Research

Information regarding the care of leather is scarce, often contradictory, misleading, or simply wrong. Misinformation can lead to inadvertent damage to your vehicles leather upholstery; my goal is to present clear, concise, accurate information.

There is a great deal of conflicting information on leather care being put out by leather experts themselves who use baffling pseudo scientific techno speak as another marketing ploy, which makes it difficult to find a definitive, unbiased answer. It had always confounded me that such a simple subject has been made into something so complicated.

After various meetings and discussions with leather tanners, their chemists and fat liquoring formulators and many leather care product manufacturers Iâve gained an understanding of this versatile material on both a practical and scientific level.

I have always thought that the more facts and information you have at hand the easier it is to judge what information you are being given. After all, how can you fully understand and properly use any product unless you have all the facts? In the final analysis; itâs your vehicle, your hard earned money and your choice

Here is one definitive truth âyou are dealing with the leathers finish, not the hide itself.

Definition [: to supply water in order to restore or maintain fluid balance:]

Leather Tanning Process

Is the process which converts the protein of the raw hide or skin into a stable material which will not putrefy and is suitable for a wide variety of end applications. The principal difference between raw hides and tanned hides is that raw hides dry out to form a hard inflexible material that when re-wetted (or wetted back) putrefy, while tanned material dries out to a flexible form that does not become putrid when wetted back.

Leather is hygroscopic (naturally absorbs and retains water), meaning itâs also susceptible to losing the moisture necessary to keep it pliant and soft. The denaturing process of leather tanning removes moisture from the hide; water-based products restore the lost moisture of leather hides to maintain its natural flexibility.

Fat liquoring

Leather, at the time of completion of the tannage does not contain sufficient lubricants to prevent it from drying into a hard mass. Almost all light leathers need a greater softness and flexibility than is imparted by tannage. This is attained in the fat liquoring process by introducing oil into the leather, so that the individual fibres are uniformly coated. The percentage of oil on the weight of leather is quite small, from 3-10 %. The precise manner in which this small quantity of oil is distributed throughout the leather materially affects the subsequent finishing operations and the character of the leather.

These fat liquoring formulas are closely held secrets, passed down through generations; this is the origin of the new car âleather smellâ. This is one reason why one company`s leather can have a totally different feel, fragrance, texture and softness from another company`s product. Modern leather tanning methods; chrome tanning, seals the hides âlocking inâ the necessary fats and oils

Every leather tanner has his own, unique, blend of tanning oils. These formulas are closely held secrets, passed down through generations; they are neither volatile nor migratory, this is the origin of the new car âleather smellâ. This is one reason why one company`s leather can have a totally different feel, fragrance, texture and softness from another company`s product

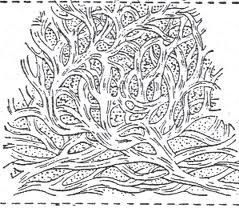

Microscopic view of the Corium (Fibres)

Leather Hides

Leather is the fibrous corium or structural part of animal skins as shown above in microscopic cross-section. For a material that is so versatile, stylish and practical you could be fooled into thinking it is an extremely complicated material...far from it.

There are basically just three main materials from which hides and skins are made: water 60-65%, protein 25-30% oil and fats 5-10%. The protein is mainly collagen (found in many cosmetics) and it is this collagen that is transformed into leather by the tanning process.

Raw hides have four main parts - an epidermis, grain, corium and flesh

Two of these layers, the epidermis a thin protective layer of cells during the life of an animal) and the flesh are removed during tanning by a process called liming.

This leaves just the grain and the corium, that are used for automotive leather upholstery .The grain layer is made of collagen and elastin protein fibres and its structure varies quite a bit depending on the age, breed and lifestyle of the animal. The grain carries many distinctive marks such as insect bites, growth marks and wound scars giving the leather a unique appearance.

The corium is packed with collagen protein of the most abundant proteins in tissues such as skin, bone, ligament and tendon where it occurs predominantly in the form of large elongated fibres called fibrils that are arranged in larger bundles and interwoven to give the structure great strength, and its structure varies quite a bit depending on the age, breed and lifestyle of the animal. It also provides excellent elasticity and durability.

In the tanning process these fibres and impregnated with collagens and polymers that are designed to hold them together and keep them supple. Much of the suppleness of leather comes from its moisture content. After tanning the skin is protected with a thin pigmented (colour) urethane and then a clear abrasion resistant topcoat.

The thickness of the corium increases with age which is why calfskins are thinner, smoother and softer than the hides of mature animals. Hides from cows are smoother, thinner and softer than the hides of mature male bull hides which are thick, tough, course grained and very strong.

When corium fibrils lose moisture they shrink, when they are hydrated with water moisture they swell. The best way to care for finished leather and to keep wrinkles to a minimum is to keep the leather properly hydrated and avoid, as much as possible, these shrinking and swelling cycles. Keeping leather hydrated only requires a regular wipe down with a damp cotton towel

Finished Leather

There is a great deal of conflicting information on leather care being put out by leather experts themselves who use baffling pseudo scientific techno speak as another marketing ploy, which makes it difficult to find a definitive, unbiased answer. Here is one definitive truth âyou are dealing with the leathers finish, not the hide itself. The use of oils, replacement of fat liquor, oil-based conditioning, proteins or the adjustment of pH levels is totally unnecessary; the surface is a urethane that contains pigmentation (colour) it neither needs or benefits from any of the above

It is somewhat of a pity any finish at all has to be put on leather as in its fully tanned but unfinished state it feels and looks superb. Unfortunately though in that condition it is absorbent, can be affected by strong light and is prone to attracting soil and becomes very dirty

Unless a Premium Leather option was purchased Isocyanate based ethyl carbamate (urethane) finished leather upholstery is used by 95% as OEM in modern automobiles. It comprises a multi stratum acrylic and polyurethane resin binder system covering over the leather hide; the top strata are the surface pigmentation (colour) and an abrasion resistant urethane is used to improve flexibility, fastness and adhesion to the leather. It absorbs water vapour but it doesn`t readily absorb liquid, so rain will not harm it and a damp cloth can be used to keep it clean.

Two or three aqueous (water- based) pigmented base coat are applied and then finally a clear aqueous (water- based) top coat is applied as the final stage of the finishing process, which usually includes additives to give it a soft feel (patina) and abrasion resistance, as well as a limited amount of âslideâ to assist in entering and exiting the vehicle

It also has micro-pores that allow transpiration (evaporation and hydration; the passage of water vapour through a membrane or pore) they are not sealed per se. Oils are not compatible with water-based pigmented urethane coatings and their molecules are too large to permeate, so they remain on the surface to be removed by clothing

Real leather has a recognizable fragrance that is missing from polyurethane and plastic. Simple cleaning and protection steps that will prolong the life of finished leather; urethane doesnât require conditioning or rejuvenation

Modern tanning and coating processes leave leather dynamic and self-regulating with regard to the moisture content therein. Repetitive heat cycling causes the leather to lose moisture, resulting in the formation of creasing or surface cracks, which further leads to the leather shrinking; however the urethane remains stable, which may lead to delamination,

Leather Conditioning

Leather is the hide removed from a deceased animal and the tanning / curing processes used seal in the necessary oils during the fat liquoring stage, thereby ensuring that the fibres cannot nor, do they need to be fed. Hide foods are something again that can be used in the horse and saddle business or with the older Aniline type dyed leathers.

There are numerous leather conditioning products in the marketplace, and they generally have the same overall function: to preserve the aesthetics of leather. However this can be better accomplished by replacing moisture (hydration) lost through evaporation.

There is no correlation between the cosmetics used for skin care and how we look after finished leather upholstery, Proteins, Collagen, Lanolin, Oils and Aloe are used for human skin reconstruction and nutrition, finished leather is not like human skin, its dead and cannot be regenerated or revived.

[Finished leather is a very chemically complex material, and if the conditioning product is incompatible it can have a damaging effect; peeling and / or cracking of the finish, colour transfer ("crocking"), yellowing, and general degradation are some of the problems that can be caused by the application of an improperly formulated, incompatible leather treatment product] Leather Research Laboratory

When corium fibres lose moisture they shrink, when they are hydrated with water moisture they swell. The best way to care for finished leather and to keep wrinkles to a minimum is to keep the leather properly hydrated and avoid, as much as possible, these shrinking and swelling cycles. Keeping leather hydrated only requires a regular wipe down with a damp cotton towel

Hydration

Leather naturally absorbs and retains moisture vapour, meaning itâs also susceptible to losing the moisture necessary to keep it pliant and soft. One of major attribute is its ability for transpiration (allowing the movement of moisture back and forth (evaporation and hydration), which it does even better than wool.

This means not just its permeability to air but its permeability to water vapour, on the other hand, whilst it absorbs water vapour it doesn`t readily absorb liquid, so a light rain will not harm it and a damp cloth can be used to keep it clean, however the introduction of any solvent-based products accelerates aging of the leather.

Water-based products to a certain extent hydrate finished leather, more so on perforated leather. Water molecules are smaller than the micro pores in urethane, so it can permeate the finish in vapour form. This is essential to transpiration (evaporation and hydration) to maintain a moisture balance as well as the suppleness and leathers natural flexibility, keeping finished leather at its optimum physical performance level, along with softness and strength

Ensure that the surface of the finished leather is clean and dust-free. Fill a fine mist atomizer spray bottle (Kwazar Mercury Pro) with distilled water; lightly mist the surface and then using a damp 100% cotton towel wipe the surface

There is no valid reason to use oil-based leather care products to condition or feed leather hides. Leather only requires hydration; but the widespread sale and use of leather conditioners remains prevalent as it is such a big and profitable industry the manufacturers continue to encourage and promote the use of their products

Urethane Surface Cracks

As the leather hide loses moisture, it begins to shrink and stiffen. This leaves a miniscule gap (delamination) between the leather hide and the pigmented (colour) urethane coating on top of it. The urethane coating is no longer supported by the hide; without proper support, it starts to crack.

Leather Softness (Patina)

This product is often used to solve the complaint that the leather doesn`t feel as soft as the floor model and similar comments. Can also be used to restore the tactile feel of older leathers and improve the feel of dehydrated stiff leathers. Leather Master⢠Soft Touch (ex Vital) - this is not a conditioner per se but is used to improve and maintain the tactile feel and lustre by rehydration and to ensure the leather remains matte, soft and supple.

It can also be used when doing repair work to help soften the area being worked on and to dilute some of the pigments, helping them to permeate. Apply a small amount to dry 100% cotton micro fibre towel, allow 20-30 minutes and then wipe surface with a dry 100% cotton micro fibre towel.

Schedule

The age and general condition of your leather and its environment will determine how often it should be hydrated. The recommended frequency for hydration is a function of the environment. For example, in an automobile, the head rests and top of the rear seat backrests tend to dry out very quickly due to direct, prolonged sun exposure.

Ideally it should be initially thoroughly cleaned and hydrated so that it`s in as best condition as possible and then simply regularly maintained to keep it in that condition. Monthly leather hydration of cars in Florida, Texas and Arizona, especially during the summer months, would not be out of line. In a northern climate or during winter months the interval between conditioning could be extended 90 to 120 days.

It can be vacuumed and maintained weekly or monthly depending on the usage of the vehicle and owners requirements.

Rain Ingress Damaged Surfaces

There are no leather finishes that are water proof. Leather hides used for automotive upholstery consist of approximately 45 square feet, that are stitched together to form a covering. The thousands of stitch holes allow any standing water to be absorbed and migrate laterally under the urethane finish. The perforated leathers used on many BMW, Mercedes-Benz, Porsches and other cars also allow standing water to permeate the urethane.

Rain ingress by inadvertently leaving a moon roof or vehicles windows open during a rain storm will very likely soak the leather seating and perhaps the carpets. The damage would depend on how long it`s exposed to water. Left for a couple of weeks your whole interior would probably have to be replaced.

Finished leather (urethane pigmentation) is water resistant, which means if you spill or allow liquid onto the surface and clean it right away it should not cause problems. Damage to the electronics that are under the seats (seatbelt sensor, seat positioning motor, air bag sensors, and etc) may be a cause for concern.

Obviously the amount of damage could be lessened dependent upon how quickly action was taken. If you saw it immediately, and got it home quickly and dried it out using towels to soak up the rain water, most things would be okay.

Avoid flexing or bending the leather while you are restoring it because leather is weakened when the fibres are dry and it may crack.

Wet a towel with warm water, wringing out excess. Proceed to wipe the leather to remove any dirt and moisten the surface. If you are working on a large item, do one section at a time so you can apply Leather Master⢠Soft Touch (ex Vital) while the surface is still moist. This is not a conditioner per se but is used to improve and maintain the tactile feel and lustre by rehydration and to ensure the leather remains matte, soft and supple.

Apply a small amount to a clean, damp 100% cotton micro fibre towel, use a circular motion and slight pressure to ensure the product permeates the dried-out pores, but do not push hard enough to damage the leather. Allow 20-30 minutes dwell time and then wipe surface with a dry 100% cotton micro fibre towel.

Although water (hydration) is good for leather and is what keeps it in good condition generally when its fibres become over soaked they swell and become deformed. When they dry they may not shrink back and revert to their original form and so become more brittle and distorted. Unfortunately at this stage it may be impossible to rectify.

Three Step Leather Care

Simple cleaning, hydration and protection are the three steps that will prolong the life of finished leather;

Urethane doesnât require conditioning or rejuvenation; always keep in mind that youâre dealing with the finished coating on the leather and not with the leather hide itself

1. Clean - there are two cleaning-related factors that can cause your leather to wear prematurely. The first is dirt, and the second is oil, combined they become very abrasive, as dirt / grit and subsequent friction cause the finish to wear2. Hydrated â when leather tannerâs talk about conditioning leather they are referring to its moisture content, re-hydration is used to restore or maintain fluid balance (transpiration and evaporation of moisture); not the replenishment or replacement of the fat liquoring, oils and / or waxes.3. Protection - is essential as it will protect the surface finish, without hindering transpiration, while acting as a sacrificial layer; this way you are not actually cleaning the Leather`s original surface, but cleaning from the surface of the protection. It also makes dirt easier to clean off

Pigmentation (Colour) Renovation

To reiterate all finished leather that is used as automotive upholstery is multi-stratum finish that comprises: a water-based pigmentation and a thin flexible urethane protective coating. Finished leather will eventually wear and fade. Light surface cracks will appear, which causes the leather to look old and deteriorated, but the leather itself is still in good condition. All that is needed to restore the finish is to renew the urethane coating (See article âLeather Restorationâ)

Bibliography

1. Leather Technician`s Handbook by J.H. Sharphouse

2. Practical Leather Technology by T.C. Thorstensen.

3. Books on Leather - http://www.shoetrades.com/dev/leather.php

4. How to keep Luxurious Connolly Leather Young and Supple. Krysti Pavlisko 1998

5. How to Restore Auto Leather. D Briggs 2001

6. Detailing your car for concourse competition Chuck & Sandy Imperatori

7. Irving Tanning Leather Glossary

8. Learning Centre a division of TCP GLOBAL/Auto Body DEPOT

9. Leather Care Facts Leatherique 2003

10. IICRC S300 Leather Cleaning Method

Information resource

1. Wikipedia Encyclopaedia

2. American Leather Chemists Association, various technical papers / articles

3. Leather Care Facts. Leatherique 2003 - Home Page | Leatherique Restoration Products

4. The Leather Institute (Townsend Leather Group) Leather Institute: Home

5. Article in the Leather Training & Technical Dept Ltd website -

6. IICRC Reference Guide for Professional Upholstery Cleaning (IICRC S300)

7. Upholstery cleaning is based upon methods recommended by the Carpet and Upholstery Cleaning Institute (CUCI)

8. The Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH)

9. Leather Research Laboratory , University of Cincinnati, Cincinnati OH

10. Society of Leather Technologists and Chemists (SLTC) various technical papers / articles

11. Leather Master⢠- Leather Master UK

12. Leather Magic⢠- Leather Magic Leather Repair Cleaner Conditioner dye Restoration and Protection Products

13. Global Care Solutions, LLC , 354 Hiatt Dr, Palm Beach Gardens, FL, 33418 - 1-800-292-3777

14. IICRC Course Descriptions: Leather Cleaning Technician - Welcome to the Institute of Inspection, Cleaning and Restoration Certification! The Certifying Body for the Inspection, Cleaning and Restoration Industry, Representing Certified Firms and Technicians World-Wide - International

15. Automotive Detailing Inside & Out; a Knowledge Base for the Perfectionist, by Jon Miller aka TOGWT

16. TOGWT ® Series of Detailing Articles, by Jon Miller aka TOGWT

Material Resources

1. Leather World Tech (Dyes (Pigments) adhesives, and etc - Glues & Adhesives - Leather Couch Cleaner : Vinyl Repair Kits : Leather Dye : LeatherWorldTech.com

2. Leather Pigments (Dye) â Leatherequi.com

3. World Upholstery & Trim - World Upholstery & Trim, U.S.A. Manufacturer of Auto Uphosltery, Carpet, Convertible Tops, Car Seats, Headliners & Door Panel Parts for Mercedes, BMW, Porsche, Jaguar, Fiat, Ferrari and Alfa. 800-222-9577

4. Leather Magic! ⢠Leather Repair System -. Leather Magic leather repair care restoration dye products

5. Replacements leather car seat covers GAHH: Convertible Tops, Auto Interiors, Quality Convertible Tops

6. Customized Factory Interiors- (Welcome to LeatherSeats.com

7. Leather Restoration Tools & Supplies - Hog Ring Pliers | Frost Auto Restoration Techniques

Related Articles

1. âReference sources and bibliography used for leather articlesâ - http://www.autopia.org/forum/autopia...ml#post1474865

2. A Brief History of Leather - http://www.autopia.org/forum/guide-d...ml#post1463189

3. Leather Tanning Process - http://www.autopia.org/forum/guide-d...ml#post1455796

4. Leather Fat Liquoring and Conditioning - http://www.autopia.org/forum/guide-d...ml#post1462908

5. Leather Restoration / Renovation - http://www.autopia.org/forum/autopia...ml#post1479003

6. âTypes of Leather Used in Automobilesâ - http://www.autopia.org/forum/autopia...ml#post1474058

7. âLeather Surface Identificationâ - http://www.autopia.org/forum/guide-d...ml#post1451654

8. Various Leather Surface Conditions and Correction - http://www.autopia.org/forum/guide-d...orrection.html

9. Leather care products - http://www.autopia.org/forum/guide-d...ml#post1465895

10. Removing Stains from Leather - http://www.autopia.org/forum/guide-d...ml#post1468879

11. Proper Finished Leather Cleaning and Care - http://www.autopia.org/forum/guide-d...ning-care.html

12. Leather Conditioning - http://www.autopia.org/forum/guide-d...ml#post1454835

13. Using Oil-based Leather Care Products - http://www.autopia.org/forum/guide-d...ml#post1450942

14. Aniline Leather; Cleaning and Care - http://www.autopia.org/forum/guide-d...ml#post1455011

15. Perforated (Nappa) Leather; Cleaning and Care - http://www.autopia.org/forum/guide-d...ml#post1455017

16. Alcantara Cleaning and Care - http://www.autopia.org/forum/guide-d...ml#post1455020

[Edit: 07.11.12 - General Revision / Update]

Results 1 to 1 of 1

Thread: Hydration of Finished Leather

-

06-21-2012, 10:19 AM #1What gets overlooked too often is that one must be a student before becoming a teacher.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Unfinished vs. Finished leather

By togwt in forum Autopia Detailing WikiReplies: 0Last Post: 06-24-2013, 05:12 PM -

Using Woolite® to clean finished leather

By togwt in forum Autopia Detailing WikiReplies: 4Last Post: 07-23-2012, 11:11 PM -

Automotive (Finished) Leather Upholstery

By togwt in forum Autopia Detailing WikiReplies: 0Last Post: 06-28-2012, 08:26 AM -

Is coated leather the same as finished leather?

By III in forum Car DetailingReplies: 1Last Post: 05-20-2006, 04:42 PM -

products for finished leather not for unfinished leather?

By White95Max in forum Car Detailing Product DiscussionReplies: 20Last Post: 05-27-2005, 12:44 PM

Reply With Quote

Reply With Quote

Bookmarks