Last week, in a discussion with some detailers, I theroized that the portercarble removes more paint then a rotary. My reason was simple, the rotary levels paint better and flatter, where as the isolating action of the DA could "chase the scratches" more.

So I picked up the hood of a wrecked 99 Toyato Tacoma two days ago from a local bodyshop and set to work. Unfortunately, my camera is down (in the shop for sensor cleaning) so I couldn`t take pictures, but I will redo this test with pictures in the near future.

The hood was black and had moderate to light swirling (and hologramming) but a lot of rids in straight lines. Perfect for the test, IMO.

I taped the hood into the thirds, then using thin tape, divided each third into the thirds (so I had a tic-tac-toe board). By marking and using a straight edge, I was able to accurately measure the same exact spots to ensure accurate paint differences.

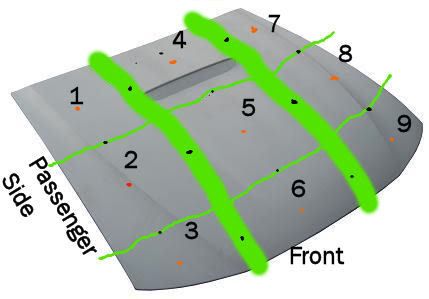

Here is a picture showing what I did.

The hood was orginally taped front to back to split it in the sections. The passenger side was to get wetsanding then polished to perfection. The middle section was to get polished only with a rotary to perfection. And the driverside was to get only the DA until perfection.

To make measuring the paint more accurate, I divided the box horziontally (thin green lines) and marked the tape using black marker (black dots on green lines). This allowed me to use a straightedge to measure the same area each time (orangish dots).

I also numbered the panels vertically, with sections 1-3 getting wetsanded, 4-6 getting machined with a rotary, and 7-9 using the portercable.

First up was the DA only side. To keep this test fair, I elected to use commonly (and similar products) for all three sides. Since Menzerna SIP and 106ff have such a following by both rotary and PC users, I decieded on these two for the work. I also included PowerGloss Compound for rotary use, since one of the benefits of the rotary is the ability to level paint quicker.

On the DA, I used a 6 inch Lake Country Orange CCS pad for the "cutting" and a couple drops of Menzerna SIP. I polished using slow arm speed and long overlapping passes in both left-right-left and up-down-up motions until the polish began to clear and flash. This process took about 3 minutes to fully break the polish down per application.

After one application, I wiped clean (I kept 91 percent alcohol and fresh microfibers near by for quick removal of product). There was a nice reduction in the swirls and holograms, though some deeper swirls remained, as well as moderate rids.

Time for another application...

and another...

and another...

Finally after polishing each section driver side hood 5 times, I had removed all swirls, but still had some straight line rids. So I continued on...

For 3 more passes, until all defects where removed and the paint was perfect. To do the entire passenger side of the hood to this point had taken slightly over an hour. Next I followed with 106ff to remove any micromarring on speed 5 and a Lake Country White CCS 6 inch pad.

The paint looked great.

Next up was the center section, with rotary only. Because one of the advantages of the rotary is the ability to use more aggressive methods, I did keep a Lake Country Yellow Pad and Menenzerna PowerGloss on hand. But to keep the test fair, I wanted to start with SIP and an orange pad (same as Porter Cable).

I worked the SIP by staring at 1000 rpm, then jumping up to 1700 before cascading back down to 1000 rpm. It took about 40 seconds per application. One pass reduced all the haze and swirl in the paint, but still left the rids, which looked untouched. I decieded to step up to PowerGloss and the Yellow Pad. I kept the RPM at 1500 and worked the PowerGloss until clear, about 20 seconds each application.

After one application in the center of the hood, I wiped clean with alochol. 90 percent of the rids where gone, but there was moderate hologramming from the yellow pad and compound. I required one more pass of PowerGloss (at 1200 rpm and worked slightly longer) for complete removal. I followed with with Menzerna SIP and an orange pad which made the paint perfect. I finished with 106ff on a blue pad.

Now 2/3rds of the paint where perfect. Where as the DA side took an hour to get perfect (and 8 application of SIP/1 of 106ff), the rotary side moved quickly 15 minutes (2 applications of PG and Yellow, 1 application of SIP and Orange, 1 application of 106ff and blue).

Now for the wesanding. I used Meguiars Unigrit sandpaper (3000 grit) for the defect removal. I started by soaking the paper in a bucket with a couple drops of dawn for 15 minutes, then wrapped the paper around a soft flexiable Meguiars sanding block. Car was used to remove just enough paint to level the rids.

I would make three or four passes with the 3000 grit in one direction then wipe clean and dry and inspect. The paint was gray, but the rids where still visible. This was followed by three to four more passes and reinspected until all visible RIDS where removed.

After 3000 grit (it took only 5-8 "passes" to remove all rids) the paint had a nice, level satin finish.

Now it was time to polish the paint. 3000 grit wet leaves an incrediably nice finish, the doesn`t always require a compound to cut it so I started with SIP and an Orange pad worked at 1700 rpm. It restored full gloss to the paint very quickly, and showed no sanding marks that would need to be cut. I finished with one application of 106ff on a blue pad to ensure paint perfection.

So now the hood had been made perfect by all three standards, and to my eyes looked perfect.

So what was my final verdict?

Here are the measured paint levels before and after and my conclusion.

Up first, sections 1-3, the wetsanded side.

Before After Reduction

1. 3.8mil 3.8mil .0mil

2. 4.1mil 4.0mil .1mil

3. 4.0mil 3.9mil .1mil

11.9mil 11.7.m .2mil

So the wetsanded and polished side showed a total of average of .67mil reduction or a total of .2mils for three sections.

Second, section 4-6, the rotary side. Compounded, polished, finished.

Before After Reduction

4. 4.1mil 4.0mil .1mil

5. 4.2mil 4.0mil .2mil

6 4.2mil 4.1mil .1mil

12.5mil 12.1mil .4mil

The rotary side showed an average of .13 mil reduction or a total of .4 mils over 3 sections.

Lastly the PC

Before After Reduction

7. 3.8mil 3.6mil .2mil

8. 4.3mil 4.2mil .1mil

9. 4.2mil 4.0mil .2mil

12.3mil 11.8mil .5mil

The PC side showed the most reduction at .167mil reduction average or .5 mils in three sections.

An intresting conclusion, but it no ways meant to be an end all, be all. I thought the conclusion was pretty cool, so I thought I would share.

Results 76 to 89 of 89

Threaded View

-

04-01-2008, 11:44 AM #1

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Claying removes paint??

By cmk-2 in forum Washing, Drying, and ClayingReplies: 3Last Post: 05-27-2014, 07:08 AM -

Detailing/rotary questions...you pick the ones to answer!

By useth4z in forum Car DetailingReplies: 7Last Post: 04-02-2007, 03:53 AM -

Which Process Removes the Most Paint?

By Mikeman in forum Car DetailingReplies: 5Last Post: 12-13-2005, 07:13 PM -

Is a rotary necessary after wetsanding?

By NorcalZ71 in forum Car DetailingReplies: 5Last Post: 08-05-2004, 06:00 PM -

Wetsanding vs. Rotary vs. PC, what removes more paint? (The answer may shock you)

By in forum Car DetailingReplies: 0Last Post: 01-01-1970, 12:00 AM

Reply With Quote

Reply With Quote

Bookmarks