In reading about the Kevin Brown Process, I have come up with a basic understanding, but am still waiting for the final document to be released.

I believe the idea is to turn the foam pad into a sheet of variable grit sandpaper. Non-diminishing grit is housed in the pad, then via pressure it is extruded though the pad on to the surface.

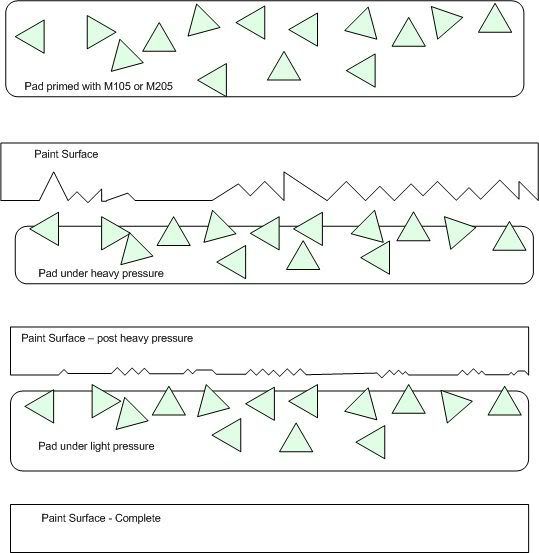

Am I correct in my representation below?

A. Pad Primed with media

B. Surface shown with major defects

C. High pressure is applied to the pad, thus extruding abrasives and removing deeper defects

D. Pressure is gradually releived, thus reducing the amount of abrasive protruding hence polishing a finer level of defects

E. FINISHED

Is the idea of spraying water onto the surface to induce capilary action to draw more abrasives to the surface of the pad for more cut?

Seems we have gone full circle with polishing processes. This takes me back to the days of sanding primer with a "mudder" which could carefully remove mass amounts of material quickly in professional hands.

Results 1 to 15 of 260

-

03-11-2009, 07:34 AM #1Detailing Technology - specialista vernice di correzione

-

03-11-2009, 07:49 AM #2

Why not just use a polish with diminishing abrasives?

-

03-11-2009, 07:52 AM #3

Originally Posted by Danase

Originally Posted by Danase

I think the idea with the KBM is that it allows for very rapid correction while finishing to a reasonable level, all in one step (and being faster than rotary).

-

03-11-2009, 07:53 AM #4

Originally Posted by Setec Astronomy

Originally Posted by Setec Astronomy

But don`t you waste a ton of product that way? Maybe I`m lost.

-

03-11-2009, 07:56 AM #5

Bob - I`m just GUESSING on the process from reading the posts here.

To me if it works like a charm, Im happy to burn through a 32oz bottle of polish or a Porter Cable every month. Its just the cost of learning / doing business. We`ll just hunt for better tools.Detailing Technology - specialista vernice di correzione

-

03-11-2009, 07:58 AM #6

I don`t fully understand this either. 1 this has been around for quite a few years. (ever since I`ve seen foam pads used) I really kind of thought this was detailing 101 here. and 2. I agree with Bob it really does waste a lot of product in effort to save a little bit of time.

-

03-11-2009, 08:02 AM #7

Add to this, all the recent posts abount Menzerna polishes. I am tempted to call back all of the work I did this year to review. If I see the magical return of swirls, etc becuase the product is somehow immune to a few passes with an IPA wipedown, Im changing my process.

Not going to be the most cost effective, but a least I`ll know I am providing an honest service.Detailing Technology - specialista vernice di correzione

-

03-11-2009, 08:07 AM #8

Originally Posted by Jakerooni

Originally Posted by Jakerooni

That`s what I was thinking. I thought it was standard thinking that if you press harder you are going to get more cut.

Maybe I`m just not getting it or maybe it`s new to some?

-

03-11-2009, 08:07 AM #9

I think its a good idea to publish the process as a great majority of people have been putting a few pea sized drops of polish on the surface of foam pads, then working it into the paint.

Seems like a whole new mindset to follow this process.Detailing Technology - specialista vernice di correzione

-

03-11-2009, 08:08 AM #10

Yea there just has to be something to this I`m not understanding fully. Everyone seems to be hailing it as some sort of detailing breakthrough but if it`s what I`m thinking most have been using this as they learn how to do the basics of paint correction for years. So I have to be missing something here.

-

03-11-2009, 08:12 AM #11

My understanding is minimal. I havent witnessed it or tried it yet. It seems to remind me of the old 8" D/A days sanding filler primer in the body shop. Might be me just reflecting back to those days, I dont know.

I love when things make a full circle like this. Just shows such a victory.Detailing Technology - specialista vernice di correzione

-

03-11-2009, 08:14 AM #12

I think it goes back to TH0001`s thread showing that a PC actually can remove more paint than a rotary (I forget the details). The use of a PC and a non diminishing abrasive cuts faster with still no (minimal?) chance of burning, as compared to wool or foam cutting pad on a rotary. That`s what I`m getting from it, since the guys doing it are hardcore rotary users using it on brutalized paint.

-

03-11-2009, 08:20 AM #13

Originally Posted by Setec Astronomy

Originally Posted by Setec Astronomy

100% agree with Todd on that. Its back to the old school.

We used an 8" "Mudder" D/A when we had to sand filler primer from a butchered panel, or fix someone elses butcher body job, down to bare metal. We didnt use a grinder.Detailing Technology - specialista vernice di correzione

-

03-11-2009, 08:28 AM #14

mmmm??? I`m going to hold my tounge until this is fully explained. But if it`s my understanding on how this works I`ll gladly tell you an even easier way that uses much less product that gives you the same results... (I`d call it detailing 102 LOL) But because I seriosuly think I`m just missing something here I`ll wait until it`s explained a bit better.

-

03-11-2009, 08:36 AM #15

We can look back on this post once the process is unveiled.

I`m going to give what I interpret the process to be a go this weekend on a beat up Infiniti.Detailing Technology - specialista vernice di correzione

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Kevin Brown Method

By albe in forum Car DetailingReplies: 3Last Post: 03-27-2010, 10:00 PM -

Kevin Brown Method - What pad?

By ISLover in forum Machine Polishing & SandingReplies: 8Last Post: 10-22-2009, 03:47 AM -

Kevin Brown Method???

By ISLover in forum Machine Polishing & SandingReplies: 15Last Post: 08-27-2009, 07:13 AM -

Kevin Brown Method

By TonyTahoe in forum Polishing with a DA PolisherReplies: 9Last Post: 03-30-2009, 10:53 AM -

Kevin Brown`s Method

By Claude in forum Machine Polishing & SandingReplies: 13Last Post: 03-30-2009, 10:52 AM

Reply With Quote

Reply With Quote

Bookmarks