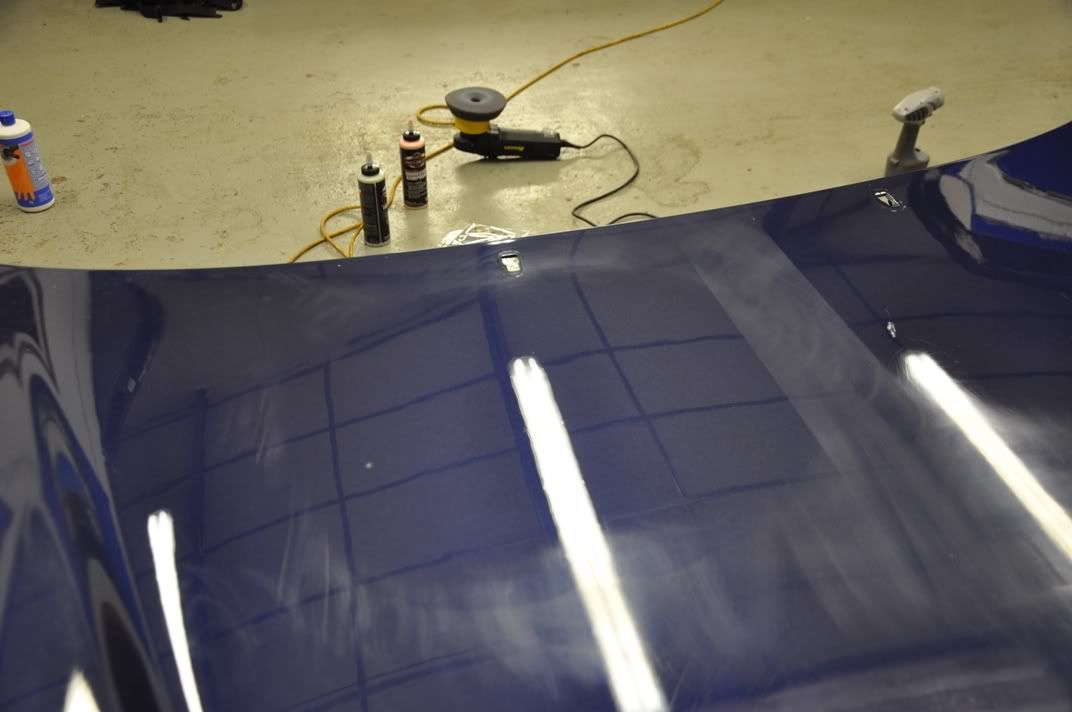

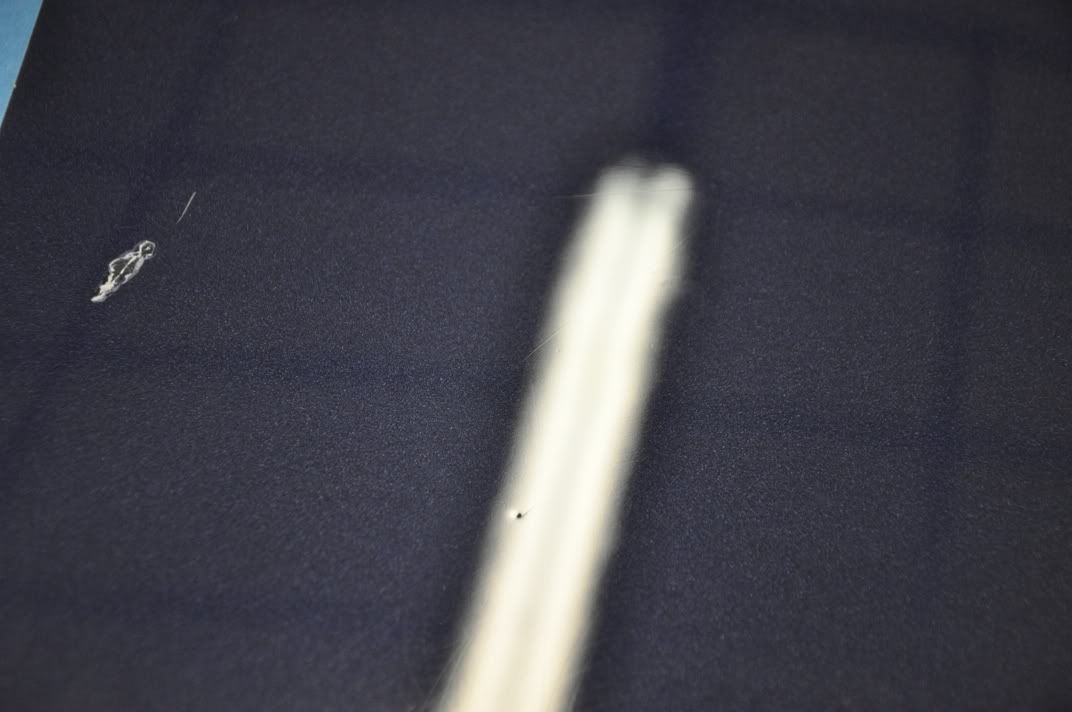

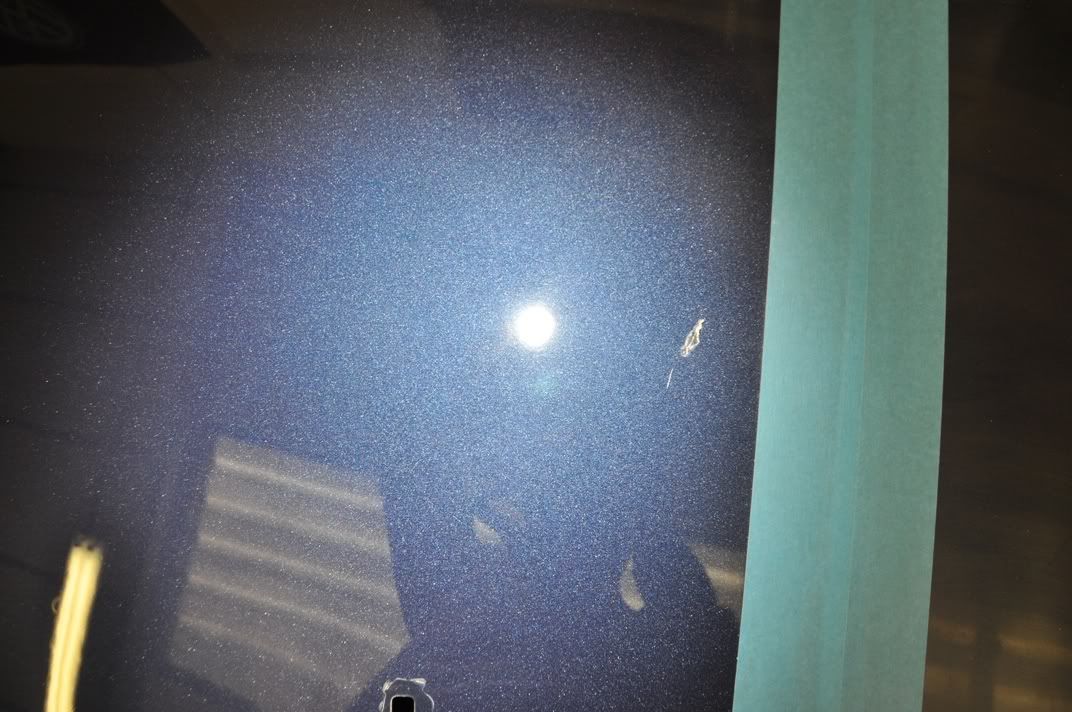

The end results of this, assessed first of all using the strip lights:

Interestingly here, in terms of the RDS we saw less correction than with foam! You can see the X more clearly, but what we also saw was the hazy small peel effect was better removed by the microfibre as if the microfibre system is better at "re-levelling" the paint while actually removing a little less paint than an aggressive foam combination. The correction is not greater, but rather is is of a different style. Under the Sun Gun:

Correction here is excellent, most of the defects are removed and the only remaining were the deeper RDS. Again, this re-levelling shows as the finish seems to have greater clarity straight after this correction compound stage and the shorter sets would be a time saver.

Clarity Comparison

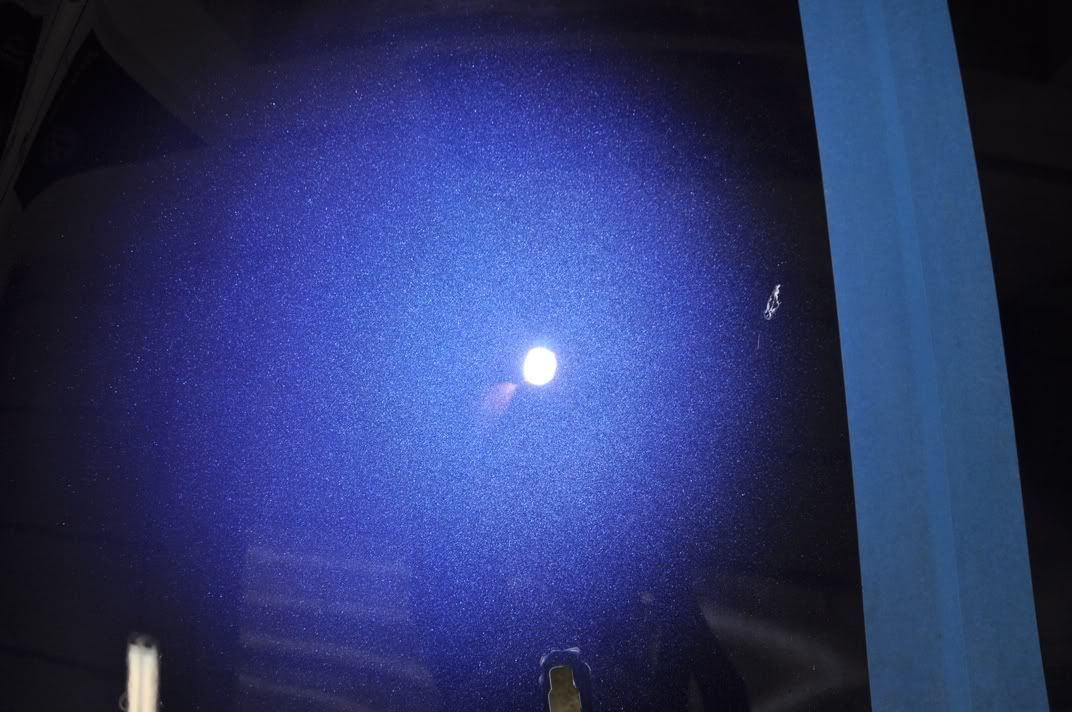

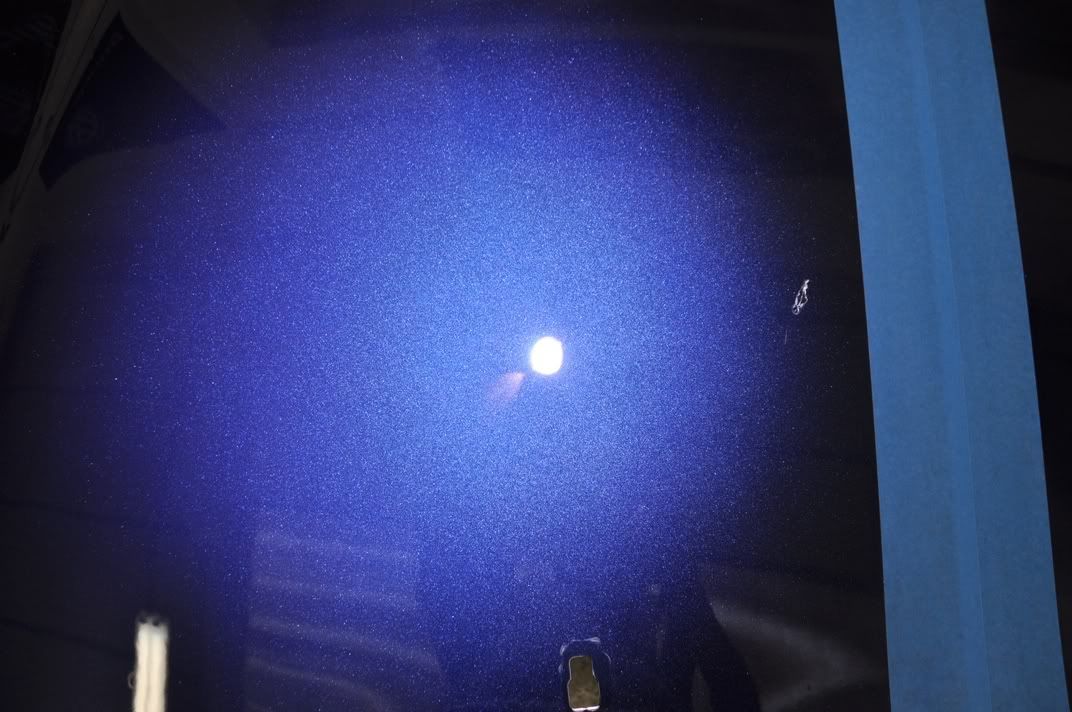

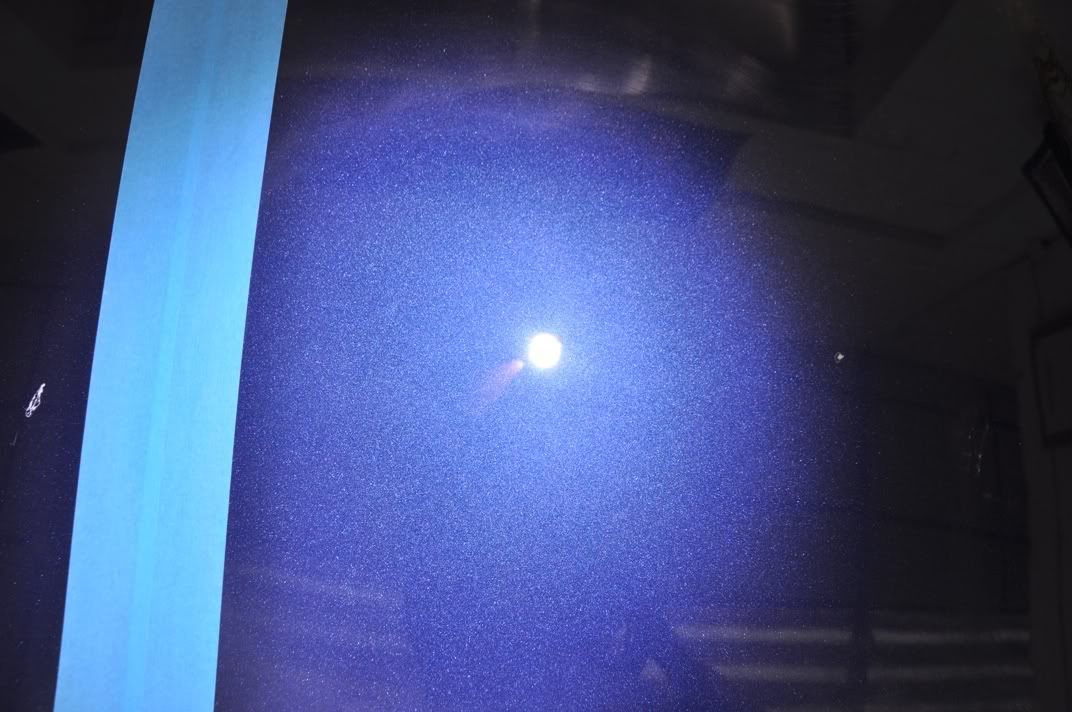

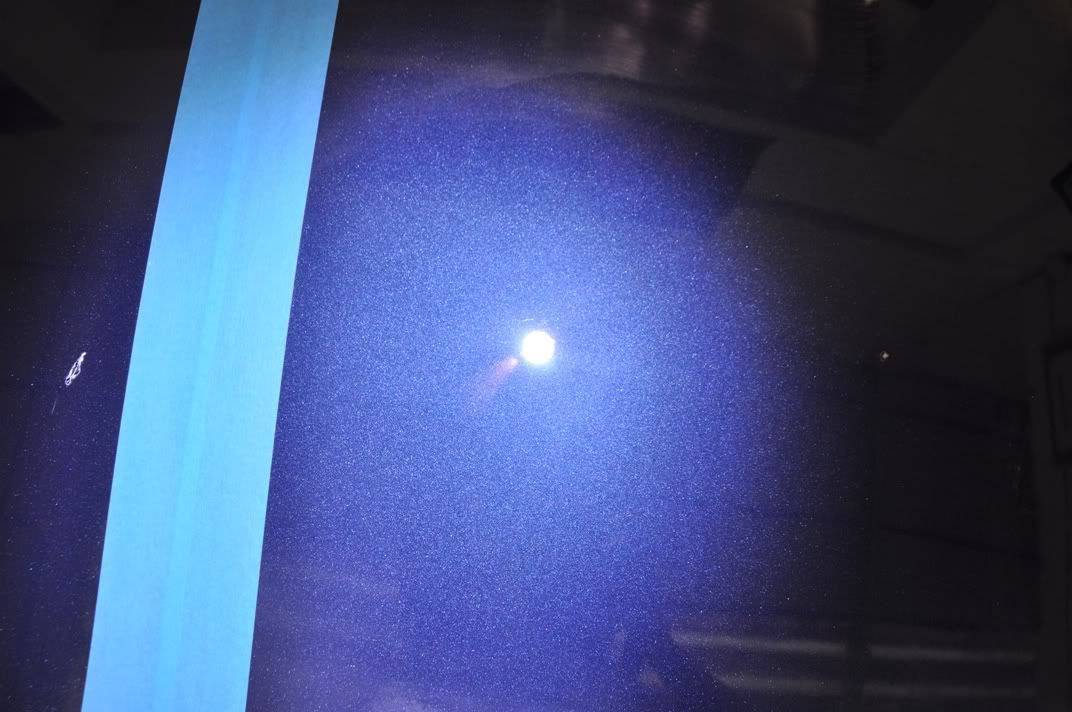

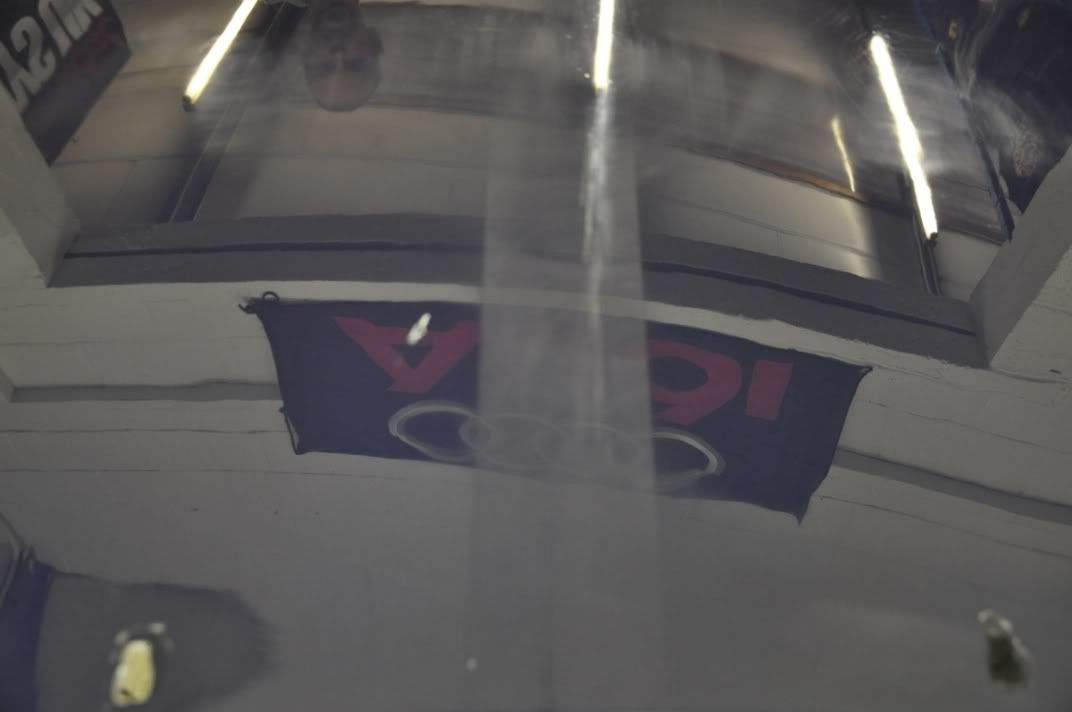

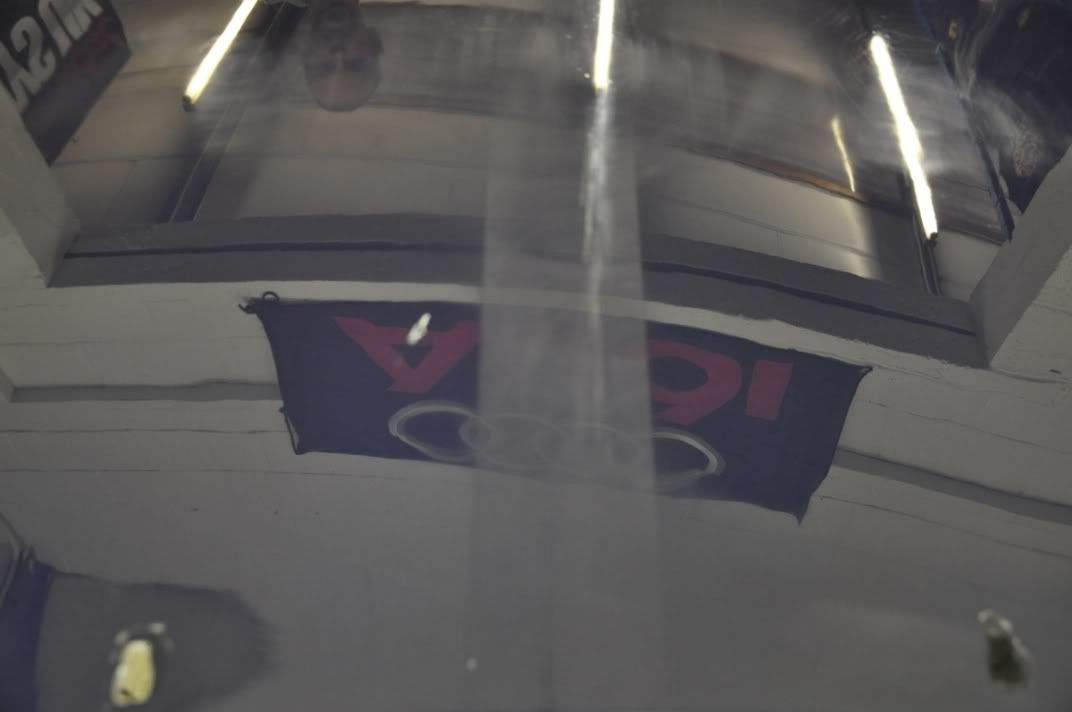

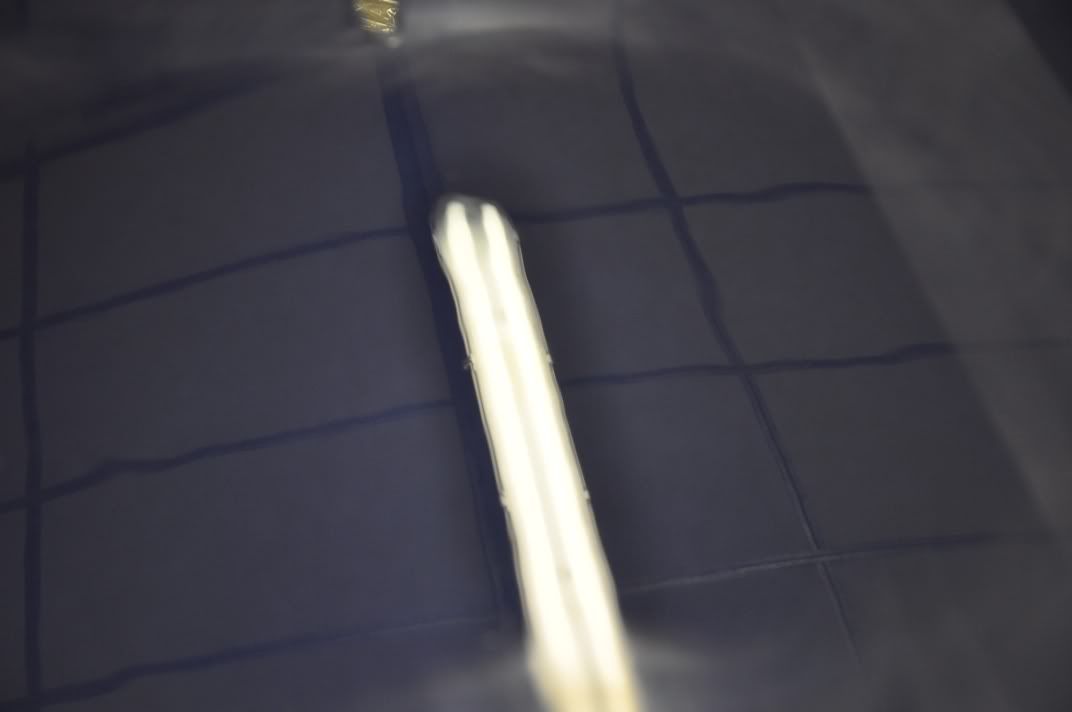

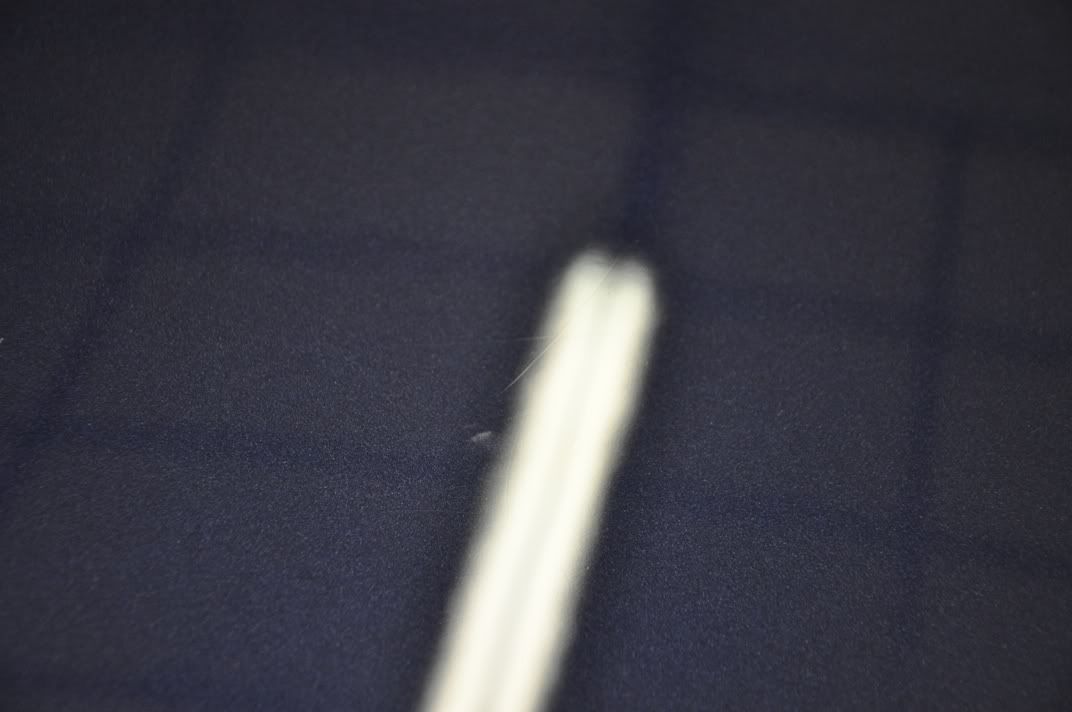

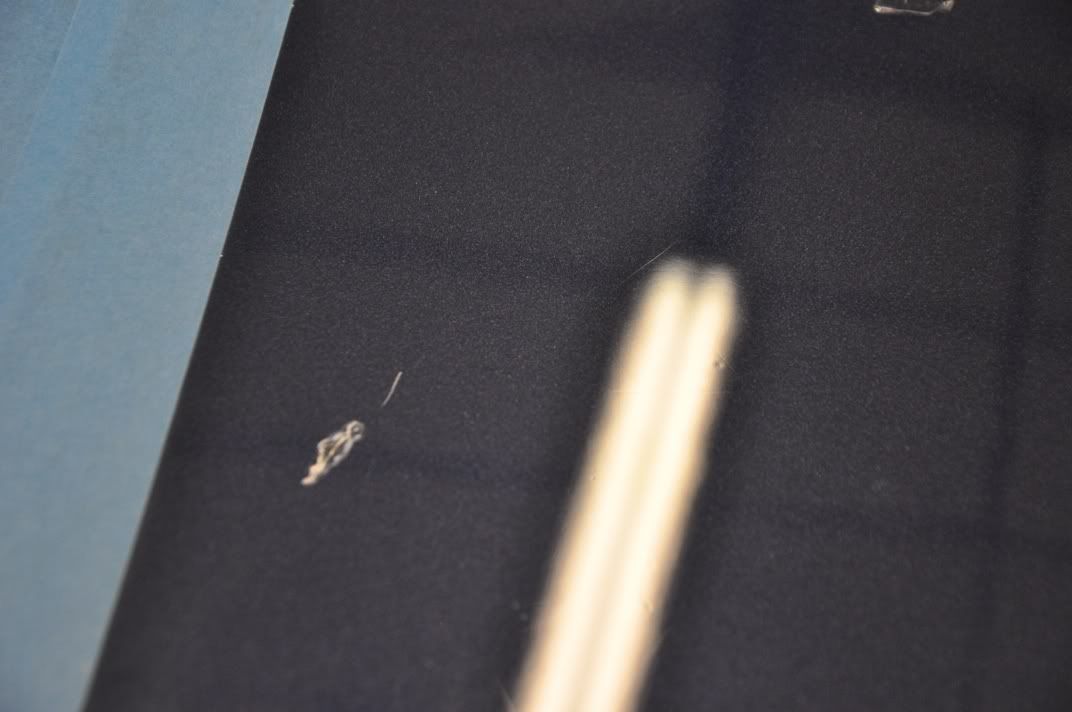

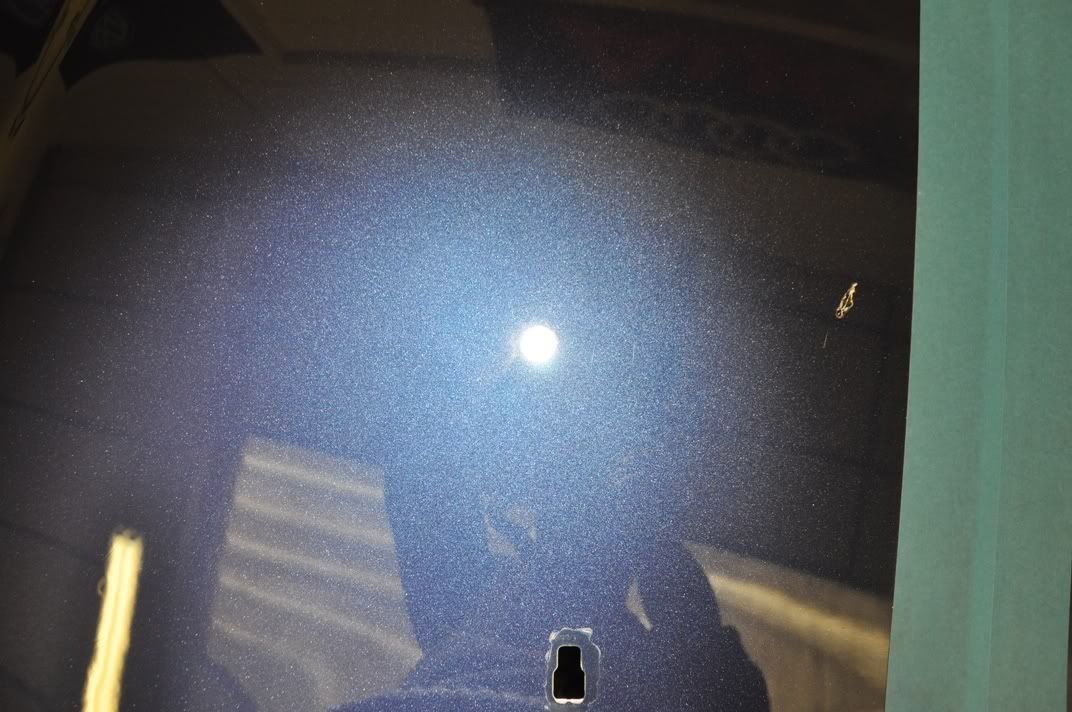

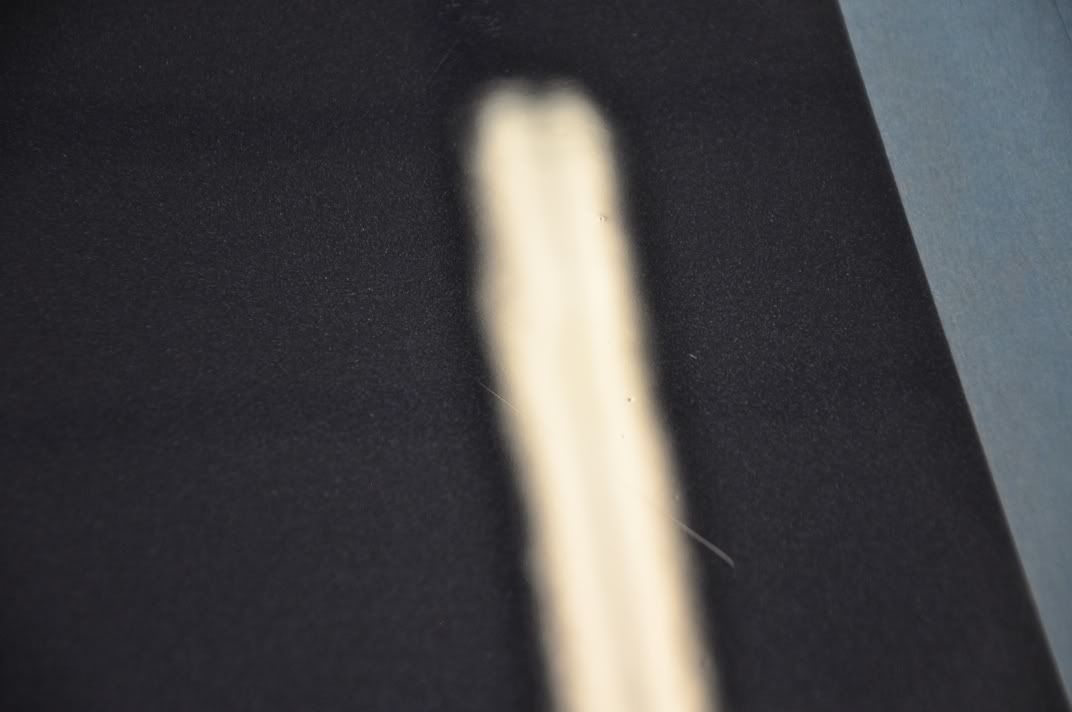

To investigate this idea a little further, we tried to show by photographs the differences in clarity we were seeing by eye between the Menzerna and Meguiars sides. First of all the Menzerna side:

and the Meguiars side:

Arugably, the clarity on the Megiuars side seems to be superior with a sharper and clearer reflection being given. The Meguiars compounds seem to product a slightly sharper finish by making the paint more level than the Menzerna and foam combo which removed more paint to remove the deeper marks more successfully. The correction style is different, both effective but for deeper marks, foam still seems to be in front but for clarity, general correction and saving time, Meguiars has got the edge.

Results 1 to 15 of 18

-

07-29-2011, 05:54 PM #1"A thing of beauty is a joy for ever: Its loveliness increases; it will never pass into nothingness; .... "

-

07-29-2011, 05:55 PM #2

Refining - Menzerna PO106FA on Hexlogic White Polishing Pad

You may wonder why we are not using Menzerna`s finest polish (85RD/E) on a finishing pad here, but given the compound marring left it was decided to refine in two stages for a fair test to the microfibre system and to ensure compound marring is removed is is necessary to use the much more flexible 106FA on a polishing pad... Knowing that when used correctly, 106FA can finish down beautifully, we were happy to use this but are aware that the use of a polishing pad may be bettered with another set using a finishing pad (see end of test ).

).

So - following the refinement:

Looking a bit sharper. Allowing the camera to auto focus:

And with manual focus to focus on the paint surface for a true assessment of the levels of correction:

and under the Sun Gun to check marring removed, and again to assess clarity. If you are wondering what the strange mark at 8 o`clock in all images is, it is my arm :

:

Refinement - Meguiars Finishing Wax on Finishing Microfibre

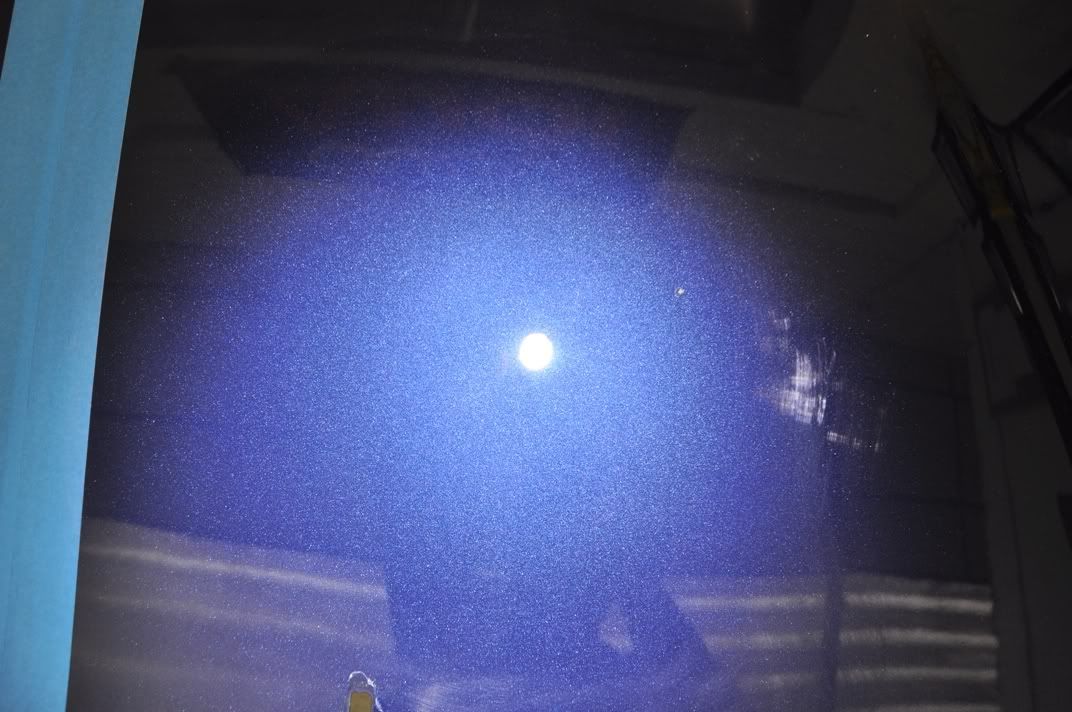

Again, extending the set length beyond Meguiars` recommendation we found that the product refined a little better in terms of marring left, and so we worked the product for two to three minutes on speed 4 on a G220 V2 with light to moderate pressure, finishing with light pressure. This achieved the following results for clarity of reflection:

Allowing the camera to auto focus:

Focussing on the paint surface:

And under the Sun Gun:

The thing here is there seemed to be less of an improvement using the Finishing wax than there was with 106FA - the Menzerna and foam needed the additional stage whereas the Meguiars system seemed to benefit only very little from this additional finishing stage... the overall clarity of the Meguiars seems a little greater, and looking in detail at the above pictures we believe this is because of the levelling effect the compound has to achieve the clearer reflections.

Final Foam Refinement: 85RD on DRC1000 Finishing Foam

Just to give the foam combo every opportunity to refine at its best, we then used a finishing pad (DRC1000 black) and Menzerna PO85RD Final Finish... initially we used the DAS-6 Pro for this but as this video illustrates we had pad bogging issues (foam pad too soft and large for a DA to use comfortably):

âªDSC 0055â¬â - YouTube

So, the Cruise Control feature of the G220 V2 was brought into play to allow the test to be completed with this pad, as it kept the pad rotations...

âªDSC 0086â¬â - YouTube

âªDSC 0087â¬â - YouTube

The results of this final refinement:

Arguably a slight improvement in clarity again and coming closer to the Meguiars side.

Finish Comparisons & Conclusion

Below, we show comparisons of the finish, first of all side by side, with Menzerna on the left and Meguiars on the right of the uncorrected line:

Menzerna side after:

Meguiars side after:

On the test, it seemed that the Meguiars side had the greater clarity and slightly sharper reflections which seemed to be down to the first stage of the process where the Correction Compound did a superior job of levelling the surface despite not fully removing the RDS - the correction style seems very different and this has advantages in terms of the clarity but disadvantages in terms of outright correction. Perhaps, it would be fair to say that both systems have their place rather than one taking over from the other. Meguiars certainly have introduced a new and exciting range here and the combo of pads and polishes/compounds is impressive and produces very good results, and when time and clarity are considered as well as correction you see the big plus points for the products. More testing to come, but so far, Meguiars` new DA Microfibre system is impressing :thumb:

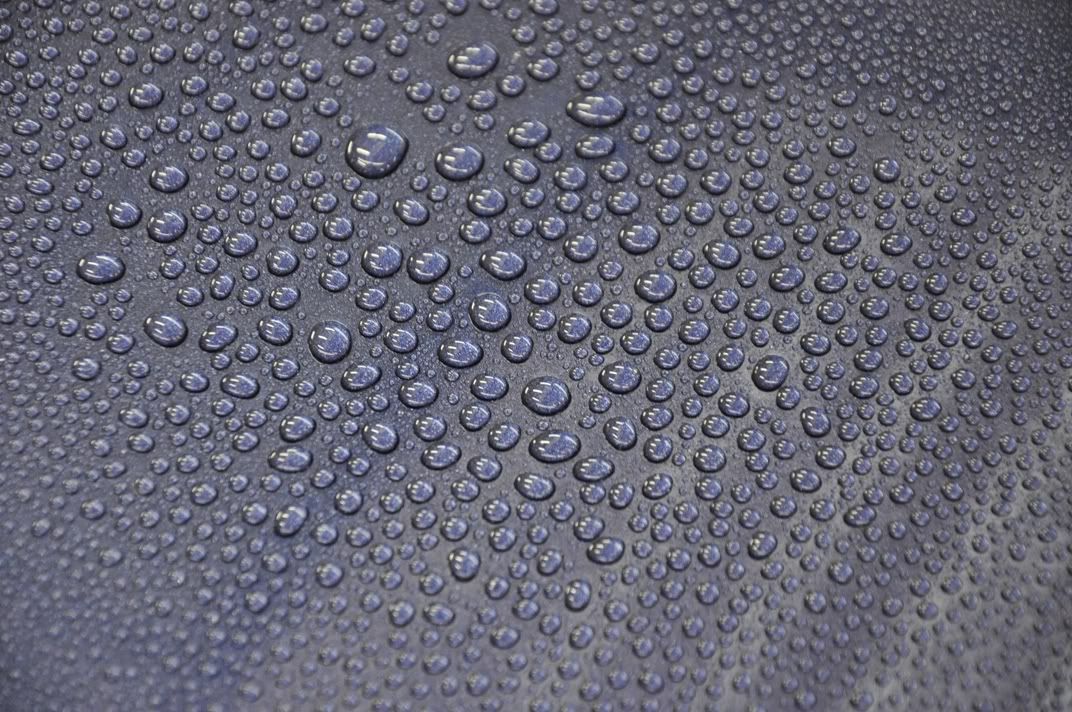

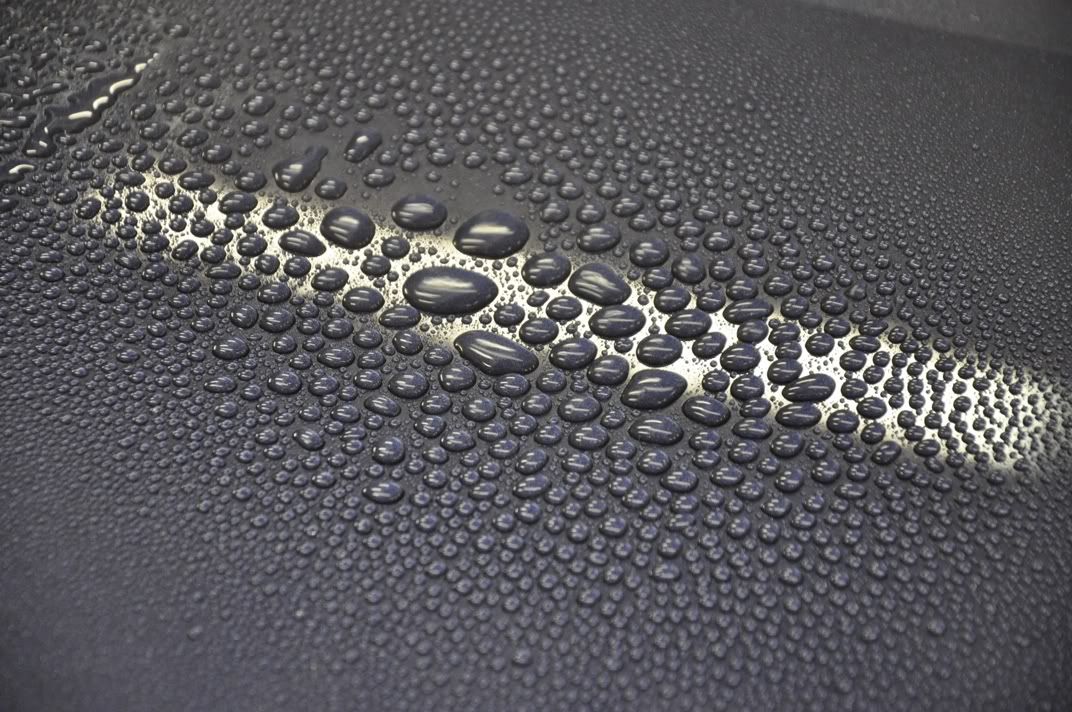

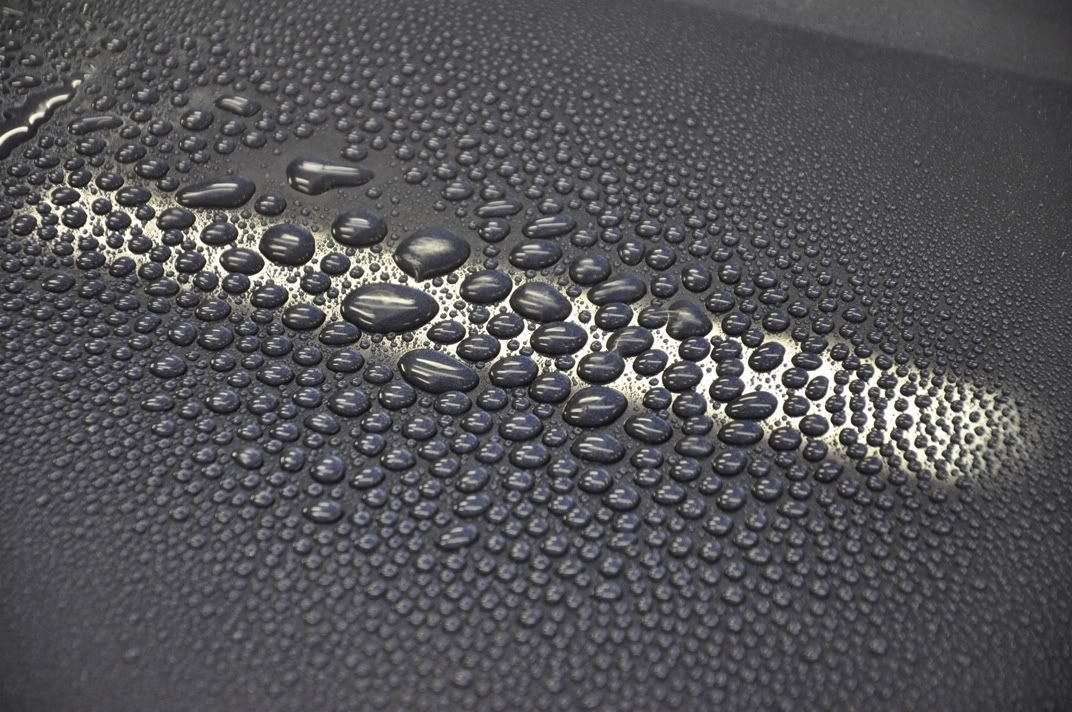

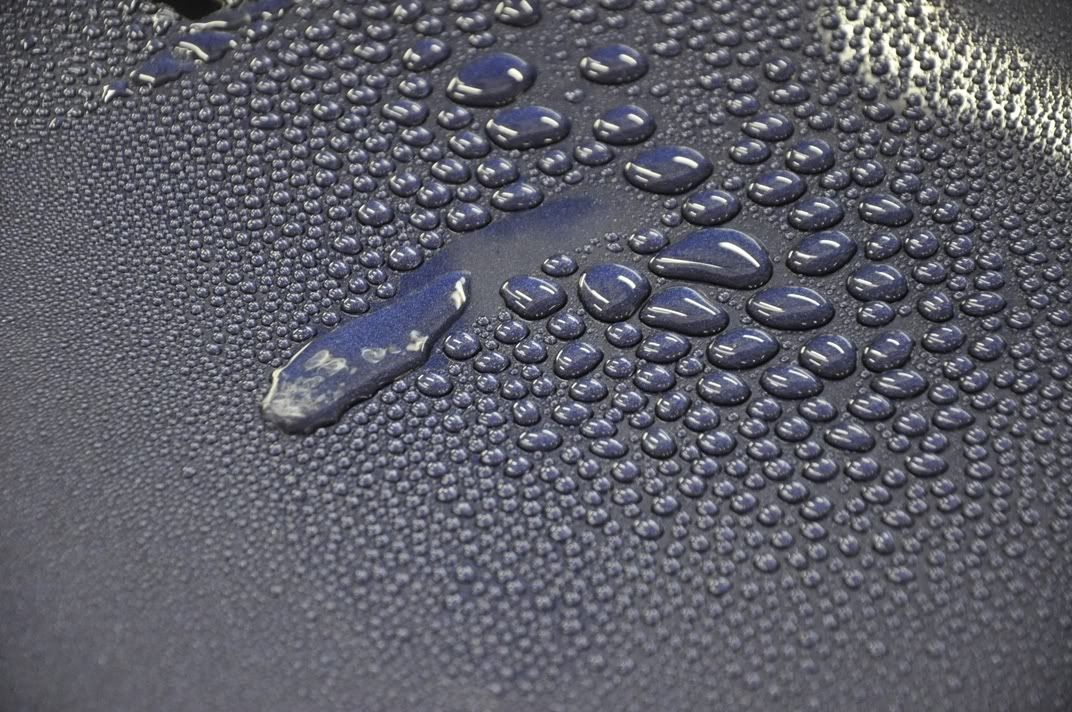

Finally, some water bead shots showing the beads growing in size with more water added until the bead finally breaks free. Results from the finishing wax:

"A thing of beauty is a joy for ever: Its loveliness increases; it will never pass into nothingness; .... "

"A thing of beauty is a joy for ever: Its loveliness increases; it will never pass into nothingness; .... "

-

07-29-2011, 08:18 PM #3

Excellent comparison. One thing that I really haven`t heard much on is the durability of the MF pads compared to foam.

-

07-29-2011, 09:19 PM #4

Great write up. I recently purchased the microfiber system, and a Griots polisher so I could try this system out. Although I thought the clarity was pretty good, it lacks correction ability IMO. A great product none the less, especially for the home user.

John

-

07-29-2011, 09:45 PM #5

Any chance in throwing in M105 with the Microfiber for comparison?

-

07-29-2011, 10:35 PM #6

I`m with Matt, can you use 105 to get a better correction?

-

07-29-2011, 10:53 PM #7

Originally Posted by Matt_H

Originally Posted by Matt_H

Originally Posted by MobileJay

Originally Posted by MobileJay

I used the MF System and D300 for a 1-step polish because that was all the customer`s budget allowed. In reality, the black Lincoln could have benefited from 105/rotary and a 2nd refinement step. The MF/D300 finished well enough to go straight to LSP. On some of the stouter defects where I thought I`d have to spot with PFW/105 a couple of dots of D300 with a couple of dots of 105 added to the MF pad removed the defects with no dusting and much longer working time than 105 alone. Finished just as well as the D300 alone as well.

Great comparison, Dave! I was missing your posts before you resurfaced. :xyxthumbs

TL

-

07-30-2011, 05:09 AM #8

Great test as always, Dave!

Have you ever used the Fast Gloss S500 from Menzerna? It´s so much better then POS100. I would guess that you could have gone from S500 straight to APO60 (sealing wax) wich is a little bit tweaked now.

-

07-30-2011, 09:30 AM #9

-

07-30-2011, 02:44 PM #10

Personally, while I appreciate Dave`s efforts in the testing, I think its not really fair. Yes, quite a few of the menzerna products can work and do work with a da, but they were not all designed to do their best via da. And these products are being put head to head against a system that is purpose built to work with a da.

With all that said, I do wonder..

What kind of results could have been seen if the menzerna was used with the mf pads? and the megs products were used with the foam? What kind of results could either group of products have been seen with the addition of surbuf for the correction step?

-

07-30-2011, 05:06 PM #11

Originally Posted by usdm

Originally Posted by usdm

The microfiber pads work well with pretty much every buffing liquid I`ve used them with.

Their design offers up a lot of surface area to which abrasive can attach to, versus a typical foam pad. Add in the fact that the fibers are very thin- so much so, that they don`t typically leave marring that is visible to the naked eye. This is a main reason that they work well for cutting and final polishing.

We were using the prototype discs with M86 and M105 way before D300 compound was created.

And... the guys at the OEM level were using them way before us, with an unknown to me compound.

So, I agree with you that results can change dramatically depending upon the combination.

That being said.. it is difficult to create a test that covers all combinations, and Dave KG is known to be among the best when it comes to unbiased testing. With a background in Physics, he is a gift to the community.

Can he do lots of things to optimize performance of the discs and the compounds as they are paired?

Yes, but he is a methodical guy, and I suspect we`re going to see many more tests and opinions on the system from Dave.

Sounds corny, but.... these discs are akin to a race car.

Toss a rookie driver behind the wheel, and he`s bound to go pretty darned fast because the car itself is very capable. If however, you throw an experienced professional driver behind the wheel, he is certainly going to annihilate the rookie`s abilities using the same car.

These discs are among the most capable of buffing pads ever created.

Tweak the buffing set-up (backing plate sizing and flexibility, machine, stroke, etc.), and the procedure (speed setting, pressure, backing plate rotation, arm movement, amount of compound, supplemental wetting agents, etc.), and you`ve got the makings of an incredibly versatile and capable buffing weapon.

In short, give them a whirl with whichever compound, polish, or wax you wish to!

-

07-30-2011, 08:24 PM #12

Great test Dave, and I think Kevin nailed it too. I have experimented with the MF pads and other polishes and results (IMHO) are better than with foam pads. I have found that 1500 grit sanding is easily polished out with the MF cutting pad and UNO v3.

All I have in this world is my word, and my balls and I don`t break `em for no one, you understand?"

-

07-31-2011, 01:58 PM #13

Originally Posted by yakky

Originally Posted by yakky

Interesting that you mentioned, the velcro of my MF pad come off half way through on my 3rd car. Is it normal or am I doing something wrong?:think:

-

07-31-2011, 03:44 PM #14

Originally Posted by dschia

Originally Posted by dschia

Not normal. :grrr

It is happening here and there, and they`ll want to be sure to replace it.

Give Meguiar`s Customer Care a call, or the place you purchased them from.

Don`t toss it out - they may want to inspect it for their own purposes (not to confirm it was faulty prior to replacing).

-

07-31-2011, 08:01 PM #15

Originally Posted by Kevin Brown

Originally Posted by Kevin Brown

Customer Care replaced one of mine with a fresh 2-pack, no return necessary. If the velcro separates near the edge you may want to consider using a 4" pad for a template and cutting it down. I`ve found a 4" size pretty handy. YMMV.

TL

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Meguiars DA Microfiber Correction System

By dschribs in forum Car Detailing Product DiscussionReplies: 0Last Post: 10-14-2014, 10:05 AM -

REVIEW: (Product Showdown) Head to Head review of 4 products: 2 tire gel and 2 tire dressing

By Dr_Pain in forum Detailing Product ReviewsReplies: 22Last Post: 06-01-2014, 09:27 PM -

Looking for a good clean buffing system Wools/Foams/Compounds - My head is spinning!

By 777funk in forum Car Detailing Product DiscussionReplies: 0Last Post: 03-24-2012, 12:19 PM -

Meguiars Microfibre DA Correction System - My Initial Test & Thoughts

By imported_Dave KG in forum Machine Polishing & SandingReplies: 3Last Post: 07-17-2011, 04:06 PM -

#16 and CMW in a head to head competition

By Scottwax in forum Car Detailing Product DiscussionReplies: 26Last Post: 11-09-2004, 08:36 AM

Reply With Quote

Reply With Quote

Bookmarks