Really Todd? Other than getting into it with the guy about teflon I don`t recall any posts - maybe it was Brian.

Results 181 to 192 of 192

Thread: 8 Way Paint Sealant Test

-

04-14-2008, 06:55 PM #181

-

04-14-2008, 07:27 PM #182

Originally Posted by JuneBug

Originally Posted by JuneBug

Uhm, maybe because it just got bumped to the top after 3.5 months. Mine was a legitimate question asked in a polite and respectful manner.

-

04-14-2008, 07:30 PM #183

Originally Posted by TH0001

Originally Posted by TH0001

I`d love to know which manufacturers told you that. Just how thick do you have to apply a product for the solvents to become trapped? I can appreciate that if you try and remove the residue before the product has hazed over then you may also remove some of the polymers, but as David stated in his original post, he let the products cure for an hour before removal, enough time for even the slowest drying solvents to evaporate.

-

04-15-2008, 11:18 PM #184

Originally Posted by TH0001

Originally Posted by TH0001

Well, itââ¬â¢s actually to determine the durability of each product based on how long it beads water. I mentioned this on page 3:

Originally Posted by David Fermani

Originally Posted by David Fermani

In all honesty, Iââ¬â¢m somewhat disappointed with the results of my test too. I was hoping for distinguishable variances between each product but it hasnââ¬â¢t quite happened the way I had planned. I was also thinking that the untreated sections would flatten out really fast. But, because I prepped the surface so well AND because itââ¬â¢s a new vehicle (no surface degradation), the surface tension throughout the whole vehicle is causing the outcome to be undefined. All the initial small, tight and round beads dropped off way before the 6 week point on all the panels. Does this mean that all the protection and/or product has failed or stopped working? Thereââ¬â¢s no way of knowing! If you compare beading on protected panels from the 6 week mark to the 6 month mark, thereââ¬â¢s really not *much* of a change. This again could be attributed to surface tension and/or product remaining. Again, from discussing this test with a few formulators & enthusiasts, it canââ¬â¢t be determined. Iââ¬â¢ve also been told that itââ¬â¢s very difficult to do a product comparison on a vehicle with so many different surface/body lines. A better way would be doing it on panels that are totally flat and with large surface areas. Again, sorry this thread isnââ¬â¢t giving any real world outcomes. What it does show, is the power of low surface tension and how it could play into how we view our results.

Originally Posted by TH0001

Originally Posted by TH0001

Originally Posted by TH0001

Originally Posted by TH0001

Originally Posted by Jesstzn

Originally Posted by Jesstzn

Originally Posted by Jesstzn

Originally Posted by Jesstzn

Originally Posted by MakitaNinja

Originally Posted by MakitaNinja

Originally Posted by TH0001

Originally Posted by TH0001

Beyond Terrible & Painfully Obvious? Thatââ¬â¢s way off & not accurate in any way. I spoke to Sal Zaino in great depth today for about an hour. He was familiar with this thread and had nothing bad to say about my test and/or the amount of product I used. He specifically stated that applying too much product will NOT affect the performance/longevity. He actually laughed when I told him what was stated here (above)! I also learned that if a sealant is allowed to haze/dry properly, it won`t make any difference how thick the application is. You`ll still get the same amount of product bonding to the surface. If the solvents don`t fully evaporate before removal (i.e., if you try to buff it before it`s dry) then yes it may cause some of the polymers to be removed with the polish powder. The solvents will never become trapped just because the layer is thick, they will just take longer to dry out. Once they`ve dried, the polish powder can be buffed off and the only disadvantages will be that you`ll have wasted product and made more work for yourself in the removal.. Sal did say that using ZFX with Z2 will definitely give it much more durability, but at the time of the test, I failed to research this. So, bottom line; I feel people are grasping onto incorrect information(rumors?) and leading to more misinformation. The products I used were 100% totally dry and applying them a little heavy didn`t hurt this test. Sorry.

Todd ââ¬â Iââ¬â¢d really like to know who the 6 formulators/manufactures are so I can maybe discuss this with them too. I enjoy and try to capitalize on every chance I get in respect to learning from truly knowledgeable professionals. Can you please disclose this list?

Also, Sal mentioned that it`s vital that a vehicle gets clayed for a proper application and bonding of sealants. I noticed in your recent sealant test you didn`t clay? Why? Even though a finish is washed/ polished and Prep-Sol`d; you still will have bonded surface contaminants that will interfere with a products abilty to cross-link & bond to the surface. Especially on a 7+ year old vehicle.

Originally Posted by Alfisti

Originally Posted by Alfisti

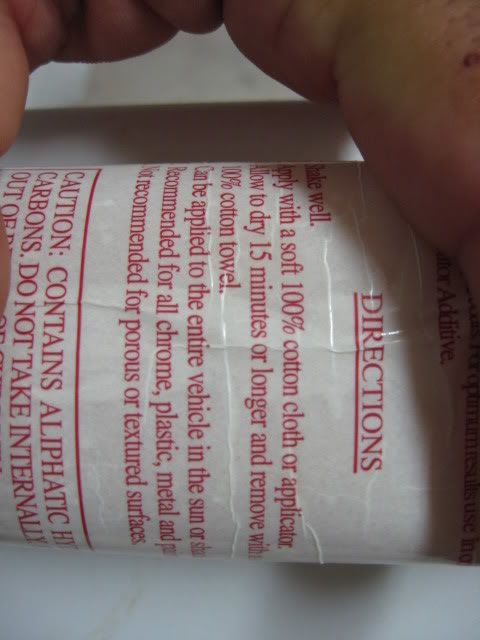

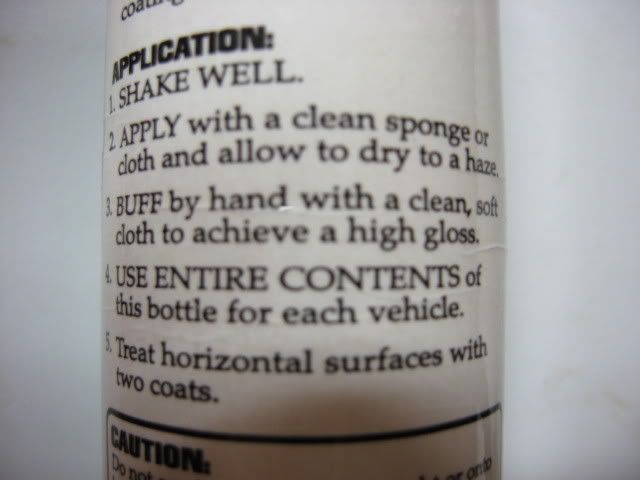

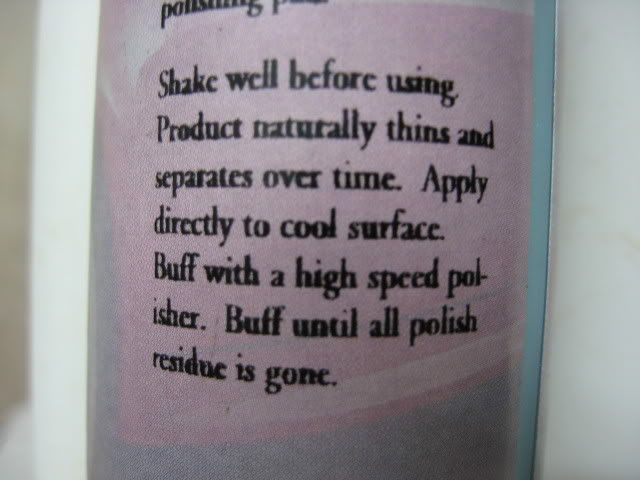

Right. Youââ¬â¢d assume that if it was that detrimental to its performance, theyââ¬â¢d list it? I`d have to say that it would be worse to under apply the product than over apply it, as you could end up with some areas that have no coverage at all. Hereââ¬â¢s the bottle labels on some of the products I used. Again, none list amounts to use and/or that using too much to be a problem.

Originally Posted by TH0001

Originally Posted by TH0001

All 8 products were applied to the vertical panels (sides) and were not compared to the horizontal sections (tops) in any real way. That would be like comparing apples to oranges. Could you explain how this skews results if they arenââ¬â¢t being compared?

Originally Posted by Black240SX

Originally Posted by Black240SX

Good idea. I might 1st clay ý of each horizontal section to see how different the beading would be. Then, later I could reseal this area to compare. I have a feeling that claying (even with mild clay) will pull/shave the top layer of the remaining sealant away; if in fact any is still there.

Originally Posted by detailjohn

Originally Posted by detailjohn

Itââ¬â¢s really hard to tell at this point whether the beading I from protection and/or surface tension from being a new vehicle (hardly any surface degradation). From the pictures, the Malco beading seems to be the most round, small and tight throughout the entire horizontal surface

Originally Posted by JuneBug

Originally Posted by JuneBug

Thanks again (as always) for your support and wit. You rock! :2thumbs:

Originally Posted by GatorJ

Originally Posted by GatorJ

Thanks. You are correct on both thoughts. This car never is parked in the garage. The sides (because of gravity) bead much differently than the tops. I only had enough room (3 body panels) to test 6 products on the horizontals. Because I also had some Menzerna & 1Z, I thought Iââ¬â¢d throw them in on the 8 possible vertical panels.

Originally Posted by detailjohn

Originally Posted by detailjohn

Great. Iââ¬â¢ve been using it on other vehicles and Iââ¬â¢ve received a lot of positive feedback from the owners. It also has a really enjoyable smell too.

Originally Posted by charger17

Originally Posted by charger17

The thanks will never end Jon! Youââ¬â¢re a very knowledgeable person.Metro Detroit`s leader in cleaning, preserving & perfecting fine automobiles!

-

04-16-2008, 12:22 AM #185

Originally Posted by David Fermani

Originally Posted by David Fermani

Wow, who knew such a test would require such an explanation, what I have learned from this site is facts are facts, and that a website will never reveal the genuine article, I think it`s great you did this to try and help people realize the durability of certain sealants. Fact of the matter is, you should probably be doing tests like this to prove to yourself what works, because when you don`t use a product like it`s suppose to be used, and some who knows better sees that, they will take it with a grain of salt regardless how tight you are with the owner of zaino. In the end some may benefit from your thread, most professional detailers will find it pointless to read based on the thread title alone, they should know what they are doing and with that said, I will waste more cyberspace.

Do what works for you and keep it simple, I lurked here for years never even imagining I would actually have to chicken peck responses but this caught me eye, you apparently have a vested interest in gaining a reputation, which will in turn be good for your detailing company, negativity doesn`t help, so in the best interest of your full time detailing company, bringing personal beliefs and somewhat of a stranglehold on product owners and manufacturers could cause adverse effects.

Follow the instructions, and better hone in on your technique and selection of products, that`s what will ultimately tell the tale of your professionalism, not battling back and forth to prove your claims worthy.

-

02-21-2010, 02:33 PM #186

WOW this guy should be getting overtime....Good work David. Cant wait to hear the results. Its hard to get a product to show protection after 4 months...at least in the North East, that has been my finding....This should prove interesting. Good Luck David.

-

02-21-2010, 05:32 PM #187

Thanks David. Pay no attention to the BS. Remember, no good deed goes unpunished!

-

02-21-2010, 05:44 PM #188

This is a thread from Oct 2007 to April 2008. I don`t expect much is going to happen here. :lol

-

02-21-2010, 06:01 PM #189

I would expect that Sal would know how his product functions. I do suspect that a non crosslinking wax if applied too thickly could result in improper evaporation of solvents and hence the possible removal of at least some of the wax portion.

-

02-22-2010, 10:02 AM #190

Originally Posted by paintxpert

Originally Posted by paintxpert

Dude, this thread started more than 2 years ago.

-

02-23-2010, 11:29 AM #191

Buff until residue is gone.... I rest my case. I buff till the panel is completely and totally optically perfect. If the paint allows. If the car is ten years old chances are you wont get it 100 percent. I get the paint as perfect as I can given the condition of the paint. I think Malco has a good product...I have seen better but its OK. I dont carry Malco with me. I do carry some ARDEX products though. I dont finish up with them either.

-

02-23-2010, 10:17 PM #192

Awsome stuff. A lot of work but in detailing what isn`t?:xyxthumbs

www.moedetail.com

The difference between a good-looking car and a great-looking car is in the small details.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

A UK version of the sealant test

By finerdetails in forum Car Detailing Product DiscussionReplies: 32Last Post: 01-13-2009, 12:38 AM -

Anyone Interested in Doing a Paint Sealant Test?

By David Fermani in forum Car Detailing Product DiscussionReplies: 57Last Post: 09-16-2007, 07:53 PM -

Wheel Sealant test

By blackTL in forum Poorboy's World ForumReplies: 4Last Post: 05-24-2005, 01:52 PM -

Wheel Sealant Test

By roadman in forum Autopia Car Care Guide To DetailingReplies: 12Last Post: 02-07-2005, 11:08 AM -

4* Wheel Cleaner review+2000 Camry test bed w/S100 Paint Cleaner and Wolfgang Sealant

By MattZ28 in forum Auto Detailing 101Replies: 10Last Post: 10-21-2004, 10:40 PM

Bookmarks