Originally Posted by tdekany

The difference is in how the two machine get their forced rotation. The Flex is basically a random orbital that forces the pad to spin by interfacing the backing plate with the housing. So, the orbit goes one direction the pad spins the other.

The Makita has planetary gears that force the pad to spin the same direction as the orbit which creates more revolutions per minute and more movement between the pad and the paint.

The Festool`s movement is similar to the Makita`s but it`s orbit is slightly smaller.

Robert

Results 16 to 30 of 72

-

04-01-2010, 04:02 PM #16

-

04-02-2010, 03:54 AM #17

Originally Posted by WhyteWizard

Originally Posted by WhyteWizard

I donât know which is more powerful, the Makita or the Flex, because I have very limited experience with the Makita, and only moderate (compared to many others) experience with the Flex.

However there are a couple of points that I think are relevant to this discussion.

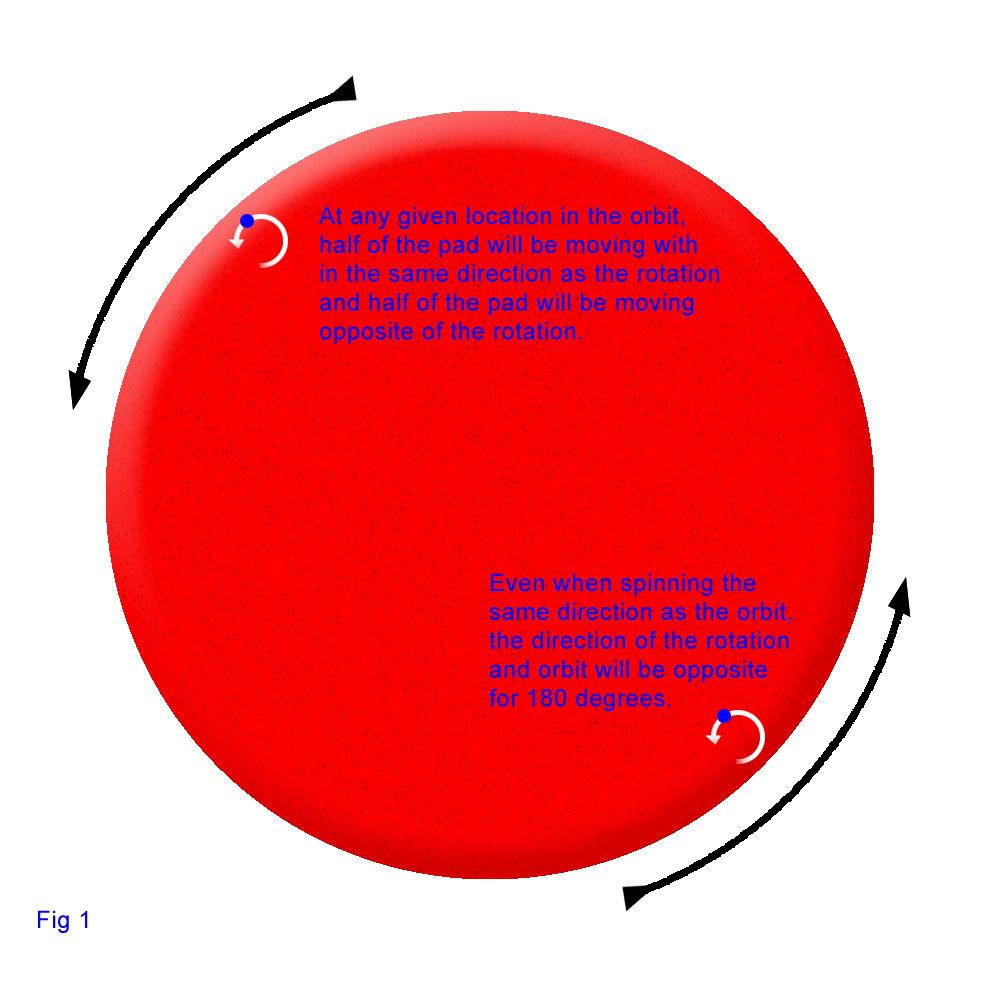

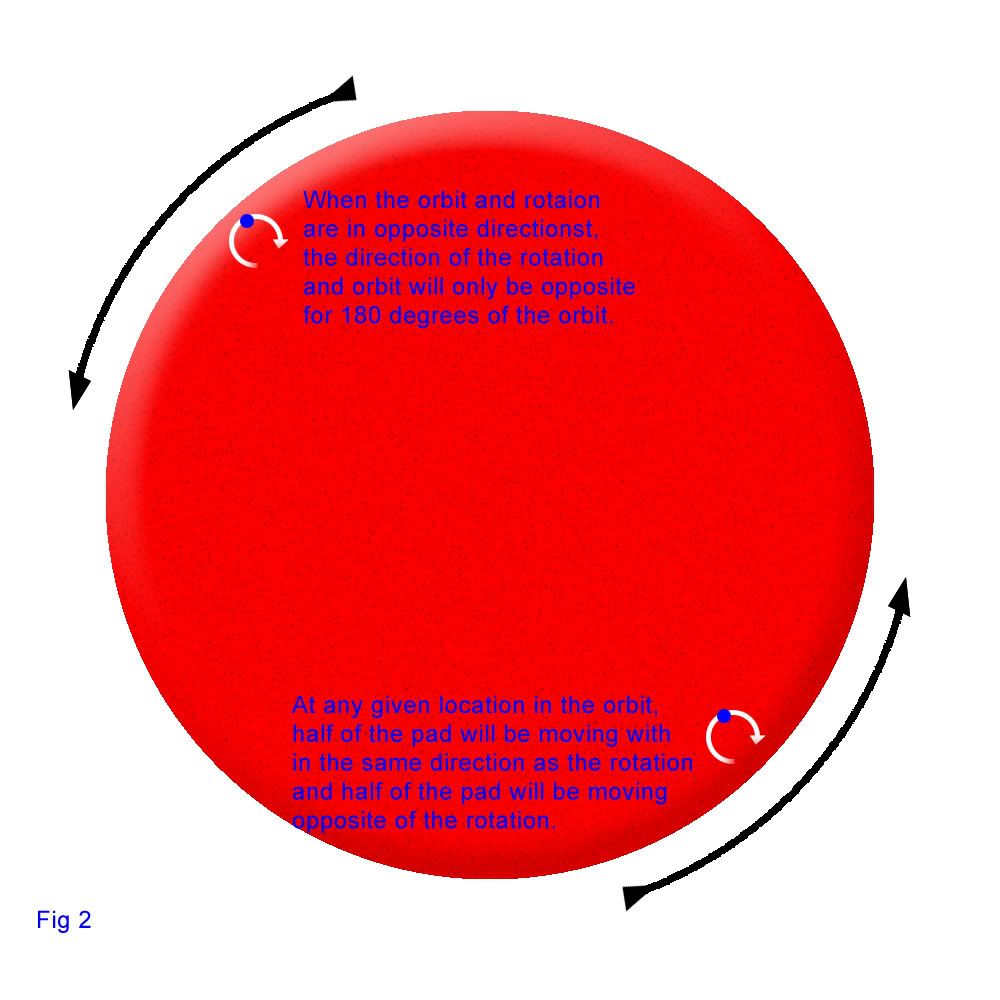

The direction of orbit vs. rotation is really a non-factor when it comes to corrective ability because we are dealing with objects that are moving in 360 degree motions. Even if the orbit and rotation are the same direction (counter clockwise for example) the orbit and rotation will still spin against each other for 180 degrees, depending on which part of the pad you are looking at.

Figure one shows a DA machine which the orbit and revolution are the same direction. Yet at the same point in the orbit (roughly 270 degrees) half of the pad is accelerating with the orbit BUT the opposite corner is moving against the orbit.

Fig two shows a DA machine in which the direction of the orbits and revolutions are opposite. Because we are dealing with 360 degrees of movement, once again we have half of the pad accelerating in the same direction of the pad and half the pad moving against the rotation.

The Makita has planetary gears that force the pad to spin the same direction as the orbit which creates more revolutions per minute and more movement between the pad and the paint.

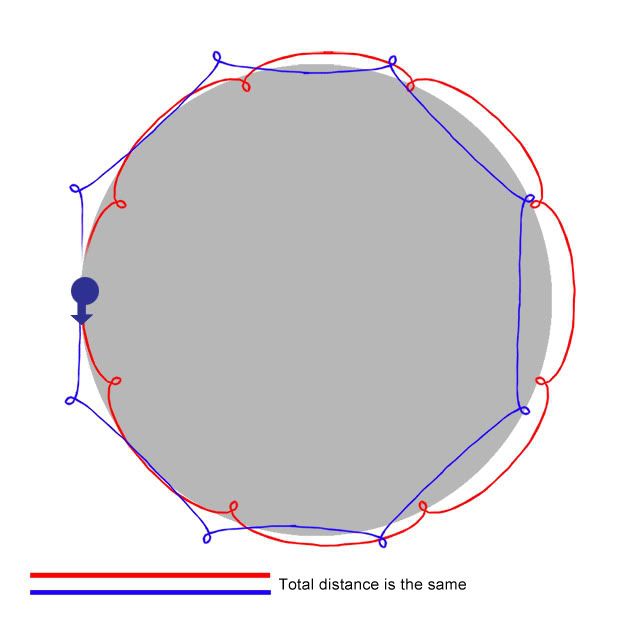

The net effect on the total movement between the paint and the pad is ZERO. If we are measuring the total area the pad is moving (per a given time) across the paint, we will find that machines will similar directions will have more acceleration and de-acceleration in a given orbit, but only slight. The total distance covered will be identical. When the orbit and rotation are heading the same direction (on the outer edge) the pad will accelerate to a spot faster, but then will stall quickly and move backwards slightly, before whipping back out on an arc.

When the movements are opposite, the pad will accelerate more gently, but will slow less, make a less dramatic turn (loop) and resume accelerating smoother. The total distance covered will be identical. It is like driving 45 mph, then slowing to 15 mph, then smoothly accelerating back to 45 mph in a given time frame instead of starting at 50 mph, slowing to 5 mph, and accelerating back up to 50 mph in the same time frame.

My second point, in regards to the Flex vs. the Makita is that the Makita will deliver more RPM and OPM, thus has more cutting ability (potential) if the strokes are identical.

The Flex has a maximum RPM of 480, as verified independently. The Flex will always orbit at 10 orbits per RPM, this is easy to test. Simply spin the backing plate one full rotation and count the amount of times the machine orbits (snakes in and out). A small piece of tape may help. You will always get 10 orbits per RPM, and will a maximum of 480 RPM (verified by a strobe light) you are limited to 4800 OPM max. I am not sure how Flex comes up with a number of 9600 OPM, they must count the inside 180 degrees and the outside 180 degrees of each orbit as separate?

By Flexâs apparent rating the PC/Meguiarâs G110v2 would both have orbit ratings of 13,600 (!) and the Makita 2mode would have rating of 11,600 OPM.

So at least when it comes to the ringside numbers the Makita 2mode has an advantage in both RPM potential (670 vs. 480) and OPM (5800 vs. 4800). When they step into the ring and pressure (thus bog) is applied, I am not sure how they pan out. The Flex is able to maintain near maximum RPM (and OPM) with fairly heavy pressure (as verified by a timer and strobe light). I am unsure about the Makita, but on paper it certainly has higher potential.

-

04-02-2010, 07:21 AM #18

Originally Posted by TH0001

Originally Posted by TH0001

I meant to say this ^ ......................... but I did not have time(or the ability to explain how RO machines work with diagrams that rival quantum physics!!!!!!) me thinks you get a consensus about equipment and then buY it........... or don"t.

I would get my hands on a machine then use it before I posted an opinion on said machine, if a polisher gives you correction to your expectations than that is good enough at the end of the day.

-

04-02-2010, 07:27 AM #19

Originally Posted by TH0001

Originally Posted by TH0001

Your illustrations don`t take into account the way the different machines achieve forced rotation. I`d agree if they both got there the same way, but when the outside edge of the pad is moving with the direction of movement there is more net movement at any give rpm. One direction, with forced rotation achieved by planetary gears adds movement while forced movement by interfacing with the backing plate adds less. Put them side by side and you`ll see exactly what I`m talking about. The outside edge on the flex doesn`t make full circles.

It is interesting to me that the Makita draws less amps but still gets more movement. Also, since I work on a lot of fragile cars, cars with large aluminum panels that can be warped or dented, I try to keep the correction happening by movement between the pad and the paint, not pressure. When, for example, I use my rotary, I sometimes run right up on the edge of the pad but when I do, I have very light pressure. It looks scary but the outcome is fine.

All this being said, I have no doubt other detailers are getting good, even great results using methods and materials different from mine. I`ve seen their work, (Hey Barry, Kevin, Eric etc.) So, for me, what this is about is just letting people know what I`ve figured out and to check my work and to learn from people who`s experience is different from mine.

Robert

-

04-02-2010, 07:40 AM #20

Now this is why I read threads here, great info and civil discussion. Thanks to Todd and Robert! The wife just gave me that, "you ain`t getting another buffer look", sure hate that when it happens, but this time she`s right. We`re going to get an electric power washer today, no, not a cheap POS from the box store, a 400 buck one from Northern Tool. Guess that Makita will be a B-day present.

All I have in this world is my word, and my balls and I don`t break `em for no one, you understand?"

-

04-02-2010, 09:45 AM #21

Wow! I wanted a Festool but now i`m kinda leaning to that makita BO6040

Doing it BIG!

-

04-02-2010, 10:20 AM #22

Originally Posted by JuneBug

Originally Posted by JuneBug

Yeah, +1 :xyxthumbs

While I`m happy with my Flex 3401, I`m finding this discussion quite interesting.

-

04-02-2010, 12:18 PM #23

I like my flex too. I`m just not a fan of the counter clockwise spin. It sometimes is a little tricky

Doing it BIG!

-

04-02-2010, 01:35 PM #24

Originally Posted by WhyteWizard

Originally Posted by WhyteWizard

I agree with you that a similar direction orbit and rotation will produce (by a slight margin) a higher movement speed at the outer edge of the orbit/rotation when they are traveling in the same direction, but this is negated by the fact that on the opposite end (when they are traveling in opposing directions) the pad is moving the slowest.

On a machine such as the Flex, the rotation and oscillation are opposite, the outer edge of the pad will never reach the total speed of the former design, but it also never slows down as much.

As far as their being more net movement, this is not the case. If you take a 5/16th stroke and apply it (in either direction) 10x`s per revolution the distance traveled is identical per RPM. As it relates to the direction of the rotation, the same direction orbit will reach a higher speed (for a few degrees per orbit) but will also walk backwards (away from the orbit) so that the speed is negative. If you plotted a point the same distance out on a fixed orbit da and charted the distance traveled with a string, you would get an identical distance traveled.

As far as putting them side by side, I understand your point and I agree, but you have to remember that an orbit is 360 degrees, so while the same direction will achieve a higher velocity for a few degrees, it also travels much slower (or backwards) on the other side of the orbit.

All this being said, I have no doubt other detailers are getting good, even great results using methods and materials different from mine. I`ve seen their work, (Hey Barry, Kevin, Eric etc.) So, for me, what this is about is just letting people know what I`ve figured out and to check my work and to learn from people who`s experience is different from mine.

Robert

Truer words have never been spoken! :2thumbs:

I have worked with some very high quality, amazingly skilled detailers who achieve awesome results, and each has their own unique methods that work for them. The end result is the goal, but I enjoy the theoretical discussions that have little net effect on overall performance.

-

04-02-2010, 01:43 PM #25

WOW! what a detailing Scientist! Nice Intel! Now I`m really lost! I`ll just stick with my Flex or sell it and get a B06040.

Doing it BIG!

-

04-02-2010, 01:51 PM #26

The main thing the BO6040 has over the Flex is the ability to do DA or just RO at the turn of a button. This feature alone is worth considering if anybody is on the fence. The Makita on-line store has a good deal, around 300 bucks with free shipping and a plastic case. I might have to let the PC or PCXP go and get a Makita, maybe get one and then decide, whatever!

All I have in this world is my word, and my balls and I don`t break `em for no one, you understand?"

-

04-02-2010, 05:37 PM #27

The Makita`s a nice machine. I got one a long time ago and I enjoy it but honestly don`t do much detailing on my family cars anymore (new kid). In any case, when the Makita came out I think the Festool came out shortly afterwards. For some reason everyone sort of latched onto the Festool as the better alternative even though I never really understood why, maybe just because Festool is a very good tool manufacturer and Makita is a little more consumer-oriented. The net of it was that people stopped talking about the Makita altogether and when the Flex came out everyone really only talked about the Festool and the Flex.

-

04-03-2010, 11:13 AM #28

Here are the specs for your comparison:

Flex XC 3401 VRG

Max. polishing pad diameter: 150 mm

Velcro pad: 6 in.

Speed without load:160-480 rpm

Power input: 900 Watts

Power output: 590 Watt

Orbit: 8 mm

Orbit Rate without load:3200-9600 rpm

Weight: 5.75 lbs.

Makita BO6040

Orbits per minute 1,600 - 5,800

No Load OPM 180 - 670

Orbit Diameter 7/32" 5.5563mm

AMPS 6.6

Size(L x W x H) 12-1/2" x 5-7/8" x 5-3/16"

Net Weight (lbs.) 5.9

You can see the Flex has a larger diameter orbit by 1.45mm and

The orbit on the flex accounts for 261888 mm of travel per minute at the center but uses part of that travel to force the rotation, while the orbits on the Makita account for 100166 mm of travel per minute and go in the direction of the rotation which is forced by the use of planetary gears.

The rpss of the Makita accounts for 315570 mm of travel while the rpms of the Flex accounts for 226080 mm of travel.

The Makita loses in number of orbits by 4100, but those orbits go in the direction of the spin, which results in the edge of the pad traveling in a curlicue pattern.

The spin with the Flex is, again achieved by interfacing the pad with the housing and results in the edge of the pad traveling in a scalloped pattern, with the travel coming to a stop at the edge directly in line with the spindle and the housing at when the two are closest.

The Makita creates a lot more movement between the pad and the paint. The proof is in the heat generated when the two are run side by side with pad, pressure, product and paint held constant. The result was/is the Makita by a good margin. The difference is that the two motions orbit and rotation are added together with the Makita but one contributes to the other, rotation drives - therefore subtracts - on the Flex.

I`m going to get a friend of mine to bring his Flex over to the shop and we`ll put a grease pen or something in the pads and run the machines against a surface to show the movement between the pad and the paint and then I`ll post the pictures.

Robert

-

04-03-2010, 08:17 PM #29The orbit on the flex accounts for 261888 mm of travel per minute at the center but uses part of that travel to force the rotation, while the orbits on the Makita account for 100166 mm of travel per minute and go in the direction of the rotation which is forced by the use of planetary gears.

To achieve the numbers you did, I assume you took the throw x pie x maximum OPM. The problem is that the Flex only achieves a maximum unloaded OPM of 4800, not the advertised 9600. This (not pad direction which is irrelevant when we discuss 360 degrees of movement) is likely why you have found the Makita to generate more power.

At a maximum speed of 4800 (10 orbits fixed per 1 revolution at a throw of 7.9375 mm) (7.9375 x 3.14 x 4800) would move a point on the pad about 119,634 mm per minute on the Flex.

At a maximum speed of 5800 (8.66 orbits fixed per 1 revolution at a throw of 5.563 mm) (5.5563 x 3.14 x 5800) would move a point on the pad about 101,191 mm per minute on the Makita.

At this point the Flex is producing more orbital movement in a given minute with out accounting for the additional movement provided by the rotation of the pad. The Makita produces only 84 as much movement.

The rpss of the Makita accounts for 315570 mm of travel while the rpms of the Flex accounts for 226080 mm of travel.

I am not sure how you achieve these numbers, as calculating the distance covered by the revolution requires knowing the distance covered during each revolution, which is dependant on pad size.

With out accounting for RPMâs, the Flex is in the lead. However the Makita has almost 40% more RPM, which gives the Makita more total movement by about 24% for a given time.

(40%-16%).

The Makita loses in number of orbits by 4100, but those orbits go in the direction of the spin, which results in the edge of the pad traveling in a curlicue pattern.

The direction of a 360 orbit has nothing to do with it. The Makita, by virtue of spinning faster (670 RPM vs. 480 RPM) moves the pad further on the paint per minute, even though it doesnât move it as far per rotation.

At the edge of both machines produce a similar but inverse pattern.

The spin with the Flex is, again achieved by interfacing the pad with the housing and results in the edge of the pad traveling in a scalloped pattern, with the travel coming to a stop at the edge directly in line with the spindle and the housing at when the two are closest.

Correct. But it makes no difference because the total distance traveled is identical as illustrated in my rather terrible (scale) diagram below.

The Makita creates a lot more movement between the pad and the paint.

Yes it creates more movement at maximum RPM because it spins faster.

The proof is in the heat generated when the two are run side by side with pad, pressure, product and paint held constant. The result was/is the Makita by a good margin.

Bog aside (assuming both machines are able to overcome the friction between the pad and paint) the Makita should generate roughly 24% more corrective potential at full speed.

The difference is that the two motions orbit and rotation are added together with the Makita but one contributes to the other, rotation drives - therefore subtracts - on the Flex.

Because an orbit is 360 degrees both directions spend an equal time moving against the padâs rotation and with the padâs rotation.

I do agree that the drive system on the Flex takes more power to operate then the efficient planetary gears on the Makita (not to mention centripetal force will actual want to spin the pad in the same direction as the orbit) but much like race car, the amount of power used to drive the movement doesnât matter, the amount of power that reaches the rear wheels does.

The Flex is a very hard machine to bog, even with an inefficient drive system, because it is so powerful. Itâs like horsepower measured at the wheel, if you have enough to hit redline in top gear, more will not make you faster.

I would assume that the Makita (because of itâs more efficient direction that works with centrifugal force and gearing) is pretty bog resistant as well, although likely not as much as the Flex.

I love discussions such as this and appreciate anybody who takes the amount of time to think of such *trivial* things like I do. Open discussion, when kept respectful, and with a common goal (education) is great for everybody. Thanks Robert!

-

04-03-2010, 08:42 PM #30

Festool 6" Sander ETS150/5

Is this the model? There is one on CL for 239 with low hours and I need this or the Flex.

Thanks for those that know, Rob

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

FesTool VS. Flex

By Coug in forum Machine Polishing & SandingReplies: 3Last Post: 01-16-2012, 12:06 AM -

Festool RO 150 FEQ Rotex or Flex 3401

By DM101 in forum Car Detailing Product DiscussionReplies: 1Last Post: 05-04-2010, 10:58 AM -

Flex review & Video comparing the Flex XC 3401/Porter Cable 7424

By blkyukon in forum Paint Correction and Gloss EnhancementReplies: 25Last Post: 03-06-2008, 11:39 AM -

Festool RO 150 FEQ and Flex XC 3401 VRG Pictures Thread

By ZoranC in forum Car DetailingReplies: 27Last Post: 12-31-2007, 06:23 PM -

Whats the better Machine Flex Flex Tool XC 3401 VR OR Cyclo Polisher?

By LanceM in forum Machine Polishing & SandingReplies: 13Last Post: 12-16-2007, 07:11 PM

Reply With Quote

Reply With Quote

Bookmarks