This is just a quick thread to give an initial flavour of the new Meguiars Microfibre DA correction system, which I will be testing over the coming weeks in a variety of different tests.

So - my first introduction to microfibre being used with a DA for correction was with the Chemical Guys microfibre pads and using V36/38 Optical polishes, the latter not being specifically designed for use with microfibre but despite this they worked very well... So this was to be the benchmark which I would measure the Meguiars against, as well as comparing to correction by foam and on the rotary (subjects of future threads).

One of the things that struck me when reading the bottles of the products (Correction Compound and Finishing Wax) was the short working time suggested, as I for one am a fan of long work times to ensure the product is fully worked... but this gave me an idea for the first part of the testing - if the work times are short, then this lends itself to ease of use on a sunny day where long work times are not always possible because the heat can dry out the product. So, to put this to the test, take one sunny afternoon (rare summer weather!), and a red Astra with moderate defects and hazing.

The bonnet of the test car before...

Now, the Meguiars system comes with two different pads and products: a cutting microfibre and a finishing microfibre, and a cutting compound (Correction Compound) and finishing product (Finishing Wax) which combines refinement and the waxing stage... On this panel, I decided to start off with the Correction Compound on the cutting pad. The cutting pad has stiffer burgandy foam supporting the microfibre:

Applying the correction compound:

Priming the microfibre by massaging the compound into the microfibre pad...

Additional working compound added:

A lot of product is used at this stage, but then you only need a couple of beads to top up between sets in testing. Between sets it is also essentially just to use your fingers to ruffle the microfibre back up so it doesn`t clog and lie flat.

Application was with the new G220 V2 (separate thread on my thoughts on this to follow), spreading the product over a 1` square area at speed 2 and then working the product on speed 5. Working was with firm pressure, between 10 and 15lbs, and with very slow hand movements (slower than typical for foam at less than 1" per second)... only six or seven passes were made over a two minute period with the product before switching the machine off. This seemed like a very short set, but the residue had gone clear at this stage and in the sunlight the finish appeared to be corrected and quite well refined... The results after a short set with the compound:

I was impressed as the short work time still gave significant correction and to my eyes very good finishing as well with no micromarring evident and a nice gloss with good clarity. Still the finishing stage to go. The abrasive style of the new Correction Compound seems to cut hard and break down quickly so it gets the correction quickly before breaking down to refine so you need less work time, which was handy in this direct sunlight! Longer work times will be experimented with in due course, but these are the results roughly following the instructions on the bottle

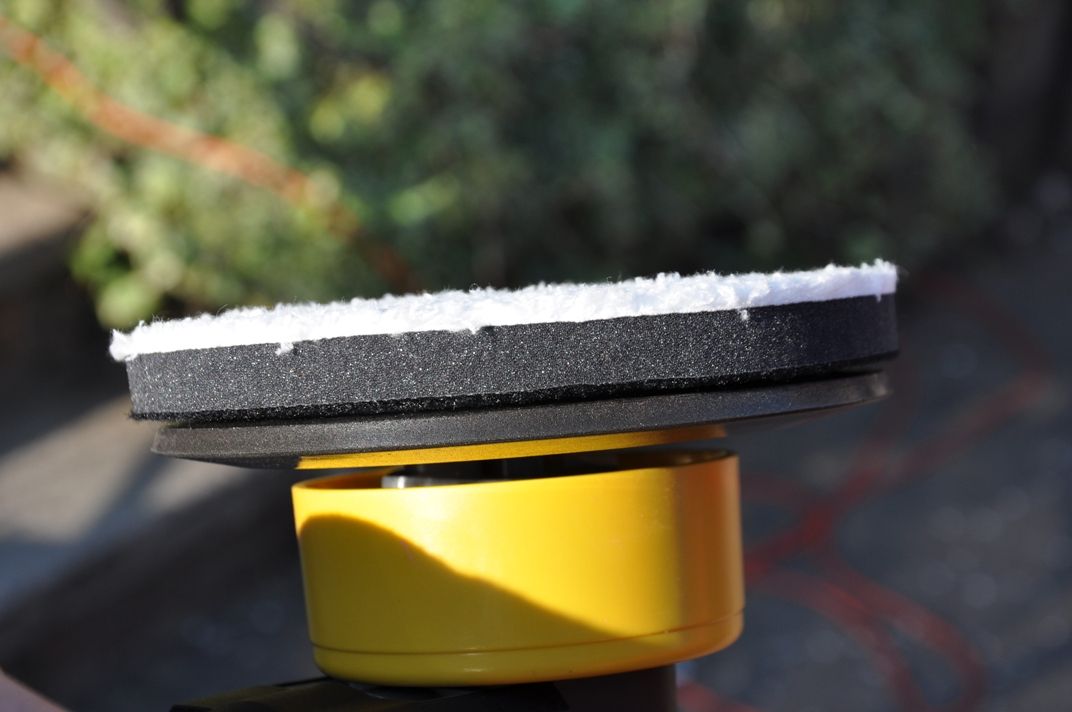

Anyways, with these results, it was time to refine the finish using the Finishing Wax on a finishing microfibre. The difference between the two microfibre pads is the supporting foam, and the finishing pad has got softer black foam supporting the microfibre:

Applying the Finishing Wax, the pad was primed as above:

Spread at speed 2, worked at speed 4 for a couple of minutes again - this time using lighter pressure (5 - 10lbs) but still slow hand movements. This product seemed to have a longer work time, but I stuck roughly to the short work times for this test and will look at longer work times in future tests. The residue buffed off with real ease, almost as easy as CG 50/50 wax and this was one thing that really appealed to me. The results...

The clarity seemed very good at this stage, though I reckon it can still be improved upon with longer sets with the Finishing Wax especially, so I will be experimenting with that in due courseHowever, I was impressed with this initial set of results given the speed at which they were achieved in terms of work time. Some more finished shots... Only about one third of the bonnet completed so far:

Now, the Finishing Wax suggests that the job is done at this stage, so I will be testing the finish and durability offered by this product too - so a couple of water tests, showing how the product performs with water: driver`s side of bonnet treated, passenger side just washed and clayed, and you can see a clear difference in the water sheeting, the Finishing Wax delviering decent sheeting ability though for me below what I would achieve using a dedicated wax such as Meguiars #16 (please excuse my dad who was pouring the water on the car who saw the cat that sits on and scratches his car bonnet and digs in the garden - I think he was seeking revenge with the watering can):

Of course, there is nothing to stop you applying a wax after the Finsihing wax to enhance the water beading and sheeting, and as a stand alone the Finishing wax does perform well in its own right.

So - first impressions are very positive so far, the speed and ease of use being big plus points and the results for me speaking for themselves even very early in the testing. This is just the start, so watch this space for further threads as the system is put through its paces

Results 1 to 4 of 4

-

07-17-2011, 08:26 AM #1"A thing of beauty is a joy for ever: Its loveliness increases; it will never pass into nothingness; .... "

-

07-17-2011, 12:45 PM #2

Great write up Dave, welcome to the club. How does CG`s system compare to Meg`s?

-

07-17-2011, 01:35 PM #3

Great info.

I purchased the system and opted NOT to get the finishing wax, thinking I`d finish out with M205 or Ultrafina, but now you`ve made me think I made a mistake.Unemployed Since 2009 - Gibs Me Dat

[SIGPIC][/SIGPIC]

-

07-17-2011, 04:06 PM #4

I also do not use the F. Wax that much. I prefer to use 205 as last polish and then top with Opti Seal. I prefer longevity and it`s worked well for me.

Robert and Susan Regan

Towel Pros Microfiber

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Meguiars DA Microfiber Correction System

By dschribs in forum Car Detailing Product DiscussionReplies: 0Last Post: 10-14-2014, 10:05 AM -

DA Heavy Correction Head to Head: Meguiars Microfibre System vs. Menzerna on Foam

By imported_Dave KG in forum Machine Polishing & SandingReplies: 17Last Post: 08-01-2011, 09:51 AM -

Meguiars microfiber correction system ?

By DRT in forum Car Detailing Product DiscussionReplies: 30Last Post: 06-25-2011, 08:34 PM -

Question about the Meguiars DA Microfiber Correction System.

By 2MnyToys in forum Car Detailing Product DiscussionReplies: 7Last Post: 05-26-2011, 10:41 AM -

Meguiars DA Microfiber Correction System

By imported_Intel486 in forum Car DetailingReplies: 31Last Post: 02-18-2011, 08:46 AM

Reply With Quote

Reply With Quote

Bookmarks