This is a black Honda Civic Hood. Can you finish this panel in 4 passes?

A few days ago, while being really frustrated with the holograms on a black Camry,

I discovered something I will refer to as âOrion Chang Method â

Kevin Brown Method(KBM) has been around pretty much all the detailing forums.

From my understanding it uses the DA to its full potential with just 1 polish and 1 pad.

KBM seems to be able to cut hard, yet finish down nearly perfect. It takes a bit of patience,

and takes a toll on the pad.

My method focuses on the rotary. Starting with #2000 sanding marks,

itâs able to reach perfect finish in 4 passes.

Tools needed:

Iâve done a lot of tests, LC red and Menzerna 83Q works best in this case.

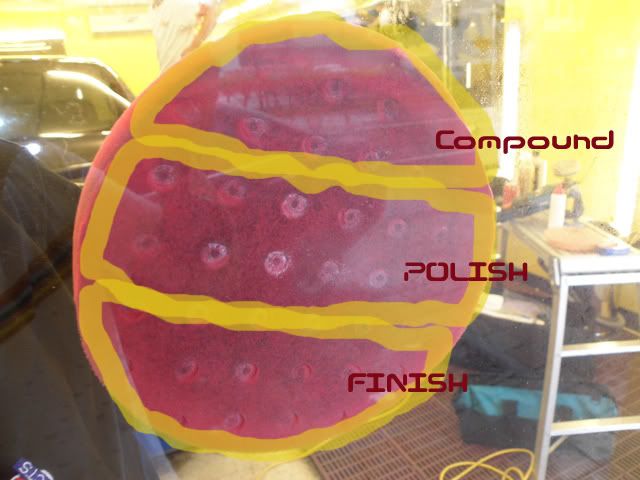

The following 2 pictures show the mechanics of the method.

The pressure is focused only on the left side, while lifting the right side enough for

the pad to be barely gliding on the paint. You would always move towards the pressure side,

so the lifted side will finish down smoother. With any luck, compounding, polishing, finishing

will be done with the same pad and polish.

Like in a CNC machining environment, you donât cut back and forth. If you do cut back and forth,

finish would become very rough. So we imitate the same process with our polisher.

The traditional method puts the pad flat on the surface, despite the possible curves on the panels.

This usually makes us put slightly more weight on the side weâre moving away from so we can handle

the machine movement better. This has a higher tendency of leaving swirls/holograms that is equal

or deeper than the polish/pad combination.

What Iâm doing is reversing the mechanics - Having more pressure on the initial cut, and finishing

down as youâre moving away.

Some pictorials:

You only need a about 4 drops of 83Q evenly spread throughout the radius of the pad, any more it splatters.

Speed 1 to spread the polish.

Polish at 800rpm.

Short video clip of the method

YouTube - OCM

This picture shows the difference in the density of the contact â strong on one side, weak on the other. This shows the difference in the cutting strength.

This is the result

Do note that the surface temperature rises VERY quickly.

Working OCM on actual car

The finish looks awesome!

After doing 2/3 of the car, the pad is unharmed.

Results 1 to 12 of 12

-

08-11-2009, 05:23 AM #1

-

08-11-2009, 07:53 AM #2

Please remove the URL from your watermark.

Thanks,

Tort

(moderator)

-

08-12-2009, 12:47 AM #3

Originally Posted by TortoiseAWD

Originally Posted by TortoiseAWD

Sorry, already edited...

-

08-12-2009, 01:34 AM #4

nice now did you use same product on the whole pad? is the concept just using one product but with one side tilted more than the other to simulate the tough cutting to light polishing to finishing? i`m assuming that`s how the concept is explained i`ll give it a try this weekend when i polish out a camry as well, Thanks!:dance

-

08-12-2009, 05:02 AM #5

Have you ever wiped the "after" finish down with alcohol, pulled it in the sun for a while and inspected for defect return?

Metro Detroit`s leader in cleaning, preserving & perfecting fine automobiles!

-

08-12-2009, 05:25 AM #6

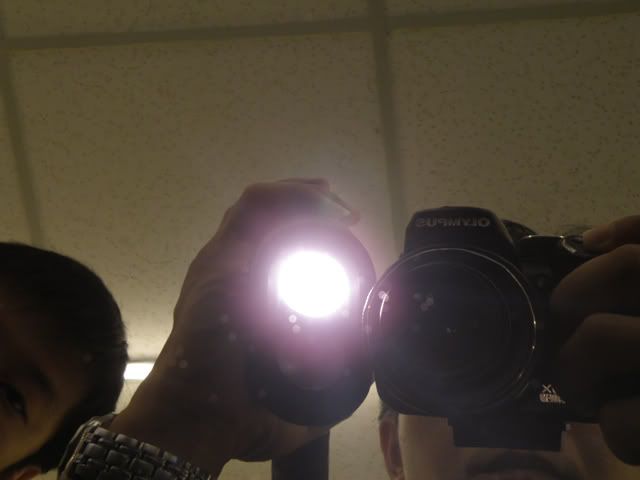

Not to sound like an *** here. I think what your doing is great, but your gonna have your thoughts questioned here. first off your first couple of pictures your using a camera flash. Then you you show a picture of you doing this with a 20$ brinkman light. Those brink man lights are not a substitute for a camera flash or a sun gun. I have all I know this. Now your combination can remove 2000 grit paper marks in 4 passes. I could have done it in one wool pad and finished down just as nice as your first few pics if not better. My next ? is if your applying pressure at that one spot on the pad the whole time. this will create holograms. Its uneven pressure. I`ll bet if you put your camera flash up to that same spot where your brink halogen is you will see this. Good luck on your adventure. TO sum up why the Kevin Brown Method works is because your using a non diminishing polish that the abrasives don`t break down. Maybe I should come up with the Barry Theal Method Leveling paint with paper? Good Luck Mr Chang on your adventures.

Barry E. Theal

Presidential Details Of Lancaster PA

Founder of Americana Global Inc.

-

08-12-2009, 05:40 AM #7

Also, it appears that you are saying to combine a polish and compound on the same pad at the same time. How do you know that when it is time to re-apply, you are applying the same product to the same part of the pad...do you write "polish" and "compound" on the pad. Also, I have to agree with Barry on this one, also, that applying pressure to only one section of the pad would create holograms. The "steeper" the angle on a rotary pad, the more holograms you will get. Just a few thoughs....

Ryan Cywinski - Owner

Northeast Auto Reflections

Detail Spa and Mobile Wash, LLC

www.northeastautoreflections.com

-

08-12-2009, 06:31 AM #8

Originally Posted by Street5927

Originally Posted by Street5927

He`s not combining multiple products on the same pad but using just one polish & pad while trying to do the work of three by using varying pressure on different parts of the pad.

To me all he is doing is polishing. You can`t compound with a medium polish, nor can you finish well with a medium polish. If you are using one product to do multiple jobs like this then you limited to the polishes ability, regardless of pad choice, rpm, pressure, etc.

-

08-12-2009, 11:38 AM #9

Originally Posted by bufferbarry

Originally Posted by bufferbarry

Heh heh, bufferbarry took the words right out of my mouth, including his hope that he doesn`t sound like a [jerk].

I`ll even go so far as to say that the SunGun doesn`t always show everything, at least IME.

Anyhow, Welcome to Autopia, orion613719! That`s some good food-for-thought you posted there.

Maybe I should come up with the Barry Theal Method Leveling paint with paper?

Heh heh, with some of the stuff *you* pull off you *oughta* have some method named for you

-

08-12-2009, 12:10 PM #10

I had this long post written up but somehow hit refresh so it erased everything.

I`m just going to get to the point.

Since your using a diminishing abrasive, won`t the side with no pressure have more "cut" than the side with pressure since the side with pressure will have broken down long before the side without pressure?

This might work decently, in theory, with the pc/m205/red pad.

-

08-12-2009, 12:34 PM #11

Originally Posted by Dsoto87

Originally Posted by Dsoto87

It`s the same section of the pad that`s under pressure and not under pressure....

So I think the answer to your question is no.

If the polish broken down on the pressured side its` still going to be broken down on the unpressured side when the pad turns 180deg.

I don`t have a PC but I know it`s a random orbital (not forced DA) so I`d assume putting this much pressure on a PC (at an angle mind you) would keep it from rotating properly (which defeats the whole purpose of this method). Best take that statement with a grain of salt though as just a theory on my part. Perhaps the PC owners can chime in.

As far as the OP: I think any "method" needs to be tested in a variety of enviornments before it can be considered a "method". This data sample is way too small to say this works or doesn`t work. Soft clears, hard clears, in between clears? What about single stage paint?Abralon Surfaced-Makita Powered-Club Flex Finished

-

08-12-2009, 12:46 PM #12

Your right I didn`t think that through enough. Hey, I`m running off 3 hours of sleep, what can I say

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

1960 Chevrolet Biscayne 2 step polish protected with Mothers Carnauba Finishing wax

By MR Prime Shine in forum The Detailers ShowcaseReplies: 7Last Post: 05-13-2014, 07:29 AM -

Issues with soft paint and finishing polish on a rotary

By smbstyle in forum Machine Polishing & SandingReplies: 2Last Post: 05-24-2013, 10:31 AM -

Finishing step..

By solekeeper in forum Machine Polishing & SandingReplies: 6Last Post: 06-01-2012, 07:05 PM -

Finishing polish for use with rotary

By ron231 in forum Car DetailingReplies: 7Last Post: 06-08-2007, 01:12 AM -

Rotary vs. PC for Finishing Polish

By imported_Dave KG in forum Machine Polishing & SandingReplies: 39Last Post: 09-12-2006, 08:29 PM

Reply With Quote

Reply With Quote

Bookmarks