Originally Posted by evilWagon

Any way that gets you the results your looking for is the way to go! As Todd stated, its just an observation test, as there are many variables that could be challenged here. Awesome test...makes you think if you have a heavily scracthed/swirled car, wetsanding may be the way to go!

I have questions, but im trying to figure out how to ask them...:think:

Results 16 to 30 of 89

-

04-01-2008, 05:20 PM #16Garrett Hess

Top2Bottom Auto Detailing--"Your Recondition Specialists"

Top2Bottom Auto Detailing--"Your Recondition Specialists"

-

04-01-2008, 05:46 PM #17

To answer the questions (and please understand I am only logically guessing)....

Lets assume the RIDS on this hood where all .02 of a mil deep (and this is one of the variables of this "test" that could be challenged).

To get the paint perfect, we need to remove .021 of a mil to reach flat, level paint, then refine the finish with a final polishg which may remove another .001 mil. So for perfection, we need to remove .022 of a mil.

I believe by wetsanding cautiously and constantly checking, it is possible to remove just enough paint for perfection.

By rotary, you are able to approximate the removal.

By PC, you are simply guessing by making passes under a lot of pressure until the polish is broken down.

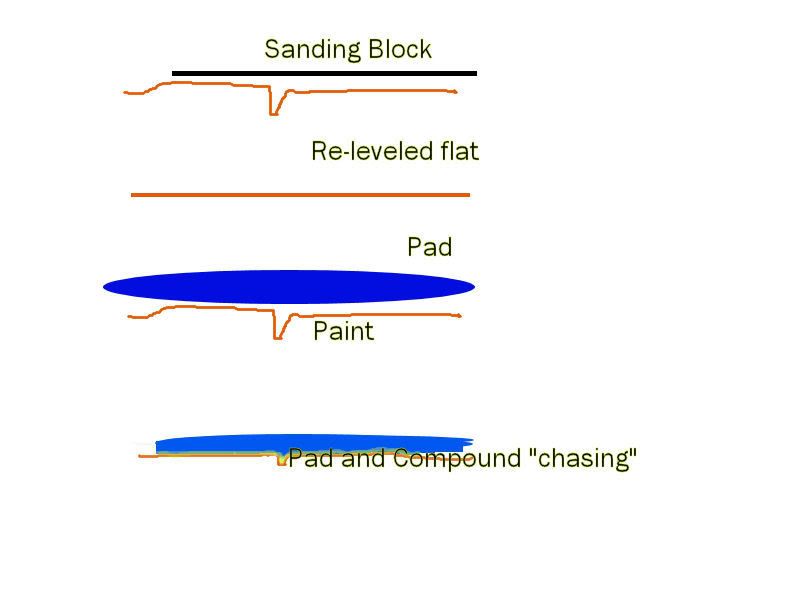

I think as far as chasing scratches down, the simplest way to think about it is like orange peel (which is microscopic highs and lows in the paint). You cannot polish away orange people, because the pad will contour to the highs and lows of the paint.

As you polish away scratches using a DA (and to a lesser degree the rotary) you are working the polish and contouring the pad into the scratch (especially the depth of the scratch reduces) which will remove some paint from the lows of the scratch itself. So ineffect you are removing paint from outside as well as inside the scratch. As it becomes less and less, you begin to remove more and more paint from the scratch until you get it level.

With a rotary and compound, you can quickly level the paint and remove scratches with minimal "chasing". With a portercable, you are going to push the depth of the scratch down more.

-

04-01-2008, 05:57 PM #18

Very very interesting results, can never expect less from you haha. Should be interesting discussion and testing material for sure.

:xyxthumbs

-

04-01-2008, 05:58 PM #19

The orange lines represent the paint and the "v" being the scratch at high zoom cross section.

I think this illustrates why sanding is more precise.

-

04-01-2008, 06:53 PM #20

Originally Posted by TH0001

Originally Posted by TH0001

Hmmm.....

I`m thinking April fools on this diagram......

Maybe the whole show........

-

04-01-2008, 07:23 PM #21

Originally Posted by Dave1

Originally Posted by Dave1

I`m not sure why you think that. If you have to remove a certain amount of paint to reduce defects, wouldn`t it make sense to do it the most precise way possible?

The diagram is crude (at best) but I only did to show what I believe is happening (at a microscopic level).

-

04-01-2008, 08:01 PM #22

Originally Posted by TH0001

Originally Posted by TH0001

It`s the "chasing scratch theory" that has me thinking on this 1st day of April......

My wife has already tried today. She called and explained in detail about the guy who rear-ended her on the way home from work.......Had I not been used to these performances, I would have been sick.....

Anyway.....what is the volume of pressure exerted on the floor of the scratch from the applied force from above.....?

Does a compound exert more pressure than sanding residue inside the same framework....?

Do pad selections and their firmness absorb the hydraulic properties of the scratch chase contention.....?

I don`t know.......I`m just pondering these new destructive clear coat forces the PC now seems to be accused of........

-

04-01-2008, 08:08 PM #23

Geez... I wish I had the skill to wetsand and use a rotary so I understand better.

Converted over to ONR & now Lowes grout sponge. Protected by 3M clear bra, and one layer of Zaino is all you need!

-

04-01-2008, 08:39 PM #24

Originally Posted by Dave1

Originally Posted by Dave1

My wife has already tried today. She called and explained in detail about the guy who rear-ended her on the way home from work.......Had I not been used to these performances, I would have been sick.....

No joke, sorry...

Anyway.....what is the volume of pressure exerted on the floor of the scratch from the applied force from above.....?

No idea, its just a theroy.

Does a compound exert more pressure than sanding residue inside the same framework....?

I would imagine that the pressure exerted by pressing a pad and compound down would be far greater then the gliding the of the flat surface. I would imagine it is almost zero to none.

Do pad selections and their firmness absorb the hydraulic properties of the scratch chase contention.....?

I would imagine that a softer pad would do more chasing, though this would probably occur less on a rotary since the you are planeing the surface.

I don`t know.......I`m just pondering these new destructive clear coat forces the PC now seems to be accused of........

There is no desctructive force. If you need to remove paint, you need to remove paint. If you have to remove .02 mils, the only question is which process gives you the ability to remove .02 mils the most precisely.

If you don`t believe that pads and compounds "chase" perhaps you would explain to me why you can`t buff away orange peel?

Most RIDS and swirls we see are microscopic in depth, and this needs to be kept in prespective. As the paint around the microscopic scratch is removed, there is going to be contact between the depth of the scratch and the pad. I`ve heard body men discussing chasing scratchs for a long time, so I am suprised this is the part of my theory that is even questioned.

-

04-01-2008, 08:40 PM #25

Originally Posted by Macruz19

Originally Posted by Macruz19

Come on down to Orlando and I`ll show you how to do both.

I will also do what I did with Pats300ZX (the moderator) and prove to you that SIP and 106ff fill (ask Pat).

-

04-01-2008, 09:05 PM #26

Originally Posted by TH0001

Originally Posted by TH0001

This is true.....

Anything that has some cut will in esscence fill the left over inclusions on the surface with residue from the work performed......

A rinse or "flush" is required to remove any residue left inside the inclusions. Certain cleaning agents may require a dwell time after a flush for the product to flash or dry before a another product is applied. A heat lamp will accelerate dwell times when necessary for certain applications......

-

04-01-2008, 09:09 PM #27

I was also thinking about this. I used some 3m3000RC by my Ridgid and orange pad to remove some sanding scratches It did a remarkable job but left a slightly hazed surface so I had to 3 step it. On another section i tried the same 3m compound by rotary with a german green pad and it left a better surface so I was able to go direct to my finishing polish. My theory is that the hard Aluminum Oxide abrasives break down much faster by rotary. With a RO they perform more of a sanding action as they break down. That is why IMO the PC can remove more clear than a rotary with heavy duty compounds.

-

04-01-2008, 09:52 PM #28

I have to agree with Todd on the D/A vs. Rotary in chasing. Since the rotary works much faster than a D/A at correction, you are able to flatten the surface in a shorter amount of time, thus preventing the pad from dipping down into the crevice (persay) of the scratch and thus "chasing" the scratch further and further into the surface. Its crude logic, but it does make sense. (to me at least.) I dunno, maybe im wrong.

-

04-01-2008, 10:20 PM #29

Originally Posted by wannafbody

Originally Posted by wannafbody

Hmmm....

Ok, so your RO was sanding and your rotary was cutting.......(basically from your post)

Did the sanding action remove more cc than the cutting action....? (pads were different, so it`s hard to tell here IMO)

Two steps are nice but, is it possible that the first rotary step removed more scratches from the surface than the RO did....?

Heavy compounds with a rotary can do some serious paint damage in a hurry if your not careful. Heavy compounds with a RO will not do as much damage as quickly using the exact same products .....IMO

-

04-01-2008, 10:27 PM #30

Very interesting test. I agree with your theory that wetsanding gives you greater control so you stop the instant the RIDs are gone.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Claying removes paint??

By cmk-2 in forum Washing, Drying, and ClayingReplies: 3Last Post: 05-27-2014, 07:08 AM -

Detailing/rotary questions...you pick the ones to answer!

By useth4z in forum Car DetailingReplies: 7Last Post: 04-02-2007, 03:53 AM -

Which Process Removes the Most Paint?

By Mikeman in forum Car DetailingReplies: 5Last Post: 12-13-2005, 07:13 PM -

Is a rotary necessary after wetsanding?

By NorcalZ71 in forum Car DetailingReplies: 5Last Post: 08-05-2004, 06:00 PM -

Wetsanding vs. Rotary vs. PC, what removes more paint? (The answer may shock you)

By in forum Car DetailingReplies: 0Last Post: 01-01-1970, 12:00 AM

Reply With Quote

Reply With Quote

Bookmarks