The coolant tank (for a 360 Ferrari) was sent to me by a gentleman in Virgina who had asked if I could polish it. The same principles apply if you are polishing any piece of coated aluminum.

The first thing to do is strip the coating (powder coating or clear coating) You can use an automotive aircraft stripper, just spray it on (in a well ventilated area) and let it dwell for 15-30 minutes, until the finish bubbles up.

Use a fine brush (old tooth brush) to agitate any stubborn areas where the clear coat wants to stick. Then use a plastic scrapper to remove the clear coat and wash each wheel thoroughly.

Now you will have exposed the aluminum for polishing. If your aluminum has deep gouges or texture you will want to remove those by wet sanding each; starting with 220 grit and moving up to 1000 grit before polishing. Sanding them is extremely time consuming because you want to make sure you remove all of the previous sanding marks (from the rougher grit) before moving to the next finer grit.

You can accomplish this by cross-hatching. Sanding is one direction with say 220 grit, then sand in the opposite direction (left-to-right, then up-to-down) with say 400 grit until you no longer see the 220 grit marks, and repeat finer and finer.

When it comes time to polish the wheel to a super high luster (or remove the sanding marks) you are going to need an aluminum compound (similar to a compound for paint in principle), and then follow it up with an aluminum (fine cut) polish.

The Blackfire Aluminum Polishing Kit was (to my knowledge) the first boutique line of aluminum polishes that delivers professional results to the end-user. It is an idea that has been replicated (although perhaps not equaled).

You will need to have skill with a machine polisher how ever to use it.

Here is a link to the system and directions at out store: Coming soon to Autopia-CarCare.com

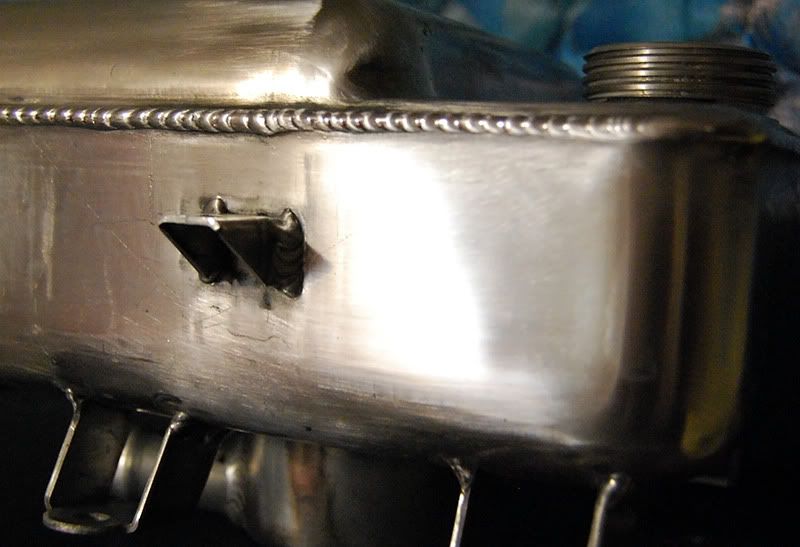

Here is a coolant tank from a Ferrari (that is actually a much cheaper casting of aluminum and much harder to polish and make look good).

The first step was using an aircraft stripper to remove the black powder coat (or in your case the factory clear). You can pick this up at just about any automotive supply store (Pepboys, Autozone, etc).

After removing all of the coating I could see that the casting was in terrible shape: factory casting scratches, texture, and deep cuts everywhere!

I tried polishing a test spot to see how the results would turn out.

The amount of gloss I was able to get from the Blackfire Polishing System was impressive and only took minutes.

However a cropped area of the photo shows that there are still a lot of these very deep (you stick the tip of a pencil into them) scratches that meant I had to sand the tank. If your wheels are not heavily scratched (or have texture) you can go right to polishing!

The right side of the tank has been sanded to 1000 grit, the rest to 400 grit. You can see the uniformity in the sanding marks (cross-hatching). I did sand a couple areas to 3000 grit, but the Blackfire Aluminum Compound is so strong that it made no difference in the outcome.

In this picture the edge of the tank (reflecting the horse) has been polished with just the compound, the rest of the tank is just sanded.

On this piece I found it easier to use a Porter Cable 7242XP (DA) Polisher and 4 inch pads. I used a Lake Country 4 inch High Gloss Yellow Pad with the Blackfire Aluminum Compound. I worked at Speed 5 with firm pressure until the aluminum was really bleeding black and the polish started to become opaque. I pays to clean the pad frequently by pressing it against a cotton towel and turning it on.

Then I followed with Blackfire Fine Cut Aluminum Polish (step two) with a Lake Country 4 inch H20 Tangerine pad, starting at step 5 then slowing to step 3 when the polish began to breakdown/dry up. Again firm pressure.

The final step was Blackfire Wet Diamond Aluminum Show Polish on a 4 inch Lake Country Hi Gloss White Pad, speed 4 with moderate pressure until almost clear.

After cleaning thoroughly I used Blackfire Wet Diamond All-Metal Sealant to lock in the shine with out the use of solvents that can dull the highly polished surface.

The results....

You can achieve a true mirror like finish on your wheels with our kit, no doubt, but it will take a little bit of time and patience ... but be warned... Polishing aluminum (and stainless) is addictive, my wife hasn`t forgiven me for what I have down to our refrigerator and appliances in our kitchen

Results 1 to 15 of 70

Threaded View

-

07-18-2011, 03:32 PM #1

Using Blackfire Metal Polishing System to create a mirror finish on aluminum

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Using the BLACKFIRE Metal Polishing System

By Todd@RUPES in forum BlackFireWax.comReplies: 17Last Post: 03-14-2014, 08:42 AM -

Using Blackfire Metal Polishing System to create a mirror finish on aluminum

By Todd@RUPES in forum Auto Detailing 101Replies: 16Last Post: 07-19-2011, 05:32 PM -

How to turn aluminum rims into mirror finish?

By JLui83 in forum Car DetailingReplies: 10Last Post: 09-18-2009, 09:29 AM -

Mirror Finish on Billet Aluminum??

By cheetoh in forum Car DetailingReplies: 3Last Post: 09-08-2008, 06:29 AM -

what process for mirror finish aluminum?

By blucpe in forum Auto Detailing 101Replies: 8Last Post: 08-12-2007, 12:25 PM

Reply With Quote

Reply With Quote

Bookmarks