So after reading a bunch of threads on here I got a good amount of people saying that burning the paint with a rotary is harder than everyone thinks and to not be afraid of it. Well, my lack of experience and itchy rotary trigger finger looks like got me in to some trouble. Here is what I was working on:

2000 Dodge Durango

Before:

After:

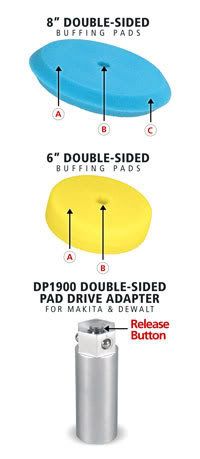

Here is when things went wrong. There is an indention going down the hood on both sides of the front hood emblem and i lifted the rotary at an angle to polish in that crease. That was a big mistake. I swear I smelled the burning right away but was in denial for a second and then it was too late. It is definitely burned right? You can`t rub it out and it looks exactly like it "burned" it. Sucks. Thank god it was a hood that I was planning on replacing due to some damage on one side. I was using a black dual sided edge pad 8 In. Double-Sided Foam Pad for Heavy Cutting - Black - DP1910 with some Right Look premium polish Premium Polish - Quart - DC1140-Q

In the end it was my mistake for lifting the pad at an angle but working it at around 1800-2000 I didn`t think it would burn like that. Rookie mistake for sure....

Anyone want to trade a Makita Rotary for a DA set or UDM????

Results 1 to 15 of 27

-

09-23-2008, 12:18 PM #1

-

09-23-2008, 12:30 PM #2

Bummer. How else would that area get polished,....by hand?

-

09-23-2008, 12:32 PM #3

Yeah, or else maybe with a 4 inch pad at really slow speeds? I really should of just slowed it down and been careful but I never thought it would happen. Lesson learned.

-

09-23-2008, 12:32 PM #4

Take a applicator pad. Use the same product you used with the wheel and hand rub that out. It dosen`t look to bad to me.

And I might add... If this is you`re first time using the ratary grab some wool pads. Foam heats up way to fast.

-

09-23-2008, 12:42 PM #5

That almost looks like you hit it with the side of the backing plate...

Only Z Best Detailing-Automotive Concours Detailing Services

http://ozbdetailing.com

https://www.facebook.com/ozbautodetailing

-

09-23-2008, 12:46 PM #6

That was what i was thinking Pats, looks like it got hit by the BP.

AutopiaForums is the place to be.

Remember to Shop Autopia-CarCare.com for your Detailing Needs!

-

09-23-2008, 12:46 PM #7

Originally Posted by Pats300zx

Originally Posted by Pats300zx

Actually this is the setup I`m using so there`s little to no chance that anything other than the pad can hit the paint. No backing plate required with that adapter.

-

09-23-2008, 12:53 PM #8

Yep, just the pad did that, no doubt.

Use wool, it`s a godsend for cutting.

I usually use my Flex or 7424 for stuff like that, as well as painted plastics.Portland, OR

-

09-23-2008, 01:06 PM #9

Well let`s see here:

You were operating at 1800-2000 rpm, you will rarely see experienced pros go above 1500 or so.

You will have a much greater risk of burning paint with a larger pad (ie. 8").

Cutting foam, like what you were using is also much more likely to burn paint than say, a wool pad.

-

09-23-2008, 01:35 PM #10

damn i learned a lot so far...great pointers everyone....

makes not to self :

start off with wool when i grab a rotary, never go above maybe 1000rpm as im learning,dont tilt the pad...

-

09-23-2008, 01:37 PM #11

Good on you that you tried, tough luck that you burnt it a bit! I`m sure you`ll have learned from your mistake and will be the better for it the next time!

Look on the bright side, you got rid of the swirls!!! Unemployed Since 2009 - Gibs Me Dat

Unemployed Since 2009 - Gibs Me Dat

[SIGPIC][/SIGPIC]

-

09-23-2008, 02:38 PM #12

this is exactly why i havent had a go with my g220 yet. apparently you cant do it with one of these?

one question was this your car?

-

09-23-2008, 02:48 PM #13

Originally Posted by Bigpoppa3346

Originally Posted by Bigpoppa3346

Ummm??? What? Where did you get any of that from? If you`re cutting you need to go as fast as it takes to cut down to where you need. I usually stay around the 1500 mark myself but I`ve been known to kick it to the 2200-2500 mark a few times to get into something. And bigger pads are more likely to burn? Just the opposite really in all of my experience. The small pads create more heat. The bigger pads can disipate the heat better over a bigger area. Just like Foam will always burn before wool. (foam and high speeds really never should mix) That part we can definatly agree on. But I`m not so sure about the rest.

Where did you get any of that from? If you`re cutting you need to go as fast as it takes to cut down to where you need. I usually stay around the 1500 mark myself but I`ve been known to kick it to the 2200-2500 mark a few times to get into something. And bigger pads are more likely to burn? Just the opposite really in all of my experience. The small pads create more heat. The bigger pads can disipate the heat better over a bigger area. Just like Foam will always burn before wool. (foam and high speeds really never should mix) That part we can definatly agree on. But I`m not so sure about the rest.

-

09-23-2008, 05:12 PM #14

1) A larger pad is more likely to burn because it is doing more work. The outside of the pad is traveling a greater distance, at a greater speed, then a small pad. A 6.5 inch pad at 1000 rpm is traveling 19.5 inchs per revolution or 19,500 inches per minute. An 8 inch pad is traveling 25 inches per revolution or 25,000 inches per minute, whichi is 20 percent quicker.

2) I usually buff between 1500-2000 rpm.

3) A large cutting foam pad, large size, and good speed + bad technique (tilting the edge which is spinning very quickly)=burn

-

09-23-2008, 05:22 PM #15

Large pads burn because the larger diameter means that at any given rpm, the linear speed at the edge of the pad is higher. The advantage of larger pads is that you don`t use the whole pad on the paint, just the edge, like an angle grinder.

So the polishing is more of a linear than circular type. You can get cutting done faster at high rpms like this but high heat pads like foam risk burning the paint more. Plus they take more skill with large pads, as they cut in only one direction to get best results you have to go over each section with 4 passes to get the pad to cut in the up, down, left and right directions, each time tilting the polisher in the correct direction. This is the skill needed to master the rotary, especially with big heads. Do it right though and you can polish a whole car hood to complete defect removal with no swirls or holograms in about 10-15 minutes. The high speed means you can use much finer abrasives, with good lubrication though, so that you don`t need the "rocks in a bottle". It`s like cutting with a finishing polish, it`ll always finish fine. This is also why 3M products are body shop type products, primarily for rotary use they utilize fine but hard polishes that can withstand the abuse the rotary dishes out without dulling, remove the defects because of the power of the machine not the polish. This eliminates a lot of the multi stepping needed with a DA.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

PC Burns

By Yaemish in forum Machine Polishing & SandingReplies: 17Last Post: 06-24-2006, 09:42 PM -

It burns It burns!!!

By TrueDetailer in forum Hot TubReplies: 9Last Post: 07-05-2005, 10:55 PM -

cigarette burns

By derek37 in forum Auto Detailing 101Replies: 1Last Post: 11-05-2004, 10:38 PM -

Cig Burns

By EdLancer in forum Car DetailingReplies: 2Last Post: 10-24-2004, 05:17 PM -

Sports car collection nearly burns in fire!

By Brad B in forum Car Show & ConcoursReplies: 14Last Post: 02-17-2004, 12:28 PM

Reply With Quote

Reply With Quote

Bookmarks