I`m working on a side project and was wondering...

What are the possible causes of micro-cracking-spiderwebbing in the headlight overs.

Overpolishing/heat. Can *too much* be wetsanded.

All of the above and then some.

For those that know more about this, feel free to chime in

Results 1 to 9 of 9

-

04-12-2013, 07:42 AM #1

-

04-12-2013, 08:20 AM #2

I`ve seen it a few times. IMO, it was most likely already there and caused by the heat from the headlight bulb heating up the lens and over time many heat cycles have taken their toll on the lens. Not much can be done to fix it besides replacement.

-

04-12-2013, 08:35 AM #3

OT....but those UV sprays looks pretty amazing. Final sand at 1500, etc - plastic still hazy. Just spray on the UV coating, cure and VIOLA....clarity back in the plastic. Ha, sounds like I just pitched a sunday infomercial on those UV coatings.

Been doing homework and then some,

-

04-12-2013, 02:27 PM #4

Originally Posted by jsoto

Originally Posted by jsoto

Note that the coating does not put clarity "back IN the plastic." As the name implies, the coating builds up ON the plastic, filling in the sanding marks (also referred to as "mechanical adhesion") and adding a protective/sacrificial layer on top of the substrate material. No magic tricks, just chemistry/physics like regular automotive paint. Charlie

Charlie

Automotive Appearance Specialist - Serving Greater Lansing, Michigan

http://www.cchautoappearance.com/

-

04-12-2013, 02:53 PM #5

I can`t quite get how the chem. happens but I get it the analogy you`re saying like when they do bodywork.

I was looking at how it just gets sanded to 1500-2000 (plastic still hazy) but after the spray/curing, the clarity was quite back

-

04-12-2013, 03:34 PM #6

Originally Posted by jsoto

Originally Posted by jsoto

A lot of people use a polish of some sort after sanding and that is what brings a lot of the clarity back. Then they use a sealant of some sort3D and HD Professional Detailing Products

-

04-12-2013, 03:40 PM #7

I usually use 1500-2500 grit wet sand then polish after then seal like said above works great!

-

04-12-2013, 03:50 PM #8

Originally Posted by jsoto

Originally Posted by jsoto

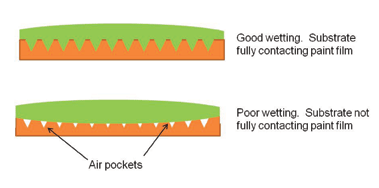

An easy way to understand how it works on a larger scale would be to compare it with self leveling concrete or epoxy; its viscosity is just thin enough for it to flow out and "fill in" the textured grooves on a surface before it dries/cures, resulting in a smooth surface.

In the case of plastic lenses, the substrate material is still "transparent" even though it looks hazy due to the sanding scratches (which alter the way light is reflected off the surface); since the UV coating is clear, once it fills in those scratches and levels out light is again able to refract through the surface instead of reflect off it -- that`s the clarity you`re looking for.

The whole idea behind leaving scratches in the lens is that it creates more surface area for the coating to adhere to, which strengthens the bond between the plastic and the resin of the coating.

See this site for a more formal description: Fundamentals of Paint Adhesion - Metal FinishingCharlie

Automotive Appearance Specialist - Serving Greater Lansing, Michigan

http://www.cchautoappearance.com/

-

04-12-2013, 04:26 PM #9

Thank you. Great read.

Ever work with SLC....

Just did 100+ 50lb bags last fall on a project...

Gotta work really fast with that. ..

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Polishing Headlights: UV Coating

By mysteryan in forum Car DetailingReplies: 24Last Post: 04-06-2009, 02:29 PM -

Polishing Headlights

By larry_bar56 in forum Car DetailingReplies: 20Last Post: 11-11-2007, 12:47 AM -

polishing headlights with PC?

By redsox03 in forum Machine Polishing & SandingReplies: 7Last Post: 04-23-2007, 03:06 PM -

Polishing headlights - What to use?

By schoi in forum Car DetailingReplies: 12Last Post: 04-03-2006, 06:27 PM -

neeed help polishing headlights

By Bill D in forum Car DetailingReplies: 18Last Post: 10-12-2003, 09:51 AM

Reply With Quote

Reply With Quote

Bookmarks