Choosing the best machine polisher for your needs is a daunting task. There are many terms associated with machine polishing and the types of polishers that for a novice it is often overwhelming: D/A, circular, defects, jeweling, pads, rpm, pressure, speed, opm, rotary, forced rotation, orbital, passes, two mode, variable speed, ETC.

Choosing the best polisher requires answering a couple of questions.

-One, how much experience do you have or do you have any prior experience machine polishing?

-Two, what are you looking to accomplish by machine polishing?

-Three, how frequently will you be machine polishing your car.

-Four, how much time are you willing to invest in machine polishing.

What is a machine polisher and what is it used for? For automotive use, a machine polisher is a tool that moves a media (polishing pad, applicator, sand paper) against a surface (paint, glass, metal). Machine polishers, when used on paint, are used to increase the appearance of the paint by working an abrasive polish against the paint or applying a thin layer of wax or sealant.

What are the different types of machine polishers? Machine polishers are defined by the type of movement or action the machines produce. Orbital polishers are single action machines, meaning they move in one repeating direction, and mimic the tight circles of a hand. Rotary polishers are also single action machines, but act to spin the pad at a high rate. In between an Orbital Polisher and a Rotary Polisher is a Dual-Action Polisher. These polishers combine the tight circles of an Orbital Polisher with the spinning motion of a Rotary Polisher. Dual-Action Polishers can be random in nature, that is the spinning of the pad is controlled by physics, or forced rotation, where the pad is mechanically driven to spin.

Orbital Polisher

Orbital Polishers mimic the motion of hand polishing. This older style of polishers are difficult to find and often lack the power necessary to polish the surface and remove paint defects , although they work well for applying and removing gloss enhancing glazes, sealants, and waxes. These polishers are available at most parts stores and outlets.

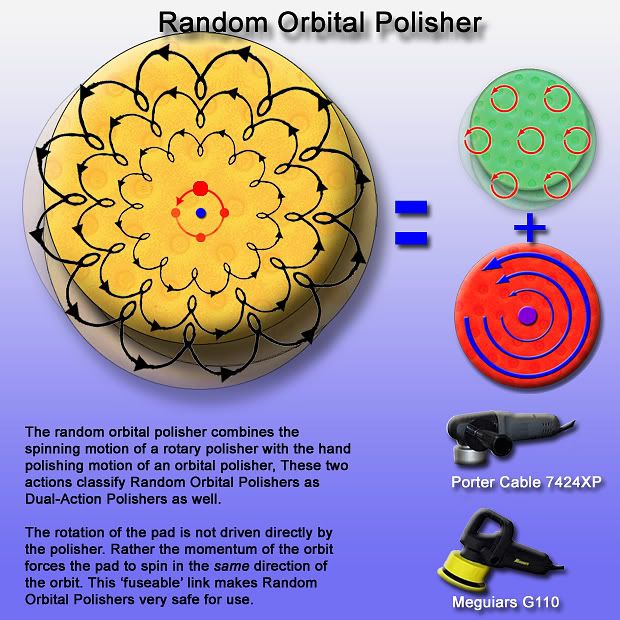

Random Orbital Polisher

Random Orbital Polishers such as the Porter Cable 7242XP and Meguiar`s G110 are dual-action polishers that combine the movement of an orbital machine with the spinning motion of a rotary polisher. The speed of the polisher is rated in orbits per minute or OPM and is variable via a selector dial; This gives Random Orbital Polishers the ability to effectively polish the paint as well as apply waxes and sealants.

The pad is not forced to spin; the machine only controls the orbit of the pad. Instead the momentum created by the high speed orbital motion causes the pad to rotate in the same direction as the orbit. There is no direct link, making these polishers very safe for novices. The combined motion creates a curly-q pattern the pattern that is `m` shaped. The pattern is infinitely variable depending on the number of orbits that occur during the rotation of the pad. This is a factor of the stroke length, the pad size, and how much grip the the pad has to the surface. This variable constantly changes pad is moved across the paint`s surface creating a truly `random` pattern.

Using a smaller diameter pad or a pad with a stiffer structure will allow the pad to spin at a faster rate allowing the machine create a powerful polishing motion.

Advantages: Random Orbital Polishers feature interchangeable backing plates which allow the mounting of various polishing pads and polishing pad sizes, as well as carpet brushes and other accessories. Variable speeds make Random Orbital Polishers very versatile and well suited to polishing away paint defects and applying waxes and sealants.

Disadvantages: Random Orbital Polishers lack the power to remove large amounts of paint quickly, limiting their effectiveness when polishing out significant damage.

Bottom Line: Random Orbital Polishers safely produce good results for beginner polishers. There is a slight learning curve to learning this polisher, as an increase in experience and using different techniques and polishes will allow these style polishers to produce amazing results. It is easy to learn and challenging to master.

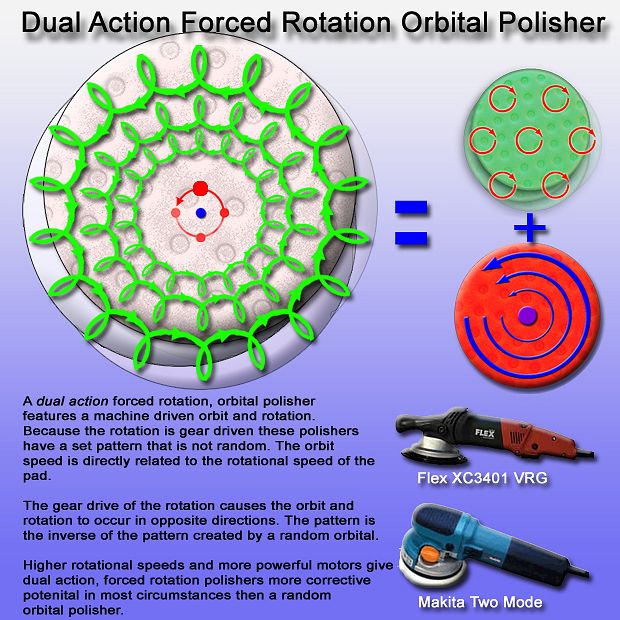

Forced Rotation Dual-Action Orbital Polisher

Forced Rotation Polishers such as the Flex XC3401 VRG or the Makita Two Mode are Dual-Action Polishers which combine the motions of the orbital and rotary polisher. The difference between these (forced rotation) polishers and Random Orbital Polishers, is that these polishers drive both the orbit and the rotation of the pad.

The forced rotation of the pad marginally increases the risk of damaging the paint from heat build up or from the the edge of the pad contacting the paint. However the motion of the machine still makes it a very safe choice and ideal for novices. The number of orbits is directly related to the number of rotations of the pad, therefore the pattern the machine produces is not random. A gear drive forces the pad to rotate in the opposite direction of the orbit creating a pattern that is the inverse of a Random Orbital Polishers; A `w` pattern.

The increased power of Forced Rotation Dual-Action Orbital Polishers gives them an advantage in polishing power over their Random Orbital counterparts in most circumstances. While they are slightly more difficult to control because the forced rotation will drive the machine across the paint, the repeating pattern of the machine allows beginning polishers to achieve near optimum results from the get go.

Advantages: The increased power and forced rotation will allow these polishers to produce results faster then a Random Orbital Polisher in most cases. The fixed pattern of movement makes microscopic marring difficult to see, eliminating visible holograms in most cases. Can be used to polish out paint defects as well as apply glazes, sealants, and waxes.

Disadvantages: Forced Rotation Dual-Action Polishers do not feature traditional backing plates that be exchanged for other sizes. The fixed rate of rotations per orbit can limit the power of these polishers in certain circumstances.

Bottom Line: While slightly more difficult to control, Forced Rotation Dual-Action Polishers are ideal for beginners because they produce more consistent results regardless of inconsistencies in technique. The orbital/rotary motion greatly reduces the risk of creating buffer trails, allowing for more consistent finishes on the paint.

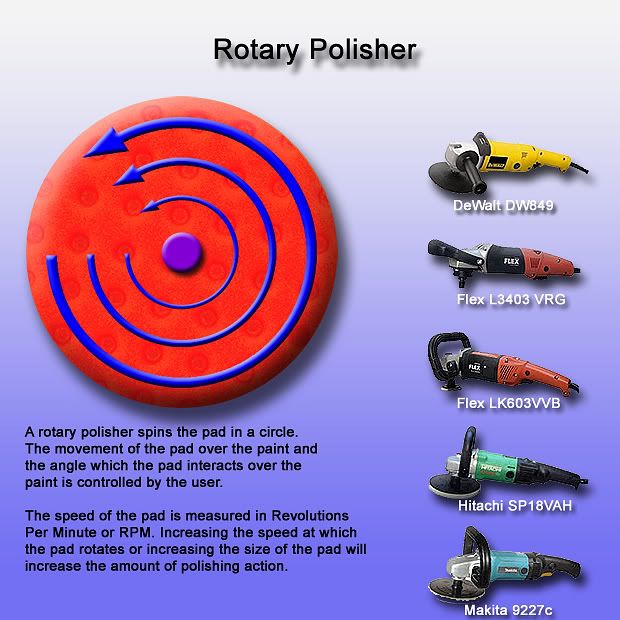

Rotary Polishers

Rotary Polishers are sometimes referred to as circular or high-speed polishers because they spin the pad at high rate. This direct polishing action eliminates all variables associated with Orbital or Dual-Action Polishers. The direct spinning action of the pad creates more friction on the paint resulting in an increase of surface tempature. The power and motion of the machine increases the risk of damaging the paint in the hands of less experienced users.

Rotary polishers require more time to learn, but those who use them will tell you that it is time well spent. The power and direct control of the machine allows the artists who use these machines to create some of the most perfect paint surfaces in the world. Rotary polishers break down polishes (particularly traditional polishes) in the most even and efficient manner, and the speed which they polish cannot be matched with the other styles of machines. Nothing has the potential to create stunning finishes and remove severe damage faster then a rotary polisher.

Advantages: Rotary polishers are the most powerful polishers and are capable at removing defects quickly and efficiently. The direct motion of the machine gives the user infinite control over the polishing action, allowing experienced users to create stunning finishes.

Disadvantages: Rotary polishers produce a repeating pattern as they work against the paint which increases the risk for damage and creates microscopic scratches known as holograms that are visible on some paints. These polishes possibly offer the highest potential but require the most experience to achieve that potential The spinning motion is not ideal for applying waxes or sealants.

Bottom Line: Rotary polishers are ideal for those who have the time to learn the machine. The users experience and skill is directly responsible for the results achieved, which can be a benefit or a negative depending on who is viewing it.

Results 1 to 13 of 13

Thread: Choosing a machine polisher

-

07-29-2009, 10:32 PM #1

Choosing a machine polisher

-

07-29-2009, 11:05 PM #2

Excellent!!!:drool5::thumbup::thumbup::thumbup:

Bill Luster

Specializing in Detailing Corvettes....:thumbup:

You`ve been given one life.

Think about it.

-

08-26-2009, 10:58 AM #3

-

08-26-2009, 12:18 PM #4

Thank you Todd for this awesome write-up on this topic many have.:clap:

AutopiaForums is the place to be.

Remember to Shop Autopia-CarCare.com for your Detailing Needs!

-

08-26-2009, 12:40 PM #5

-

08-26-2009, 01:22 PM #6

Nice job Todd.

Phil

2002 Silver Audi S8

"I raced back in a time when racing was dangerous, and sex was safe." - Sir Jackie Stewart

ProperAutoCare

Manufacturer of Blackfire and Eimann Fabrik

-

08-26-2009, 05:22 PM #7

I have 2 rotaries (both of which I need, little flex for tight spaces, makita for heavy stuff) and the Flex 3401... is the Flex DA too powerful of a machine, or shall I say "not the ideal" machine to use with the KB method, or surbuf pads etc? I am really interested in all the correction power many are getting with their PC`s, can the Flex DA replicate that with slight adjustments or should I sell it and buy a new PC? To be honest what I can sell the flex for will most likely pay for a brand new PC machine.

LMK, thanks!

-

08-29-2009, 11:18 AM #8

-

08-29-2009, 11:29 AM #9

The KBM way:thumbup:

AutopiaForums is the place to be.

Remember to Shop Autopia-CarCare.com for your Detailing Needs!

-

08-31-2009, 06:54 PM #10

Kevin recommends using the Random Orbital for various reasons. Many people have used M105/M205 with a Flex had have gotten great results, in fact we sell a kit with the Flex. Use enough pressure to compress the pad (so that the pad transfers the motion of the machine) and back off the speed off to 4 or 5.

The Surbuf pads, however, tend to work much better with a Random Orbital Polisher vs. a forced rotation polisher.

The Flex is definetely the more powerful machine, but since I have used Kevin`s suggestions, I find that I can often get as much defect removal with a PC. If you have the Flex, I would probably stick with that, instead of loose value with going to a PC. Ideally you would have both!I am really interested in all the correction power many are getting with their PC`s, can the Flex DA replicate that with slight adjustments or should I sell it and buy a new PC? To be honest what I can sell the flex for will most likely pay for a brand new PC machine. Should you do that, call Angelo first, and he can set you up on our detailer program (up to 25% on some products)

Should you do that, call Angelo first, and he can set you up on our detailer program (up to 25% on some products)

-

09-01-2009, 10:30 AM #11

I just got a flex DA and it makes my UDM (original model) feel like a toy. I just have used it on one test spot but I liked the results a lot better. I need to get some time with it to see if it consistently finishes, The polish (PO85RD) sure did break down faster with the Flex. Before it seemed to take forever on my UDM. I may have just been too gentle with the UDM....

Al

Made in USA

-

09-01-2009, 10:38 AM #12

Nice to see you moving up AL on your machine`s, next one should be a rotary!

AutopiaForums is the place to be.

Remember to Shop Autopia-CarCare.com for your Detailing Needs!

-

09-03-2009, 09:39 AM #13

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

New machine polisher

By Sparky123 in forum Machine Polishing & SandingReplies: 9Last Post: 09-15-2014, 03:35 PM -

Choosing the right style and type of DA polisher

By Todd@RUPES in forum The Detail Institute presented by Autopia-carcare.comReplies: 26Last Post: 10-15-2012, 07:24 PM -

Choosing a new polisher. Flex 3401 or Dewalt 849x with dynabrade ?

By DaC in forum Machine Polishing & SandingReplies: 36Last Post: 10-03-2012, 02:54 AM -

machine polisher?

By jpieps in forum Car DetailingReplies: 17Last Post: 04-26-2010, 10:22 PM -

looking to buy a machine polisher which one?

By nick the swede in forum Car DetailingReplies: 29Last Post: 04-29-2009, 09:58 AM

Reply With Quote

Reply With Quote

Bookmarks