Automotive paint

Paint surfaces are porous and can hold up to a pint of water after washing. They comprise contain microscopic peaks and valleys, much like the profile of a mountain range. These irregularities are known as capillary structures; there may be millions of these defects per square inch. Contaminants such as fine dirt, minerals, and pollutants are drawn into the voids where they are extremely hard to remove.

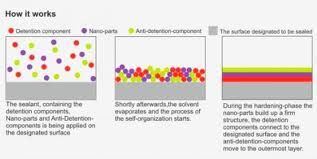

The filling of the capillary structures with nanoparticles produces a hydrophobic surface. (A hydrophobic surface is one that repels moisture.) In contrast, a hydrophilic surface is one that absorbs moisture. The potential of a surface to absorb or repel moisture is based on many factors, including: temperature, relative humidity, material ````geneity, and static electricity. Surface roughness is also a major factor; the rougher the surface, the higher the spreading rate or attraction for water. The smoother the surface, the more repellent it is to moisture.

The significance of a nano-coating is its small particle size that can form a very tight bond with the surface of most materials; including glass, paint, plastic, rubber, aluminium, chrome, stainless steel and fabrics, will have surface imperfections i.e. micro-fissures when viewed under high magnification. These undulations allow a nano-coating polymer to form a tight molecular bond (much like a printers ink when poured over paper that has writing indentations on it) with the surface itâs applied to. This level surface also improves paint surface clarity and reduce light scattering, providing improved light reflectance.

Paint sealants are synthetic products designed for long-term paint protection and easy application. They are composed mainly of amino functional polymers, which last longer than any natural wax and are highly resistant to the elements. Synthetic liquid waxes are another way of describing paint sealants. The main benefit of a paint sealant is their durability compared to a wax, polymer-based sealants will last anywhere from 3 to 6 months.

A coating is applied to a clean surface that surface takes on properties that are virtually identical to hardened glass. It is chemically inert and will not react with the base material. In other words, dirt will not bond to the treated surface, thereby reducing soiling and organic staining. Acid rain and other chemical compounds easily wash off, significantly reducing the hydroscopic nature of surfaces exposed to industrial or environmental pollution.

Nano Structure

Nanotechnology the science of nanotechnology; the creation, organization, or manipulation of materials, devices, or systems at the nanometre level

Nanotechnology, Nano particles or Nano structures, exactly what are they and how do they relate to detailing?

Most of these coatings are based around super siloxanes, and not true nanotube/tubule technology. This would cause a serious health concern for all of those - not to mention be ridiculously expensive. The context that ânano" (as related to detailing) is only as a relative size indicator merely to identify a siloxane/polymer.

They are sub micron particles that form a clear thin film of tightly packed nano particles forming an extension of the surface. The particles are up to a 1000 times denser which makes for an ultra durable hard wearing surface. Technically most detailing product particulates are not nano metre in size, although they are extremely small, as the term ânanoâ adequately describes. Single-component coatings interlace on a molecular basis and form an extremely durable protective layer on the paint surface provided they are applied properly.They also improve paint surface clarity and reduce light scattering, providing improved light reflectance

Relevant Articles

1. âNanotechnology coatings â- http://www.autopia.org/forum/autopia...-products.html

2. âCarnauba waxâ - http://www.autopia.org/forum/autopia...ml#post1476919

3. Polymers Part I - http://www.autopia.org/forum/guide-d...ml#post1469073

Results 1 to 15 of 15

-

02-19-2013, 06:43 AM #1What gets overlooked too often is that one must be a student before becoming a teacher.

-

02-22-2013, 03:38 PM #2

Great description on what Nano is really all about.

This is a simple yet affective way to differentiate between coatings!

-

02-23-2013, 07:28 AM #3

Originally Posted by Nanolex US

Originally Posted by Nanolex US

Thanks Florian

Some information on Nanolex products - Nanolex Matrix - Detailing World

Nanoflex use a Sol-Gel process of curing-

Sol-Gel

The `sol` (or solution) gradually evolves towards the formation of a gel-like dysphasic system containing both a liquid phase and solid phase whose morphologies range from discrete particles to continuous polymer networks. The sol-gel process is a wet-chemical technique used for the fabrication of both glass and ceramic materials. In this process, the solution (or sol) evolves gradually towards the formation of a gel-like network containing both a liquid phase and a solid phase.

By definition, condensation liberates a small molecule, such as water or alcohol. This type of reaction can continue to build larger and larger silicon-containing molecules by the process of polymerization. Thus, a polymer is a huge molecule (or macromolecule) formed from hundreds or thousands of units called monomers.

The number of bonds that a monomer can form is called its functionality. Polymerization of silicon alkoxides, for instance, can lead to complex branching of the polymer, because a fully hydrolyzed monomer Si(OH)4 is tetra-functional (can branch or bond in four different directions) giving it outstandingly long lasting easy-to-clean characteristics.

The water sheeting and beading is astounding, and Iâve not seen paintwork so hydrophobic before â even on the best waxes tested. I`ve not seen paintwork this hydrophobic before, even on the best waxes tested. When we sprayed or poured water onto the car it either ran immediately off and left no trace behind, or balled up into what almost looked like tiny glass marbles.

[Edit: Sol-Gel paragraph added - I will expand upon this type of curing process at a later date]What gets overlooked too often is that one must be a student before becoming a teacher.

-

02-23-2013, 07:34 PM #4

Originally Posted by TOGWT

Originally Posted by TOGWT

Surely the two statements in bold contradict? Factually, many of the coatings are highly reactive (as are the polymeric silicones, for that matter) - this is the reason for their durability. It takes much more energy/work to break the bonds to the surface.

Further, I appreciate the effort at being accessible but beware of using well defined scientific terms inappropriately to achieve it. The `stay clean` effect you allude to is not a result of chemical inertness - were that the case then things like fallout would be totally unable to adhere and we all know that a good iron-x treatment will demonstrate that this is not the case. The adherence of soiling is somewhat different. Most of these products stay clean because water does not adhere to them and thus the soils (which are most frequently carried in water) remain suspended in the water and do not deposit. You are right that the lack of adsorbed soils (or decrease) means that the effective hygroscopic character is diminished and further inhibits adherence but this is not a direct result of the surface `inertness`, rather a consequence of its hydrophobicity.

Nano particulate products do exist and are not uncommon and are not dangerous in themselves. You can buy suspensions of nanoparticles which are quite harmless and these do get used in (generic term) polish products (they are not even particularly expensive, especially when one calculates the necessary inclusion levels). These present a further problem because they are genuinely nano products but do not form strong bonds to surfaces (as detailers generally expect, and your post indicates). There are also solgel type products which are not nano as supplied (at least from one view point) but which will become nano when cured (which means that they react with moisture). These do present somewhat more of a risk (inhale them and you form nano particles in your airways and on mucous tissues) and they are more expensive, but they are presently available on the market. Indeed, some will market less complex silicone technologies as being nano but from my point of view, these people are being quite intentionally misleading. Consider that bleeding fallout removers work on a molecule by molecule basis, those molecules being no more than several nanometers in extent - comparatively, if one classes some of the sealant products as nano then it would be equally appropriate to describe Deironiser/Iron-X/Iron Cleanse/Sonax Wheel as being nano-cleaners. Realistically the term nano has become somewhat meaningless in detailing circles and tends to be a marketing rather than scientific term.

-

02-24-2013, 08:46 AM #5

`Interesting` PIPUK. Thank you for your invaluable comments and guidance, as always...

What gets overlooked too often is that one must be a student before becoming a teacher.

-

02-24-2013, 09:22 AM #6

Thanks Jon, great information.

-

02-24-2013, 01:58 PM #7

Originally Posted by Nanolex US

Originally Posted by Nanolex US

Originally Posted by POPPAJ

Originally Posted by POPPAJ

Appreciate the Likes and comments...What gets overlooked too often is that one must be a student before becoming a teacher.

-

02-24-2013, 10:51 PM #8

EXCELLENT information gentlemen.

Not trying to get off topic, but rather take advantage of a seemingly similar discussion. What impact does polishing have on microscopic peaks and valleys in the clear?Detailed Designs Auto Spa

Professional Car Detailing Atlanta

Authorized Modesta Installer

Authorized CQuartz Finest Installer

Paint Protection Film and Clear Bra Installation

-

02-25-2013, 05:29 AM #9

Dependent upon polish / compound used they will either be levelled or the edges rounded.

One of the advantages of nano sealents is that they fill the microscopic peaks/valleys, thereby producing a level surface that will reflect light evenly, producing a `mirror` type reflectionWhat gets overlooked too often is that one must be a student before becoming a teacher.

-

02-25-2013, 10:26 AM #10

I have never done a study on automotive specific polishing and surfaces but have done so on other mirrored finishes for scientific reasons. In that set of studies and supported by literature, it is actually quite hard to achieve genuinely `flat` surfaces. Using atomic force microscopy, you can look at many supposedly smooth surfaces and discover the truth is somewhat otherwise. The effect of polishing is exactly as TOGWT but it is important to realise that most car polishes are much much larger than nanoscopic because the surface aberrations tend to be notably larger than this (micron sized and sometimes milimeter) - a nano-abrasive would simply be useless against this. One requires a much larger abrasive to have effect. Realistically I doubt that nano-scale polishing would be worth doing. Reflectance measurements we did on silicon wafers showed very little optical change and it was certainly not visible to us.

Another thing one must remember about genuine nano sealants is the refractive index. This is rarely discussed but is extremely important. Even regular waxes and sealants will fill surface variations but perhaps are not so good at filling nooks and crannies. I would propose that it is the failure to do so which results in gas inclusions with multiple reflective surfaces, something less seen with nano products, which results in a less reflective appearance. Ultimately though, as noted, it is the refractive indices which define this but it is important that a formulator consider this since it is possible to diminish the color depth with excessive reflections (i.e. you reflect at the air/sealant interface, so less of the reflected light has actually interacted with the coloured layer).

It is really a fascinating area (well, to a science geek at least!).

Adam

-

02-25-2013, 12:02 PM #11

Originally Posted by PiPUK

Originally Posted by PiPUK

An exact answer to my question. Thank you.Detailed Designs Auto Spa

Professional Car Detailing Atlanta

Authorized Modesta Installer

Authorized CQuartz Finest Installer

Paint Protection Film and Clear Bra Installation

-

02-25-2013, 05:17 PM #12

Originally Posted by Jean-Claude

Originally Posted by Jean-Claude

Basic explanation of abrasive polishing

Automotive paint surfaces comprise numerous microscopic peaks and valleys, much like the profile of a mountain range. These irregularities are known as capillary structures; there may be millions of these defects per square inch. When these scratches are removed from a surface it becomes a smooth level surface that reflects light.

Scratches are identified by a grit number; "grit" is a reference to the number of abrasive particles per inch of finishing paper that are required to remove the scratches left by the grit scratches i.e. 2000 grit scratches are removed by using an abrasive rated at 3000 grit. You are actually replacing scratches with even finer scratches until they are invisible to the naked eye.

Menzerna manufacture a range of abrasive polishes from 1000 grit all the way down to 4000 grit (SF4000) these polishes contain nanotechnology ceramic micro particle diminishing abrasives that are milled to 0.3 µ (micron) They mill their own abrasives, which allows them to control the size and uniformity of the aluminium oxide abrasive used and also contain a higher abrasive content, 7% were as the other polishes contain 3% abrasives.

The abrasives are just one factor in the equation; lubricants, solvents, emulsion and their carrier system will determine the actual functional ability of the polish. Diminishing abrasive polishes are also pad âdependantâ as far as its paint correction / renovation abilities are concerned

These polishes were designed to work by utilizing kinetic (or dynamic) friction to break-down the diminishing abrasives, the more friction applied to diminishing abrasives the finer they become; this is how even micro scratches are removed. It works on the surface of paint using aluminium oxide spheres, suspended in water and hydrocarbon oils and a mechanical process to abrade the surface of the paint down to the level of the bottom of the scratch.

An extract from - TOGWT® Autopia Detailing Wiki - http://www.autopia.org/forum/autopia...-detailer.htmlWhat gets overlooked too often is that one must be a student before becoming a teacher.

-

02-25-2013, 05:55 PM #13

At what point does polishing with the finer the polish makes no sense when using nano coatings. At what point does a polish leave off and a nano coating take over improving the appearance?

Historically, paint correction experts finish a surface as finely as they can then cap it off with something that protects. Do these nano coatings change that game?Detailed Designs Auto Spa

Professional Car Detailing Atlanta

Authorized Modesta Installer

Authorized CQuartz Finest Installer

Paint Protection Film and Clear Bra Installation

-

02-25-2013, 07:01 PM #14

[At what point does polishing with the finer the polish makes no sense when using nano coatings. At what point does a polish leave off and a nano coating take over improving the appearance?]

Both; it would be a question of âperfectionâ or how far do you want to take it. Due to the way nano particulates fill surface irregularities this would produce a (hypothetical) levelled surface

[Historically, paint correction experts finish a surface as finely as they can then cap it off with something that protects. Do these nano coatings change that game? ]

Nanotechnology ceramic micro particle diminishing abrasives that are milled to 0.3 µ (micron) will finish a paint surface as finely as it`s possible; in the hands of a skilled paint renovation expert.

Some of the newer nano coating provide advanced surface (both environmental and scratch resistance) protection that is far more durable than previously available productsWhat gets overlooked too often is that one must be a student before becoming a teacher.

-

02-25-2013, 08:03 PM #15

Thanks again. Great topic and information.

Detailed Designs Auto Spa

Professional Car Detailing Atlanta

Authorized Modesta Installer

Authorized CQuartz Finest Installer

Paint Protection Film and Clear Bra Installation

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Trade: DP coating products

By success44 in forum The Swap MeetReplies: 2Last Post: 11-04-2013, 10:12 AM -

DP paint coating & other DP products

By dd1101 in forum Detailing Product ReviewsReplies: 8Last Post: 09-30-2013, 10:28 PM -

Nanotechnology coating products

By togwt in forum Autopia Detailing WikiReplies: 7Last Post: 01-27-2013, 06:48 PM -

Nanotechnology, Matrix Micro Coating?

By optimusp517 in forum Car Detailing Product DiscussionReplies: 40Last Post: 05-20-2008, 08:37 PM

Reply With Quote

Reply With Quote

Bookmarks