Prelude:

Meguiar`s changed the detailing industry with the introduction of Meguiar`s M105 Ultra Cut Compound several years ago. Until this point, traditional rubbing/polishing compounds used a coarse "diminishing" abrasive that would leave noticble swirl marks and haze when worked against the paint. This often required an additional two steps of polishing to achieve a flawless finish.

Meguiar`s utilized a new type of non-diminishing aluminum oxide abrasive which still delivered a powerful cutting action but left a finish that was as good as most medium grade polishes. Meguiar`s choose to market this type of abrasive as SMAT, or Super Micro Abrasive Technology.

Many products have come to market in the last few years attempting out perform M105, and while some exceptional performing compounds are now available, nothing has definitively beaten Meguiar`s flagship compound.

Menzerna GmbH is a polishing compound manufacturer from Germany whose polishes utilize some of the most technologically advanced aluminum oxide abrasives. Their polishing range has gained critical acclaim and widespread respect from detailers, enthusiasts, and even other manufacturers. Menzerna FG400 is their official entry into the heavy-cut, high-gloss finishing compound market.

If you are interested in the results, skip to post #2, which will focus solely on the testing and the specific results encountered. The result of post #1 is going to highlight the differences in each polish, abrasive theory, and may help explain why each product behaved differently in different situations. I feel that this level of knowledge, inherent to AutopiaForums, is necessary for those who are looking to achieve maximum results from products.

Aluminum Oxide As An Abrasive:

Both Meguiar`s M105 Ultra Cut Compound and Menzerna FG400 use aluminum oxide powder (Al2O3) as their primary abrasive material. Aluminum oxide makes an excellent abrasive medium in paint polishes because it can be engineered in various sizes, shapes, and levels of sharpness to alter the characteristics of the polish. Aluminum oxide is also extremely hard. On the Mohs Scale of Hardness it is rated as a 9. Diamonds, for example, are rated as a 10.

Because aluminum oxide is so hard (particular compared to automotive paint finishes, plastics, and even glass) it really does not break down. Even after repeated friction the abrasive retains much of its initial behavior/polishing action. This means that some level, whether or not it is classified as such, all aluminum oxide is non-diminishing (in context of paint abrasion).

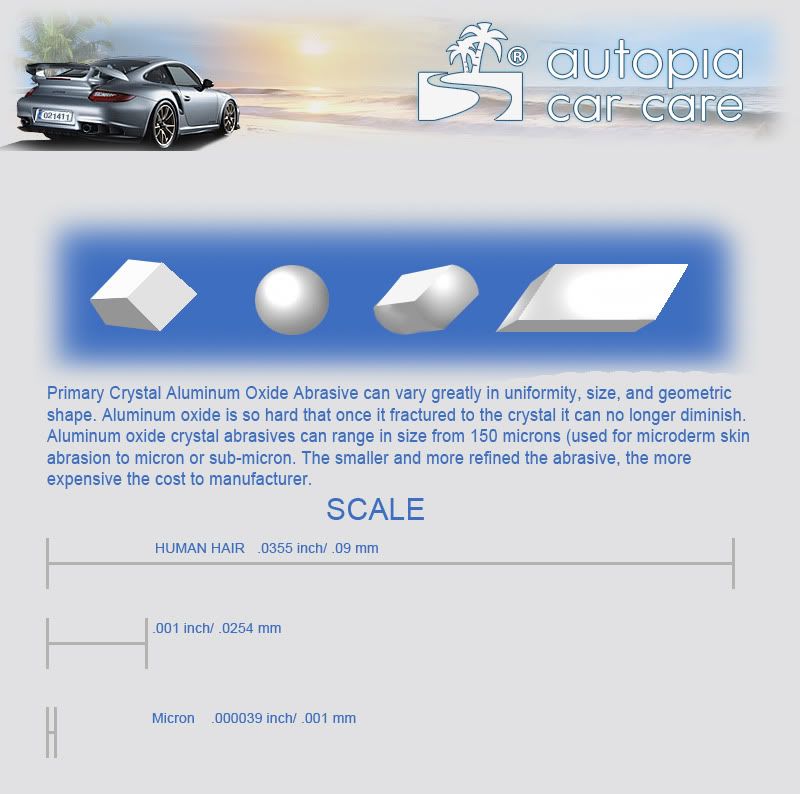

It all starts with the (primary) crystal. This is the smallest, most refined abrasive. As depicted in the picture below, aluminum oxide abrasives come in a variety of shapes, sizes, and levels of sharpness. Modern technology has allowed this crystal to become more refined, more uniform, more consistent (abrasive to abrasive) and smaller. It is the ability to maintain a uniform, level, and microscopic level of cut that gives modern compounds the ability to remove paint defects quickly while leaving a high-gloss finish on the paint.

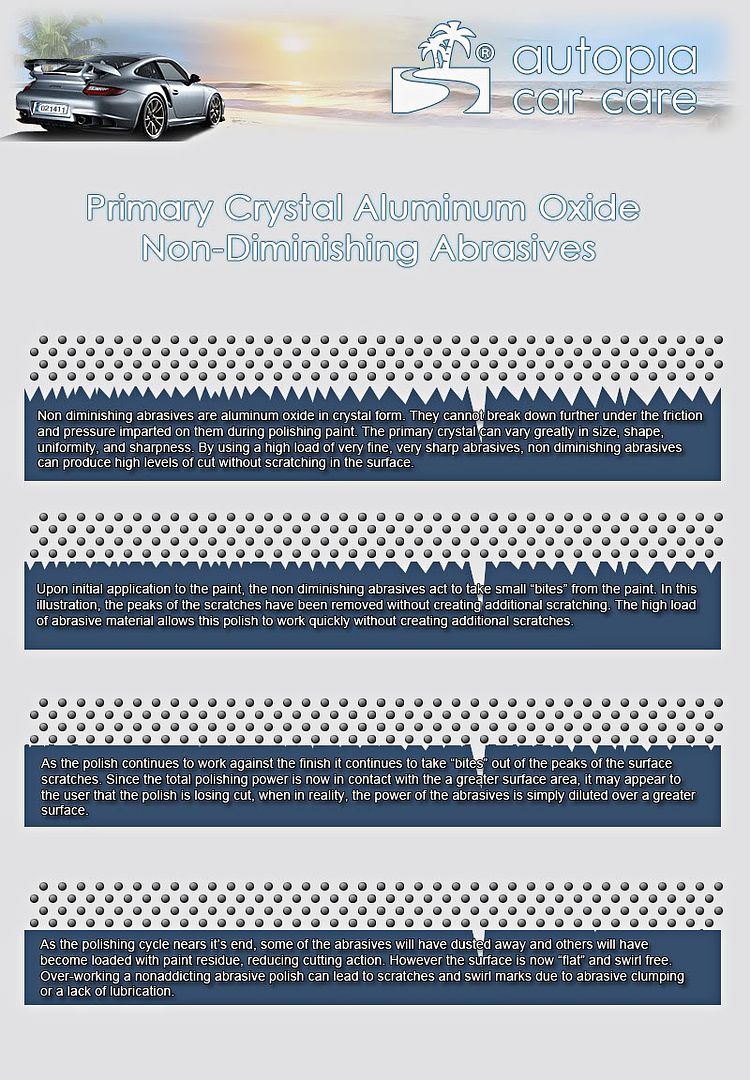

Meguiar`s M105 Ultra Cut Compound uses SMAT (Super Micro Abrasive Technology) abrasives. This lends us to the fact that these abrasives are ultra-fine, ultra-small primary crystal aluminum oxides. In crystal form the abrasive cannot dissolve or breakdown, thus the moniker non-diminishing abrasive. In order to achieve a certain level of cutting action, a large load of these ultra fine abrasives must be used in the formula.

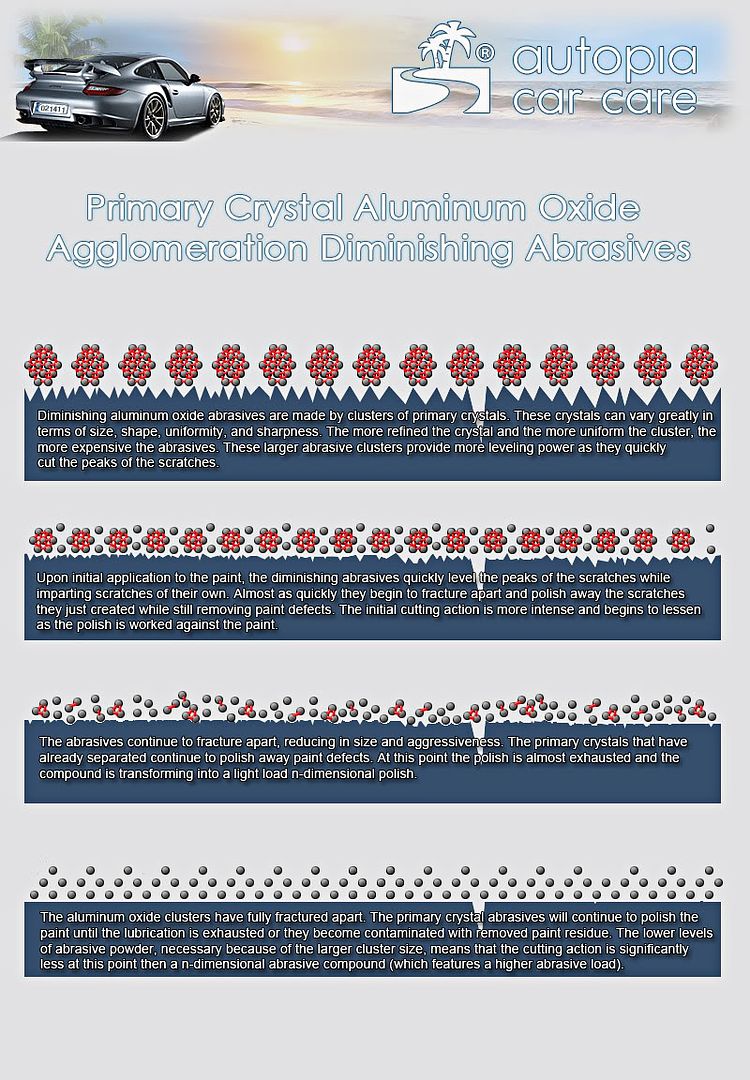

Menzerna FG400 uses, what has been described to me, as Agglomeration Abrasive Technology.

Agglomeration, according to Marian-Webster, means:

- the action or process of collecting in a mass

- a heap or cluster of usually disparate elements

In terms of polishing abrasives, this defines Menzerna as a diminishing abrasive polish. The primary crystal aluminum oxide abrasives are joined together in agglomerations in order to higher level of cutting action with less abrasive load (less abrasives in the compound). Friction will break the larger abrasives apart (fracturing) until you are left with the primary crystal abrasives.

By using modern abrasive crystal refining, Menzerna looks to be attempting offer the best of both worlds. The initial high level of leveling that a diminishing abrasive offers as well as the high quality of finish that a non-diminishing abrasive offers. By using a lesser amount of abrasive powder in the compound, Menzerna can offer a wetter product that will dust less and has a higher potential to finish paint.

Beyond The Abrasives:

The abrasives used in polish may have the most direct control over things like material removal (surface removal and surface leveling) as well as finish quality, however they only make up a percentage of the polish. The type of lubricant (usually some forum of oil-in-water emulsion or water-in-oil emulsion) and ancillary chemicals. The total result of the polish is a combination of all of the liquid (chemicals) and solids (abrasives)

A dry polish, such as Meguiar`s M105 may have a very high load of abrasive (solid) material. This will give it a high level of cut, and with carefully refined abrasives, a high quality finish, but this comes with several drawbacks as well, such as dusting and a reduced surface quality if the pad isn`t cleaned frequently. Menzerna FG400 appears to use less abrasive material (50% less then their Power Gloss Compound) which allows for a wetter more lubricated polish they may sacrifice some cutting speed but will reduce dusting and could leave a nicer finish.

Enough of the polishes on paper... Let`s see how they stack up.

Results 31 to 45 of 49

Threaded View

-

11-30-2012, 12:11 AM #1

Meguiars M105 Ultra Cut Compound vs. Menzerna FG400 Fast Gloss Compound

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

How does uber compound compare to menzerna fg400?

By brandons in forum Paint Correction and Gloss EnhancementReplies: 6Last Post: 11-16-2013, 07:53 PM -

Finishing with Meguiar`s M105 Ultra Cut Compound

By Todd@RUPES in forum Paint Correction and Gloss EnhancementReplies: 44Last Post: 11-26-2012, 10:38 AM -

Video: Acheiving a swirl free finish with Meguiar`s M105 Ultra Cut Compound

By Todd@RUPES in forum Paint Correction and Gloss EnhancementReplies: 22Last Post: 08-14-2012, 08:46 AM -

Deep Gloss Auto Salon Test: Optimum Compound II vs M105

By Deep Gloss Auto Salon in forum Car Detailing Product DiscussionReplies: 8Last Post: 07-23-2011, 12:07 AM

Reply With Quote

Reply With Quote

Bookmarks